Table of Contents

Merits of Using smooth shaft traverse unit in Industrial Applications

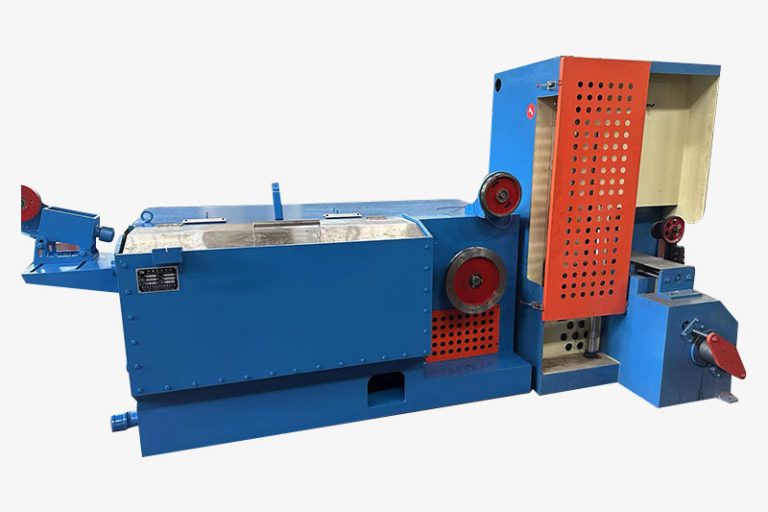

Smooth shaft traverse units are an essential component in many industrial applications, providing a reliable and efficient way to move materials along a production line. These units offer a number of advantages that make them a popular choice for manufacturers looking to streamline their operations and improve productivity.

One of the key merits of using a smooth shaft traverse unit is its ability to provide smooth and precise movement of materials. This is essential in industries where accuracy is paramount, such as in the manufacturing of electronic components or medical devices. The smooth shaft design ensures that materials are transported without any jerky or uneven movements, reducing the risk of damage or errors in the production process.

In addition to providing smooth movement, smooth shaft traverse units are also highly durable and reliable. Made from high-quality materials such as stainless steel or aluminum, these units are built to withstand the rigors of industrial use and can operate continuously for long periods of time without experiencing any issues. This reliability is crucial in industries where downtime can be costly, as it helps to ensure that production lines keep running smoothly and efficiently.

Another advantage of using smooth shaft traverse units is their versatility. These units can be easily customized to suit the specific needs of a particular application, with options available for different shaft lengths, diameters, and materials. This flexibility makes smooth shaft traverse units suitable for a wide range of industries and applications, from food processing to automotive manufacturing.

Smooth shaft traverse units are also easy to install and maintain, requiring minimal downtime for servicing or repairs. This is important for manufacturers looking to maximize their production efficiency and minimize disruptions to their operations. With regular maintenance and care, smooth shaft traverse units can provide years of reliable service, helping to improve overall productivity and profitability.

In conclusion, smooth shaft traverse units offer a number of advantages that make them an ideal choice for industrial applications. From their smooth and precise movement to their durability, reliability, and versatility, these units provide a cost-effective solution for manufacturers looking to optimize their production processes. By investing in smooth shaft traverse units, companies can improve efficiency, reduce downtime, and ultimately increase their bottom line.

How to Properly Maintain and Troubleshoot Smooth Shaft Traverse Unit in Machinery

Smooth Shaft Traverse Unit: How to Properly Maintain and Troubleshoot in Machinery

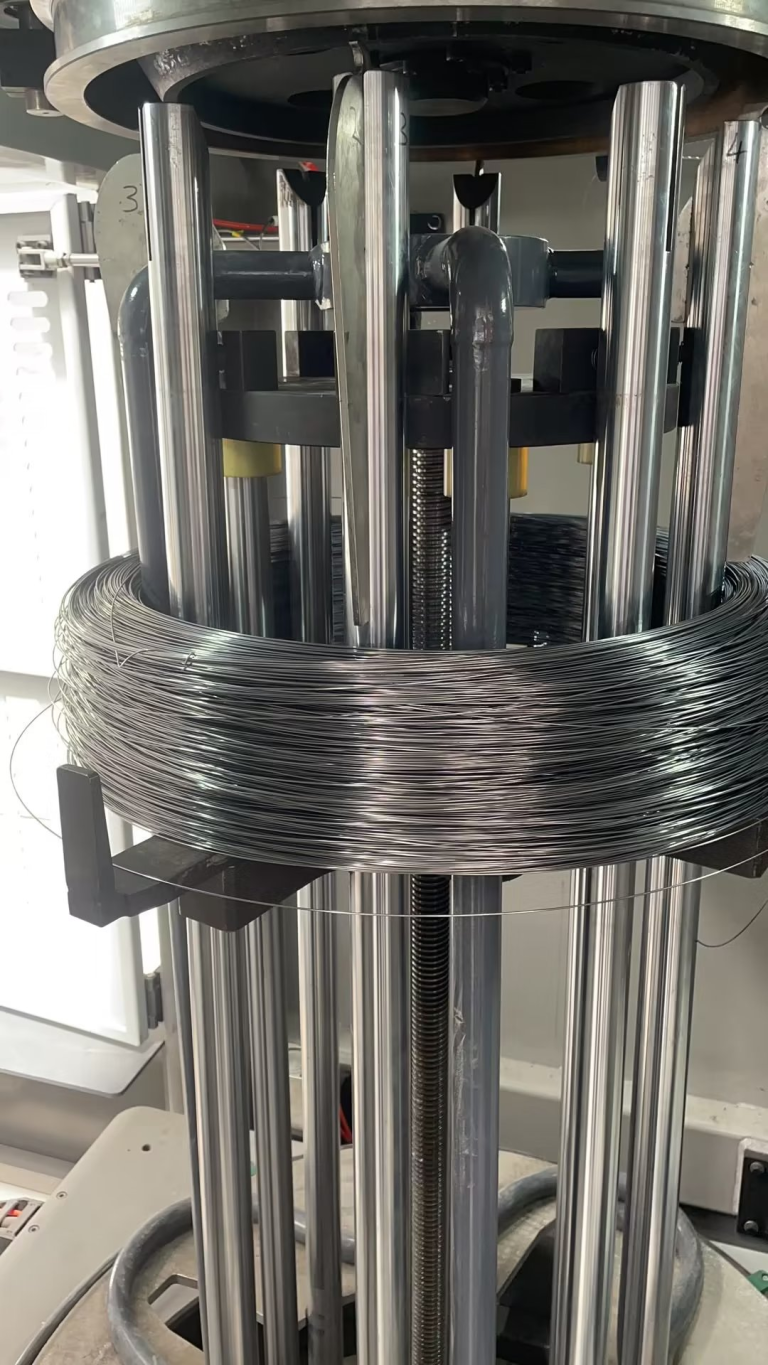

Smooth shaft traverse units are essential components in machinery that are responsible for moving materials back and forth in a controlled manner. Proper maintenance and troubleshooting of these units are crucial to ensure the smooth operation of the machinery and prevent costly breakdowns. In this article, we will discuss some tips on how to properly maintain and troubleshoot smooth shaft traverse units in machinery.

Regular maintenance is key to keeping smooth shaft traverse units in good working condition. One of the most important maintenance tasks is to regularly lubricate the shaft and bearings to reduce friction and wear. This can be done using a high-quality lubricant that is suitable for the specific type of shaft and bearings used in the unit. It is also important to check for any signs of wear or damage on the shaft and bearings and replace them if necessary.

In addition to lubrication, it is important to regularly inspect the unit for any loose or damaged parts. This includes checking the alignment of the shaft and bearings, as well as ensuring that all fasteners are tight and secure. Any loose or damaged parts should be repaired or replaced immediately to prevent further damage to the unit.

Another important maintenance task is to clean the unit regularly to remove any dirt, debris, or other contaminants that can cause damage to the shaft and bearings. This can be done using a soft brush or cloth to gently clean the unit and remove any buildup of dirt or debris. It is also important to avoid using harsh chemicals or solvents when cleaning the unit, as these can cause damage to the shaft and bearings.

In addition to regular maintenance, it is also important to troubleshoot any issues that may arise with the smooth shaft traverse unit. One common issue that can occur is a misalignment of the shaft and bearings, which can cause the unit to operate inefficiently or not at all. This can be corrected by adjusting the alignment of the shaft and bearings to ensure that they are properly aligned and moving smoothly.

Another common issue that can occur is a lack of lubrication, which can cause the shaft and bearings to wear prematurely and lead to costly repairs. If this is the case, it is important to lubricate the unit immediately and check for any signs of wear or damage on the shaft and bearings. If necessary, the shaft and bearings should be replaced to prevent further damage to the unit.

In conclusion, proper maintenance and troubleshooting of smooth shaft traverse units are essential to ensure the smooth operation of machinery. By regularly lubricating, inspecting, and cleaning the unit, as well as troubleshooting any issues that may arise, you can prevent costly breakdowns and keep your machinery running smoothly. Remember to always follow the manufacturer’s guidelines for maintenance and troubleshooting to ensure the best performance of your smooth shaft traverse unit.