Table of Contents

How to Properly Maintain and Care for Rotating Die Holders in Wire Drawing Machines

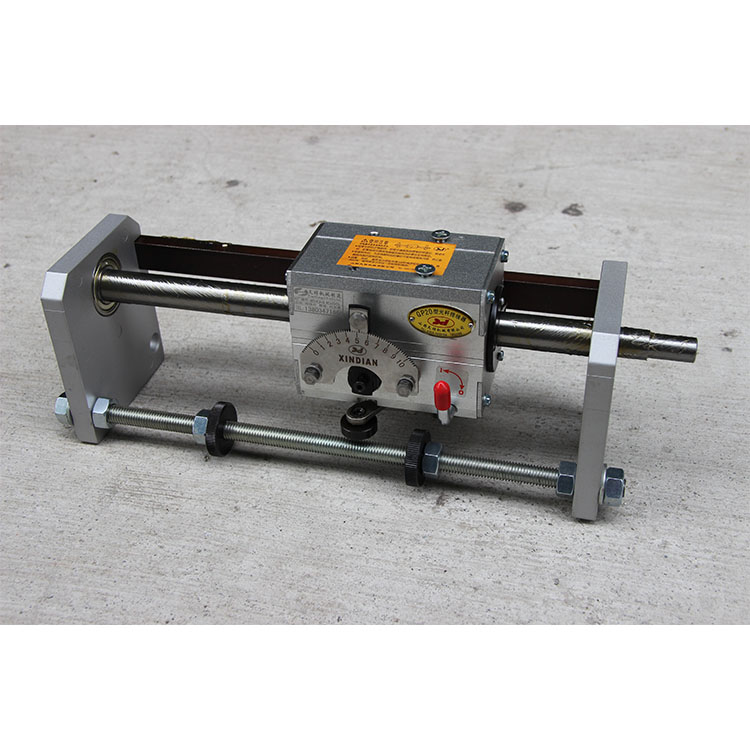

Rotating die holders are an essential component of wire drawing machines, responsible for holding the dies in place and ensuring a smooth and efficient wire drawing process. Proper maintenance and care of these rotating die holders are crucial to the overall performance and longevity of the wire drawing machine. In this article, we will discuss some key tips on how to properly maintain and care for rotating die holders in wire drawing machines.

One of the most important aspects of maintaining rotating die holders is regular cleaning. Over time, dirt, debris, and metal shavings can build up on the die holders, causing them to become less effective and potentially damaging the dies. To prevent this, it is essential to clean the rotating die holders regularly using a soft brush or cloth to remove any buildup. Additionally, using a mild solvent can help to dissolve any stubborn residue and ensure that the die holders are clean and free from debris.

In addition to cleaning, it is also important to inspect the rotating die holders for any signs of wear or damage. Check for any cracks, dents, or other abnormalities that may affect the performance of the die holders. If any issues are found, it is crucial to address them promptly to prevent further damage to the wire drawing machine. In some cases, it may be necessary to replace the rotating die holders to ensure optimal performance.

Another key aspect of maintaining rotating die holders is lubrication. Proper lubrication is essential to ensure that the die holders rotate smoothly and efficiently during the wire drawing process. It is recommended to use a high-quality lubricant specifically designed for use with rotating die holders. Apply the lubricant sparingly to avoid excess buildup, which can attract dirt and debris. Regularly lubricating the rotating die holders will help to prolong their lifespan and ensure that they continue to operate effectively.

In addition to regular cleaning, inspection, and lubrication, it is also important to store rotating die holders properly when not in use. Store them in a clean, dry environment away from moisture and extreme temperatures. This will help to prevent rust and corrosion, which can damage the die holders and affect their performance. Additionally, storing the rotating die holders properly will help to prolong their lifespan and ensure that they are ready for use when needed.

Overall, proper maintenance and care of rotating die holders are essential to the overall performance and longevity of wire drawing machines. By following these key tips, you can ensure that your rotating die holders operate smoothly and efficiently, allowing you to produce high-quality wire products consistently. Remember to clean, inspect, lubricate, and store the rotating die holders properly to maximize their lifespan and maintain optimal performance. With regular maintenance and care, your rotating die holders will continue to perform effectively and contribute to the success of your wire drawing operations.

Advantages of Using Rotating Die Holders in Wire Drawing Machines

Wire drawing machines are essential tools in the manufacturing industry, used to reduce the diameter of various materials such as metal wires, rods, and tubes. One crucial component of wire drawing machines is the die holder, which holds the drawing dies through which the material is pulled to achieve the desired diameter. Traditional die holders are fixed in place, requiring the operator to manually adjust the dies when changing wire sizes. However, rotating die holders offer several advantages over their fixed counterparts, making them a popular choice among manufacturers.

One of the primary advantages of using rotating die holders in wire drawing machines is the ability to quickly and easily change dies. With fixed die holders, operators must stop the machine, remove the existing dies, and install new ones, a time-consuming process that can lead to production downtime. In contrast, rotating die holders allow for rapid die changes without stopping the machine, increasing efficiency and reducing downtime. This is particularly beneficial in industries where frequent die changes are necessary to accommodate different wire sizes or materials.

Another advantage of rotating die holders is the ability to adjust the angle of the dies during operation. This feature allows operators to optimize the wire drawing process by controlling the material flow and reducing friction between the dies and the wire. By adjusting the die angle, manufacturers can achieve a more uniform wire diameter and improve the overall quality of the finished product. Additionally, the ability to adjust the die angle can help extend the life of the dies by reducing wear and tear, ultimately saving on maintenance costs.

Rotating die holders also offer improved die cooling compared to fixed die holders. The rotating motion of the dies helps dissipate heat generated during the wire drawing process, preventing overheating and prolonging the life of the dies. This is especially important when working with materials that are prone to heat damage, such as certain types of metals. By keeping the dies cool, rotating die holders help maintain consistent wire quality and reduce the risk of defects in the finished product.

In addition to these operational advantages, rotating die holders also offer ergonomic benefits for machine operators. The ability to adjust the dies without stopping the machine reduces the physical strain on operators and improves overall workplace safety. Furthermore, the rotating motion of the dies can help reduce vibration and noise levels, creating a more comfortable working environment for operators. These ergonomic benefits not only contribute to a more efficient production process but also help promote a healthier and safer workplace for employees.

Overall, the advantages of using rotating die holders in wire drawing machines are clear. From increased efficiency and productivity to improved wire quality and die longevity, rotating die holders offer a range of benefits that make them a valuable investment for manufacturers. By incorporating rotating die holders into their wire drawing machines, manufacturers can streamline their production processes, enhance product quality, and create a safer and more comfortable working environment for their employees.