Table of Contents

How to Properly Maintain and Care for Rotary Die Holders

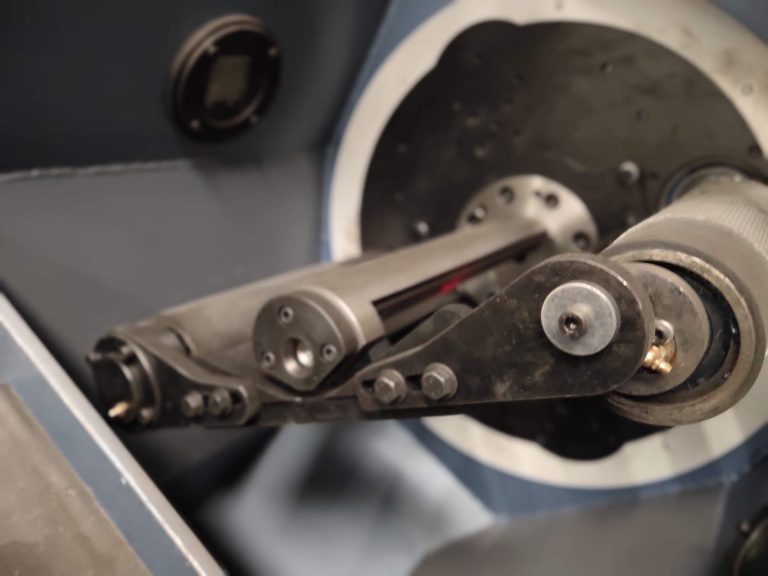

Rotating Die Holders are essential tools in the manufacturing industry, used for cutting, scoring, and perforating various materials such as paper, cardboard, and plastic. Proper maintenance and care of rotary die holders are crucial to ensure their longevity and optimal performance. In this article, we will discuss some key tips on how to properly maintain and care for rotary die holders.

One of the most important aspects of maintaining Rotating Die Box is regular cleaning. Over time, dust, debris, and adhesive residue can build up on the die holder, affecting its cutting precision and efficiency. To clean the die holder, use a soft brush or cloth to remove any debris and then wipe it down with a mild solvent or cleaning solution. Be sure to dry the die holder thoroughly before using it again to prevent any damage.

In addition to regular cleaning, it is also important to inspect the rotary die holder for any signs of wear or damage. Check for any cracks, dents, or scratches on the surface of the die holder, as these can affect its cutting performance. If you notice any damage, it is important to address it promptly to prevent further issues. In some cases, you may need to replace the die holder altogether if the damage is severe.

Another key aspect of maintaining rotary die unit is proper storage. When not in use, store the die holder in a clean, dry place away from direct sunlight and moisture. Avoid storing the die holder in areas with extreme temperatures, as this can cause the material to warp or degrade over time. Additionally, make sure to store the die holder in a secure location to prevent any accidental damage.

When using rotary die holders, it is important to follow the manufacturer’s guidelines for proper usage. Avoid overloading the die holder with materials that are too thick or hard, as this can cause premature wear and damage. Use the appropriate cutting pressure and speed for the material being cut to ensure clean and precise cuts. If you are unsure about the proper settings, consult the manufacturer’s instructions or seek guidance from a professional.

Regular maintenance of rotary die holders also includes lubrication. Apply a small amount of lubricant to the moving parts of the die holder to reduce friction and wear. Be sure to use a lubricant that is compatible with the material of the die holder to prevent any damage. Avoid over-lubricating the die holder, as this can attract dust and debris, leading to potential issues.

In conclusion, proper maintenance and care of rotary die holders are essential to ensure their longevity and optimal performance. By following these key tips, you can keep your die holder in top condition and prolong its lifespan. Regular cleaning, inspection, proper storage, following manufacturer guidelines, and lubrication are all important aspects of maintaining rotary die holders. By taking care of your die holder, you can ensure smooth and efficient cutting operations for years to come.

Tips for Choosing the Right Rotary Die Holder for Your Specific Needs

Rotary die holders are essential tools in the manufacturing industry, used for holding rotary dies securely in place during the cutting process. Choosing the right rotary die holder for your specific needs is crucial to ensure efficient and precise cutting operations. With a wide range of options available on the market, it can be overwhelming to select the best one for your application. In this article, we will provide you with some tips to help you choose the right rotary die holder for your specific needs.

First and foremost, it is important to consider the size and type of rotary die that you will be using with the holder. Rotary dies come in various sizes and shapes, so it is essential to choose a holder that is compatible with the die you will be using. Make sure to measure the dimensions of your rotary die accurately before purchasing a holder to ensure a proper fit.

Another important factor to consider is the material of the rotary die holder. Rotary die holders are typically made from materials such as steel, aluminum, or plastic. The material you choose will depend on the type of cutting operation you will be performing. Steel holders are durable and long-lasting, making them ideal for heavy-duty cutting applications. Aluminum holders are lightweight and corrosion-resistant, making them suitable for applications where weight is a concern. Plastic holders are cost-effective and easy to replace, but may not be as durable as steel or aluminum holders.

In addition to the material, you should also consider the design of the rotating die box. Some holders come with adjustable features that allow you to customize the cutting depth and pressure, while others have fixed settings. Adjustable holders offer more flexibility and precision, making them ideal for applications that require fine-tuning. On the other hand, fixed holders are simpler to use and are suitable for basic cutting operations.

When choosing a rotary die holder, it is also important to consider the mounting options available. Some holders come with a magnetic base that allows for easy attachment to a cutting machine, while others require mounting brackets or screws for installation. Make sure to choose a holder that is compatible with your cutting machine and offers a secure mounting solution to prevent any accidents during operation.

Lastly, consider the brand and reputation of the manufacturer when choosing a rotary die holder. Opt for a reputable manufacturer that has a track record of producing high-quality products and providing excellent customer support. Reading reviews and testimonials from other users can also help you gauge the quality and performance of a particular rotary die holder.

In conclusion, choosing the right rotary die holder for your specific needs requires careful consideration of factors such as size, material, design, mounting options, and manufacturer reputation. By following these tips, you can select a rotary die holder that meets your requirements and ensures efficient and precise cutting operations. Remember to always prioritize safety and quality when selecting a rotary die holder for your manufacturing processes.

Benefits of Using Rotary Die Holders in Manufacturing Processes

Rotary die holders are an essential tool in the manufacturing industry, providing numerous benefits that can streamline production processes and improve overall efficiency. These holders are designed to securely hold rotary dies in place, allowing for precise cutting and shaping of materials such as paper, cardboard, plastic, and metal. By using rotating die unit, manufacturers can achieve consistent and high-quality results, leading to increased productivity and cost savings.

One of the key benefits of using rotary die holders is their ability to accommodate a wide range of die sizes and shapes. This versatility allows manufacturers to use different dies for various applications without the need for multiple holders. By simply swapping out the dies, operators can quickly change the cutting or shaping process, saving time and reducing downtime. This flexibility is especially valuable in industries where production requirements may vary frequently.

In addition to their versatility, rotary die holders are also known for their precision and accuracy. The holders are designed to securely grip the dies in place, ensuring that they remain stable during the cutting process. This stability helps to prevent errors and inconsistencies in the finished products, resulting in higher quality output. With rotary die holders, manufacturers can achieve tight tolerances and intricate designs with ease, making them an essential tool for industries that require precision cutting and shaping.

Another benefit of using rotary die holders is their durability and longevity. Made from high-quality materials such as steel or aluminum, these holders are built to withstand the rigors of daily use in a manufacturing environment. Their robust construction ensures that they can handle the demands of heavy-duty cutting operations without succumbing to wear and tear. This durability not only extends the lifespan of the holders but also reduces the need for frequent replacements, saving manufacturers time and money in the long run.

Furthermore, rotary die holders are designed for ease of use, making them accessible to operators of all skill levels. The holders are typically equipped with features such as quick-release mechanisms and adjustable settings, allowing for fast and simple die changes and adjustments. This user-friendly design helps to streamline production processes and minimize the risk of errors caused by operator fatigue or inexperience. By investing in rotary die holders, manufacturers can empower their workforce to work more efficiently and effectively, leading to improved overall productivity.

In conclusion, rotary die holders offer a wide range of benefits that can significantly enhance manufacturing processes. From their versatility and precision to their durability and ease of use, these holders are a valuable tool for industries that rely on cutting and shaping materials. By incorporating rotary die holders into their operations, manufacturers can achieve consistent and high-quality results, increase productivity, and reduce costs. With their numerous advantages, rotary die holders are a must-have for any manufacturing facility looking to optimize their production processes and stay ahead of the competition.