Table of Contents

Merits of Using Reversed Bending Descaler for Industrial Equipment

Industrial equipment is essential for the smooth operation of various industries, from manufacturing to energy production. However, over time, these machines can accumulate scale and deposits that can hinder their performance and efficiency. To combat this issue, many industries turn to descaling solutions to remove these deposits and restore the equipment to optimal working condition.

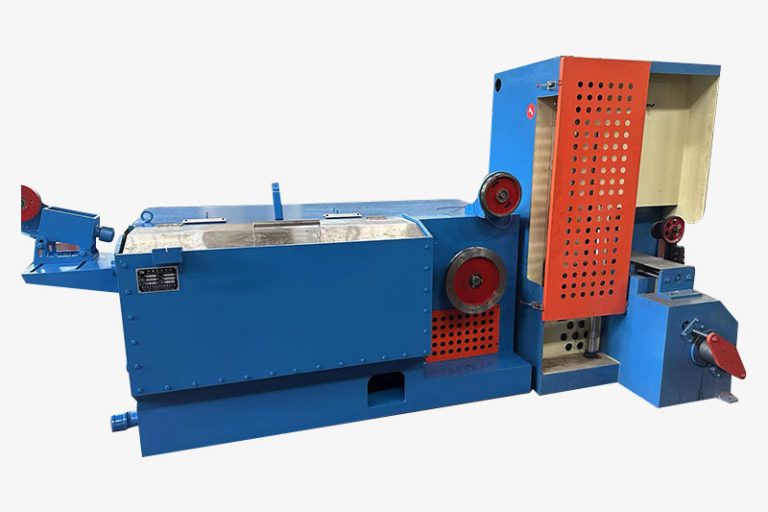

One popular descaling method is the reversed bending descaler, which offers several benefits for industrial equipment. This innovative technology uses a unique process to effectively remove scale and deposits from pipes, boilers, heat exchangers, and other equipment without causing damage or corrosion. In this article, we will explore the benefits of using a reversed bending descaler for industrial equipment.

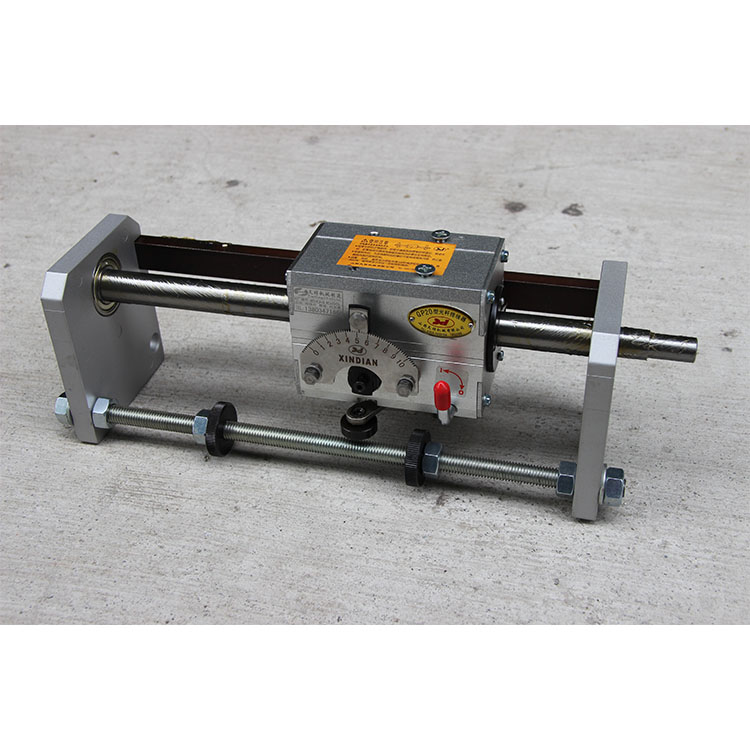

One of the primary advantages of using a reversed bending descaler is its ability to clean hard-to-reach areas within industrial equipment. Traditional descaling methods may struggle to effectively remove scale from tight corners or complex geometries, leading to incomplete cleaning and potential performance issues. The reversed bending descaler, however, uses a flexible shaft with a rotating head that can navigate through intricate pathways and thoroughly clean all surfaces, ensuring a comprehensive descaling process.

Furthermore, the reversed bending descaler is a non-invasive descaling solution that does not require the disassembly of equipment for cleaning. This not only saves time and labor costs but also minimizes downtime for industrial operations. By using a reversed bending descaler, industries can maintain their equipment’s efficiency and productivity without the need for extensive maintenance procedures.

In addition to its cleaning capabilities, the reversed bending descaler is also environmentally friendly. Traditional descaling methods often involve the use of harsh chemicals that can be harmful to the environment and pose health risks to workers. In contrast, the reversed bending descaler uses a water-based descaling solution that is safe and non-toxic, making it a sustainable choice for industrial cleaning applications.

Another benefit of using a reversed bending descaler is its versatility. This descaling technology can be used on a wide range of industrial equipment, including boilers, condensers, evaporators, and heat exchangers. Whether in the manufacturing, energy, or chemical industry, the reversed bending descaler can effectively remove scale and deposits from various types of equipment, ensuring optimal performance and longevity.

Furthermore, the reversed bending descaler is a cost-effective descaling solution for industries. By preventing scale buildup and maintaining equipment efficiency, industries can avoid costly repairs and replacements in the long run. Investing in a reversed bending descaler can help industries save money on maintenance and extend the lifespan of their equipment, ultimately improving their bottom line.

In conclusion, the reversed bending descaler offers numerous benefits for industrial equipment cleaning. From its ability to clean hard-to-reach areas to its environmentally friendly and cost-effective nature, this descaling technology is a valuable tool for industries looking to maintain their equipment’s performance and efficiency. By incorporating a reversed bending descaler into their maintenance routine, industries can ensure the longevity and reliability of their industrial equipment for years to come.

Step-by-Step Guide on How to Properly Use Reversed Bending Descaler for Effective Cleaning

Reversed bending descaler is a powerful tool used for cleaning various surfaces, particularly those that are prone to scaling and buildup. This innovative cleaning method involves the use of a specialized descaling agent that is applied to the surface in a reversed bending motion, allowing for thorough and effective cleaning. In this article, we will provide a step-by-step guide on how to properly use reversed bending descaler for optimal results.

To begin, it is important to ensure that you have the necessary equipment and materials on hand before starting the cleaning process. This includes the reversed bending descaler, protective gloves, goggles, and a brush or scrubbing pad for scrubbing away any stubborn buildup. It is also recommended to wear protective clothing to prevent any contact with the descaling agent.

The first step in using reversed bending descaler is to prepare the surface that needs to be cleaned. This may involve removing any loose debris or dirt from the surface, as well as ensuring that the area is well-ventilated to prevent the buildup of fumes from the descaling agent. Once the surface is prepared, it is time to apply the descaler.

To apply the descaler, simply spray or pour the solution onto the surface in a reversed bending motion. This motion helps to ensure that the descaling agent reaches all areas of the surface, allowing for thorough cleaning. It is important to apply the descaler evenly and generously to ensure that all areas are covered.

After applying the descaler, allow it to sit on the surface for a few minutes to allow it to penetrate and break down any stubborn buildup. During this time, you may notice the descaler foaming or bubbling, which is a sign that it is working to dissolve the scale and grime on the surface. Once the descaler has had time to work its magic, it is time to scrub the surface.

Using a brush or scrubbing pad, gently scrub the surface in a reversed bending motion to help loosen and remove any remaining buildup. Be sure to pay special attention to areas that are particularly dirty or scaled, as these may require additional scrubbing. It is important to use a gentle but firm pressure when scrubbing to avoid damaging the surface.

After scrubbing the surface, rinse it thoroughly with clean water to remove any remaining descaler and residue. It is important to rinse the surface well to ensure that no descaler is left behind, as this can cause damage or discoloration over time. Once the surface is rinsed, allow it to dry completely before using it again.

In conclusion, reversed bending descaler is a highly effective cleaning method that can help to remove stubborn scale and buildup from various surfaces. By following the steps outlined in this article, you can ensure that you are using reversed bending descaler properly and effectively for optimal cleaning results. Remember to always wear protective gear and follow the manufacturer’s instructions when using descaling agents to ensure safety and effectiveness.