Table of Contents

Advantages of Using Reverse Twisted Barbed Wire Machines

Barbed wire has been a staple in fencing and security applications for over a century. Its ability to deter intruders and keep livestock contained has made it a popular choice for farmers, ranchers, and property owners alike. One of the key components of barbed wire is the twist that gives it its characteristic sharp edges. Traditional barbed wire machines twist the wire in a clockwise direction, but there is another option available – reverse twisted barbed wire machines.

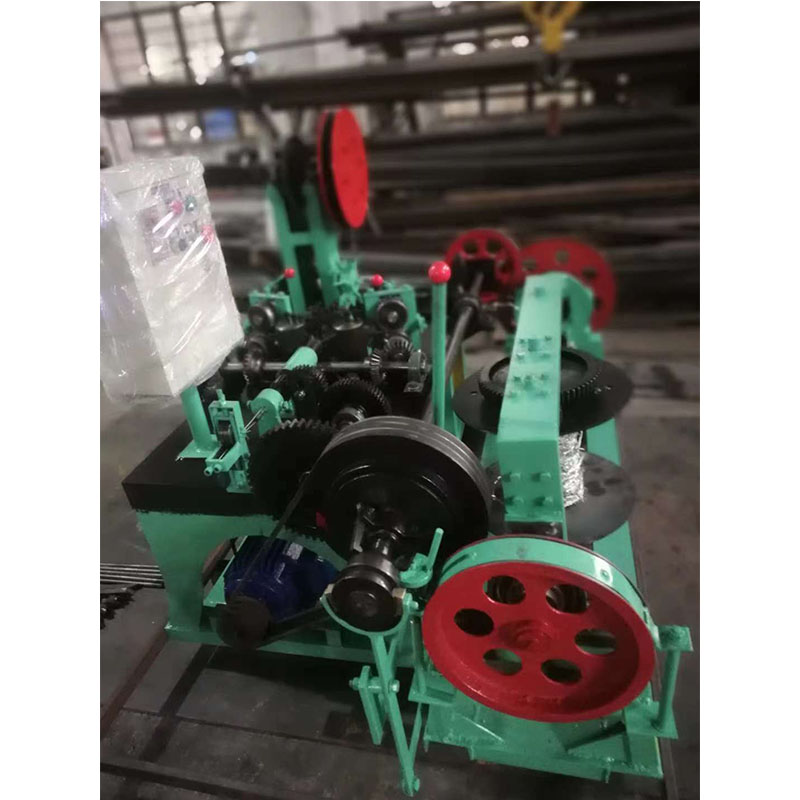

Reverse twisted barbed wire machines operate in the opposite direction, twisting the wire in a counterclockwise motion. This may seem like a small difference, but it can have a significant impact on the quality and performance of the barbed wire produced. One of the main advantages of using reverse twisted barbed wire machines is the increased strength and durability of the wire. By twisting the wire in the opposite direction, the barbs are more securely attached to the wire, making it harder to break or bend. This can be especially important in high-security applications where the integrity of the fence is crucial.

Another advantage of reverse twisted barbed wire machines is the ability to produce longer lengths of barbed wire in a single run. Because the wire is twisted in the opposite direction, it can be wound more tightly onto the spools, allowing for longer continuous lengths to be produced. This can save time and labor costs, as fewer splices are needed to connect shorter lengths of wire together.

In addition to increased strength and longer lengths, reverse twisted barbed wire machines also offer improved safety features. The reverse twisting motion helps to prevent the wire from unraveling or becoming tangled during production, reducing the risk of accidents or injuries. This can be especially important in industrial settings where large quantities of barbed wire are being produced.

Furthermore, reverse twisted barbed wire machines are more versatile than traditional machines. They can accommodate a wider range of wire gauges and materials, allowing for greater flexibility in the types of barbed wire that can be produced. This can be beneficial for manufacturers who need to produce different types of barbed wire for various applications.

Overall, the advantages of using reverse twisted barbed wire machines are clear. They offer increased strength and durability, the ability to produce longer lengths of wire, improved safety features, and greater versatility. These machines are a valuable tool for anyone in need of high-quality barbed wire for fencing or security purposes.

In conclusion, reverse twisted barbed wire machines are a superior option for producing high-quality barbed wire. Their unique twisting motion results in stronger, more durable wire that is safer to produce and more versatile in its applications. Whether you are a farmer, rancher, or property owner in need of secure fencing, or a manufacturer looking to produce top-quality barbed wire, consider investing in a reverse twisted barbed wire machine for superior results.

How to Properly Maintain and Clean Reverse Twisted Barbed Wire Machines

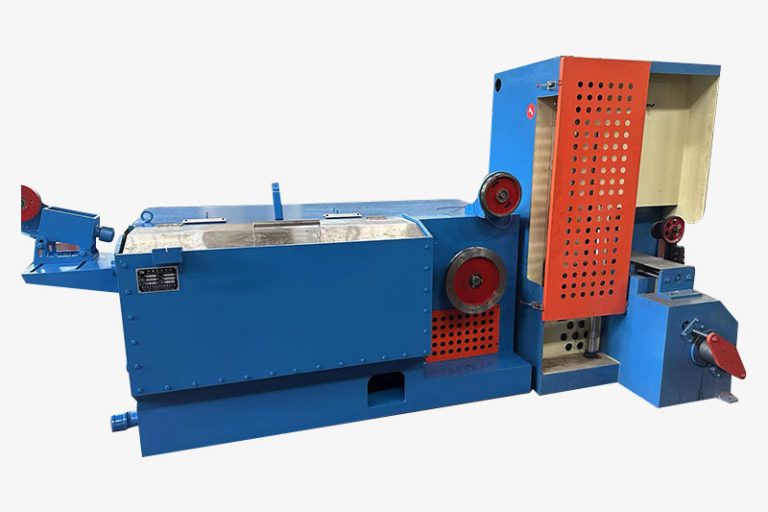

Reverse twisted barbed wire machines are essential tools for creating strong and durable barbed wire fences. These machines are designed to efficiently twist and weave wires together to form the sharp and protective barbs that deter intruders and keep livestock contained. Proper maintenance and cleaning of these machines are crucial to ensure their longevity and optimal performance. In this article, we will discuss the importance of maintaining and cleaning reverse twisted barbed wire machines, as well as provide some tips on how to do so effectively.

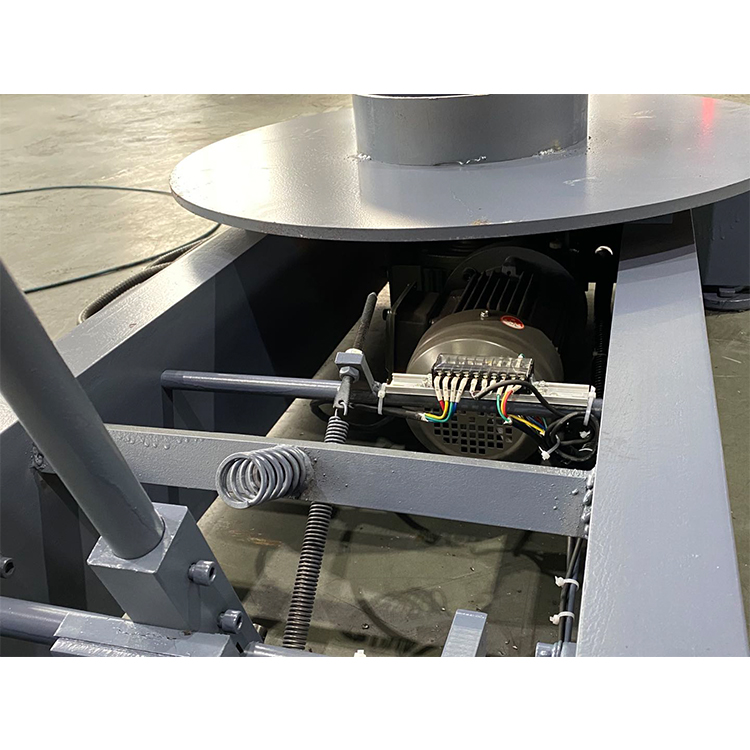

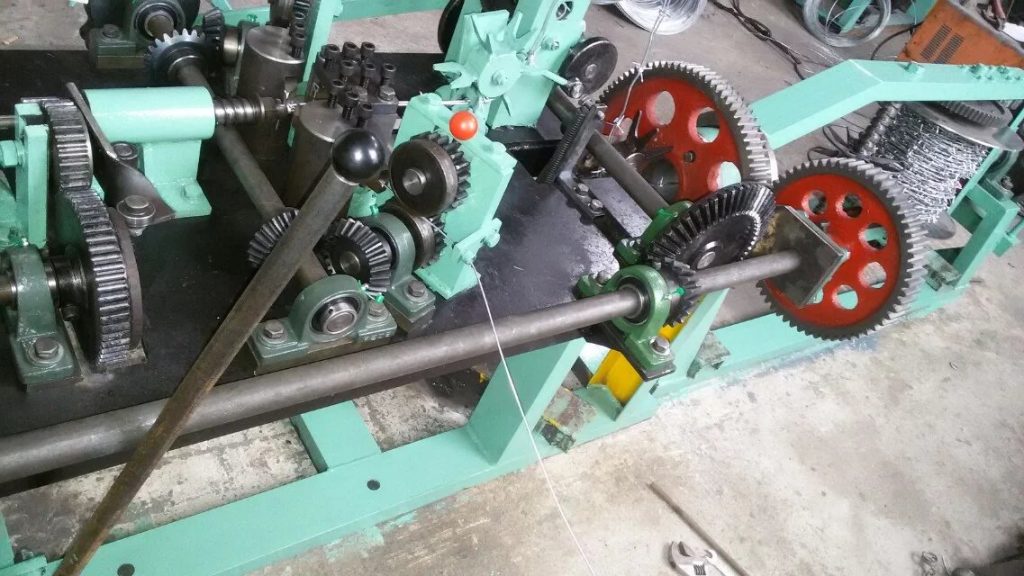

Regular maintenance of reverse twisted barbed wire machines is essential to prevent breakdowns and ensure smooth operation. One of the most important maintenance tasks is lubricating the moving parts of the machine. This helps reduce friction and wear on the components, prolonging their lifespan. It is recommended to use a high-quality lubricant that is specifically designed for industrial machinery.

In addition to lubrication, it is important to regularly inspect the machine for any signs of wear or damage. Check for loose or missing bolts, worn-out gears, and damaged wires. Replace any worn or damaged parts immediately to prevent further damage to the machine. It is also a good idea to clean the machine regularly to remove any dirt, debris, or rust that may have accumulated.

Cleaning reverse twisted barbed wire machines is a relatively simple process, but it is important to do it correctly to avoid damaging the machine. Start by unplugging the machine and removing any excess wire or debris from the working area. Use a soft brush or cloth to gently wipe down the machine, paying special attention to the moving parts and wire guides. Avoid using harsh chemicals or abrasive materials, as these can damage the machine’s components.

After cleaning the machine, it is important to properly store it to prevent rust and corrosion. Keep the machine in a dry and well-ventilated area, away from moisture and direct sunlight. Cover the machine with a tarp or protective cover to keep dust and debris out. It is also a good idea to periodically inspect the machine while it is in storage to ensure that it remains in good condition.

In addition to regular maintenance and cleaning, it is important to follow the manufacturer’s guidelines for operating the machine. This includes using the correct wire gauge and type, as well as following proper safety procedures. Always wear appropriate safety gear, such as gloves and eye protection, when operating the machine. Never attempt to modify or repair the machine yourself, as this can void the warranty and potentially cause harm.

By following these tips for maintaining and cleaning reverse twisted barbed wire machines, you can ensure that your machine remains in good working condition for years to come. Proper maintenance not only prolongs the lifespan of the machine but also ensures that it operates efficiently and safely. Remember to regularly inspect, lubricate, and clean the machine, and always follow the manufacturer’s guidelines for operation. With proper care and maintenance, your reverse twisted barbed wire machine will continue to provide reliable performance for all your fencing needs.

Common Issues and Troubleshooting Tips for Reverse Twisted Barbed Wire Machines

Reverse twisted barbed wire machines are essential tools in the manufacturing of barbed wire, a common fencing material used to secure properties and livestock. These machines are designed to twist two wires together in opposite directions, creating a sharp and effective deterrent against intruders. However, like any piece of machinery, reverse twisted barbed wire machines can encounter issues that may affect their performance. In this article, we will discuss some common problems that may arise with these machines and provide troubleshooting tips to help resolve them.

One of the most common issues with reverse twisted barbed wire machines is wire breakage. This can occur due to a variety of reasons, such as improper tension settings, worn-out components, or a misalignment of the machine. To troubleshoot this issue, start by checking the tension settings on the machine and adjusting them as needed. Make sure that the wires are properly aligned and that there are no obstructions in the path of the wires. If the issue persists, inspect the machine for any worn-out components that may need to be replaced.

Another common issue with reverse twisted barbed wire machines is uneven twisting of the wires. This can result in a poorly constructed barbed wire that may not provide adequate security. To troubleshoot this issue, check the alignment of the wires as they pass through the machine. Make sure that the wires are entering the machine at the correct angle and that they are being twisted evenly. Adjust the tension settings on the machine to ensure that both wires are being twisted at the same rate. If the issue continues, inspect the machine for any damaged or worn-out components that may be causing the uneven twisting.

In some cases, reverse twisted barbed wire machines may experience jamming or clogging issues. This can be caused by a buildup of debris or tangled wires within the machine. To troubleshoot this issue, carefully inspect the machine for any obstructions and remove them as needed. Clean the machine regularly to prevent debris from accumulating and causing jams. If the issue persists, check the alignment of the wires and adjust the tension settings to ensure smooth operation.

One final common issue with reverse twisted barbed wire machines is motor failure. This can be a serious problem that may require professional repair or replacement of the motor. If you suspect that the motor is failing, stop using the machine immediately and contact a qualified technician for assistance. Regular maintenance and inspection of the machine can help prevent motor failure and other serious issues from occurring.

In conclusion, reverse twisted barbed wire machines are valuable tools in the manufacturing of barbed wire fencing. However, like any piece of machinery, they can encounter issues that may affect their performance. By following the troubleshooting tips outlined in this article, you can address common problems with reverse twisted barbed wire machines and ensure that they continue to operate effectively. Regular maintenance and inspection of the machine are key to preventing issues and prolonging the lifespan of this essential tool.