Table of Contents

Advantages of Using Pulley Type Wire Drawing Machines in Chinese High Grade Factories

Pulley type wire drawing machines are a crucial piece of equipment in Chinese high-grade factories. These machines are used to draw wire through a series of dies to reduce its diameter and improve its quality. There are several advantages to using pulley type wire drawing machines in these factories, including increased efficiency, improved quality of the wire, and reduced maintenance costs.

One of the main advantages of using pulley type wire drawing machines in Chinese high-grade factories is their efficiency. These machines are designed to operate at high speeds, allowing for quick and precise wire drawing. This increased efficiency means that more wire can be produced in a shorter amount of time, leading to higher productivity and lower production costs. Additionally, pulley type wire drawing machines are able to draw wire to very precise diameters, ensuring that the final product meets the required specifications.

Another advantage of using pulley type wire drawing machines is the improved quality of the wire produced. These machines are able to draw wire with a high degree of precision, resulting in a smoother surface finish and more consistent diameter. This improved quality makes the wire more suitable for use in high-grade applications, such as in the automotive or aerospace industries. Additionally, the use of pulley type wire drawing machines can help to reduce the occurrence of defects in the wire, leading to a higher quality final product.

In addition to their efficiency and quality benefits, pulley type wire drawing machines also offer cost savings for Chinese high-grade factories. These machines require less maintenance than other types of wire drawing equipment, reducing downtime and maintenance costs. Additionally, the high-speed operation of pulley type wire drawing machines means that less energy is required to produce the same amount of wire, leading to lower energy costs. Overall, the use of pulley type wire drawing machines can help Chinese high-grade factories to reduce their production costs and improve their bottom line.

In conclusion, pulley type wire drawing machines offer several advantages for Chinese high-grade factories. These machines are able to operate at high speeds, leading to increased efficiency and productivity. They also produce wire with a high degree of precision and quality, making it suitable for use in high-grade applications. Additionally, pulley type wire drawing machines require less maintenance and energy, leading to cost savings for factories. Overall, the use of pulley type wire drawing machines can help Chinese high-grade factories to improve their production processes and produce high-quality wire for a variety of applications.

How Pulley Type Wire Drawing Machines Improve Efficiency and Quality in Chinese High Grade Factories

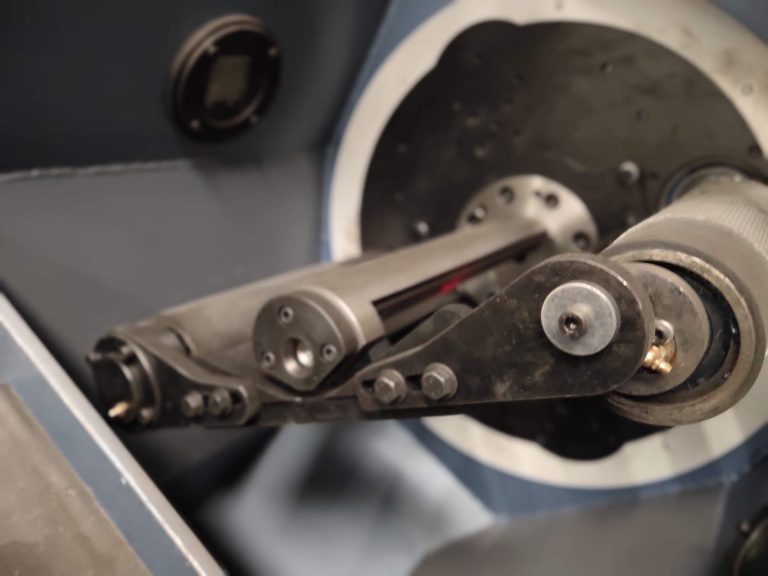

Pulley type wire drawing machines have become an essential tool in Chinese high-grade factories for improving efficiency and quality in the production of wire products. These machines are designed to pull wire through a series of dies to reduce its diameter and improve its surface finish. By utilizing pulleys to control the speed and tension of the wire, these machines are able to produce wire with consistent dimensions and properties, making them ideal for use in a wide range of industries.

One of the key advantages of pulley type wire drawing machines is their ability to increase production efficiency. By using multiple dies in a series, these machines are able to reduce the diameter of the wire in a single pass, saving time and energy compared to traditional methods that require multiple passes through different dies. This not only speeds up the production process but also reduces the amount of waste material generated, leading to cost savings for the factory.

In addition to improving efficiency, pulley type wire drawing machines also play a crucial role in enhancing the quality of the wire produced. By controlling the speed and tension of the wire as it passes through the dies, these machines are able to produce wire with a smooth surface finish and consistent dimensions. This is essential for industries that require high-quality wire products, such as the automotive, aerospace, and electronics industries, where even minor variations in wire diameter or surface finish can lead to product defects or failures.

Furthermore, pulley type wire drawing machines are highly versatile and can be used to produce wire from a wide range of materials, including steel, copper, aluminum, and titanium. This flexibility allows Chinese high-grade factories to meet the diverse needs of their customers and produce wire products for a variety of applications. Whether it’s for electrical wiring, fencing, or industrial machinery, pulley type wire drawing machines can be customized to produce wire with the specific properties required for each application.

Another benefit of using pulley type wire drawing machines in Chinese high-grade factories is their durability and reliability. These machines are built to withstand the rigors of continuous operation and are designed to require minimal maintenance, ensuring that they can operate efficiently for extended periods of time. This reliability is essential for factories that rely on consistent production to meet customer demand and maintain their competitive edge in the market.

In conclusion, pulley type wire drawing machines have become an indispensable tool for improving efficiency and quality in Chinese high-grade factories. By utilizing pulleys to control the speed and tension of the wire, these machines are able to produce wire with consistent dimensions and properties, making them ideal for use in a wide range of industries. With their ability to increase production efficiency, enhance wire quality, and provide versatility and reliability, pulley type wire drawing machines are a valuable asset for any factory looking to optimize its wire production process.