High speed copper coating production line for CO2 welding wire line

The production line is for the production of CO2 welding wire, from diameter 5.5mm or 6.5mm to finished wire diameter 0.8mm, 1.0mm, 1.2mm or 1.6mm by one-step production with high speed copper coating with speed of 25-30 meters per second.

it includes pay-off, descaler, belt grinding machine, wire drawing line, wire cleaning line, copper coating line, skin pass and take-up.

the total length of the production line be 65 meters.

High Speed Copper Coating Production Line For CO2 Welding Wire Line

A .Summery

Copper coating production line are composed by ZWF-630 self-damp pay-off machine, wire carrying pulleys, copper coating tank assembly, traction & polishing machine and ZWS-630 wire take-up spooler, and also blowing system is set. The number of lines depends on customers demand and the dimension of workshop site.

- B .Pay-off machine

With the function of buffering and tension control, it plays a role to pay-off wire through wire carrying pulleys into copper coating tank assembly. There is no driving force in the machine; there is a self-adjusting mechanical device to adjust the speed of rotating.

- Copper Coating tank assembly

Copper coating tank assembly is composed by the following:

Metal wool brushing tank-2m

Water-cleaning tank (room temperature water)-2m

Alkali-cleaning tank (degreasing), first tank-10m and second tank-10m

Hot-water washing tank-2m

Water-washing tank (room temperature water)-2m

Acid-washing tank-10m

Activation tank-6m

Water- washing tank (room temperature water)-2m

Copper coating tank (first coating-6m and second coating-10m)

Water- washing tank (room temperature water)-2m

Neutralizing tank-2.5m

Water- washing tank (room temperature water)-2m

Hot-water washing tank-2.5m

Drying tank-8m

For each tank, it is divided into working tank (upper) and storage tank (lower), and the liquid between two tanks is circulated by pump. And also inlet and outlet taps are set for each tank.

Electrical heating system is adopted for some of tanks.

Blowers are set between tanks, so as to prevent liquid on wire into other tanks.

Ceramic U type wire carriers are set between different wires.

Metal wool brushing tank (tank body material: PPR plastic sheet)

Medium: A-Stainless steel scrubber

Function: this is the first tank that the semi-product wire goes into, and the wire goes through the medium and into the next tank, friction happens between the wire surface and the medium, so it makes the lubricant (left onside the wire surface during wire drawing process) loose, at the same time, there are water showing system, so it remove the lubricant.

Water-cleaning (tank body material: PPR plastic sheet)

Medium: water

Function: to remove the remaining lubricant onside the surface of wires.

Alkali-cleaning tank (degreasing), first tank and second tank

Medium: NaOH(180g/L), Na3PO4+Na2CO3(20g/L) (tank body material: stainless steel plate with thickness of 3.0mm, tank is divided into inner tank and outer tank, there are aluminum silicate fiber between them so as to keep the temperature, DC power electrolysis device is set for the tank, and the liquid is circulating)

Function: chemical reaction happens between lubricant and medium under higher temperature, it makes the lubricant into soap and glycerin, which are more water soluble.

Fist tank and second tank are set, so you can change the solution of first tank more frequently and less frequently for the second tank, in this way, you can save the solution.

Hot-water washing tank

Medium: hot water

Function: by heating the water, to make hot water showing the wires from alkali-cleaning tank, so as to move the alkali solution left onside the wire surface.

(Tank body material: stainless steel plate with thickness of 3.0mm, tank is divided into inner tank and outer tank, there are aluminum silicate fiber between them so as to keep the temperature, DC power electrolysis device is set for the tank, and the liquid is circulating)

Water-washing tank (room temperature water)

Medium: water

Function: to clean the wire surface by showing the wire,

The outlet tap keeps open and the waste water (it is of alkalinity) then will be emitted directly to the sedimentation pond.

The outlet tap keeps open and the waste water (it is acid) then will be emitted directly to the sedimentation pond.

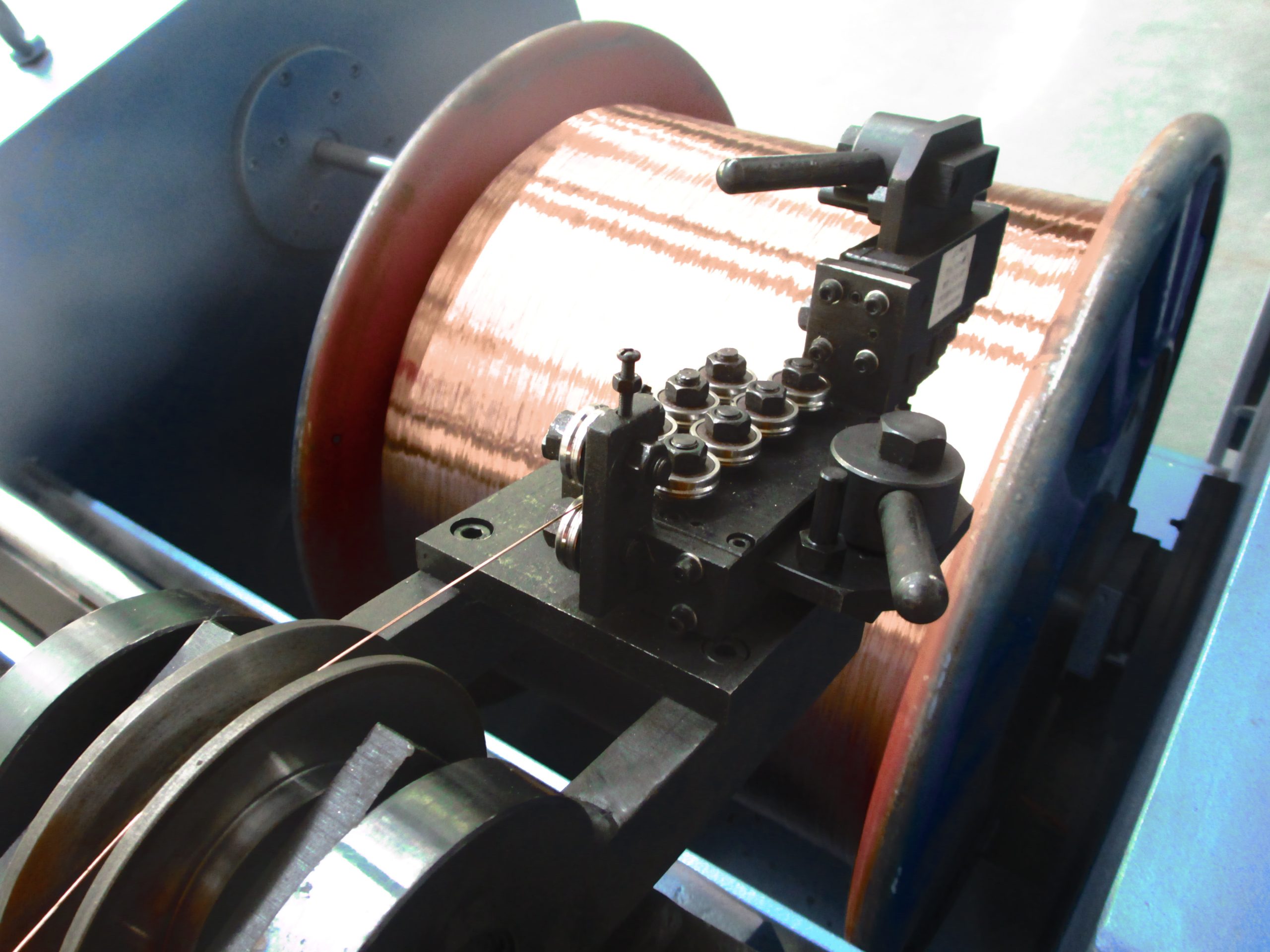

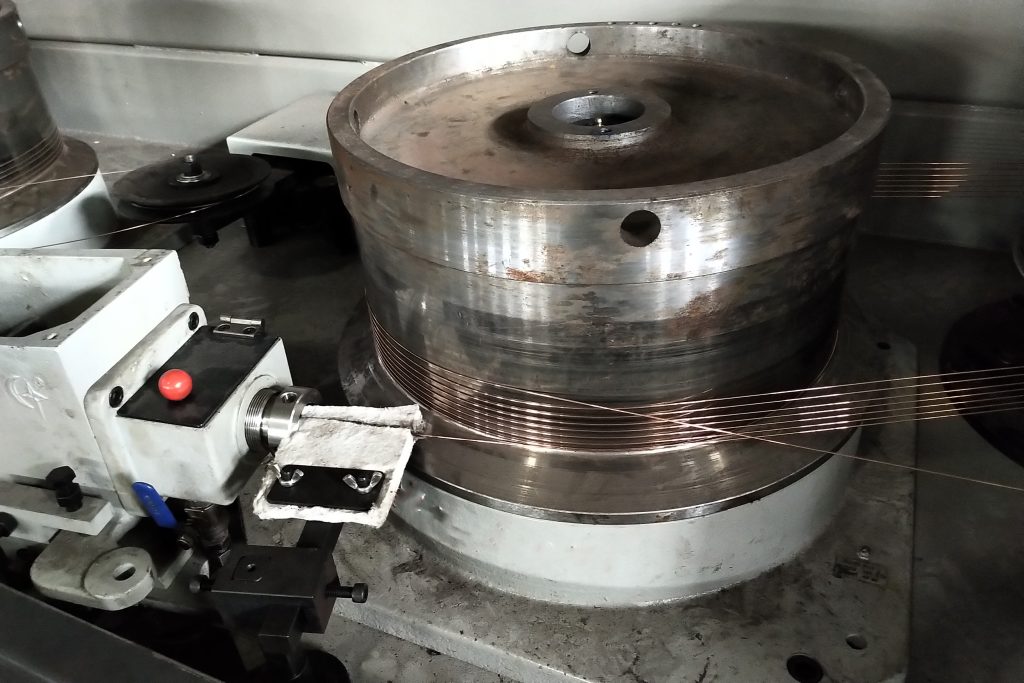

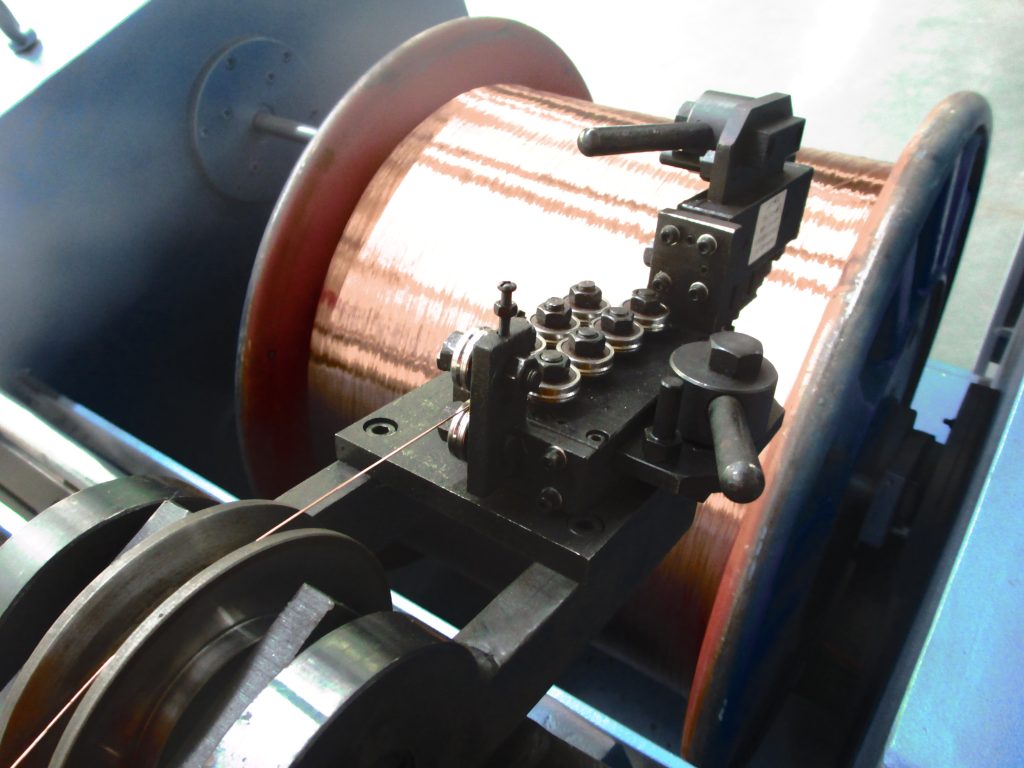

- D. Traction & polishing machine and Take-up spooling machine

Semi-finished wire after copper coating, goes through finish die hole for polishing, and pulled by traction pulley with power of 5.5KW, and then be wound on spools.

- E Blowing system

Drive by two 5.5KW motors, inlet pipe diameter 160mm, outlet pipe diameter 300mm.