Exploring the Benefits of Using a Nail Cutter in Nail Making Machine Accessories

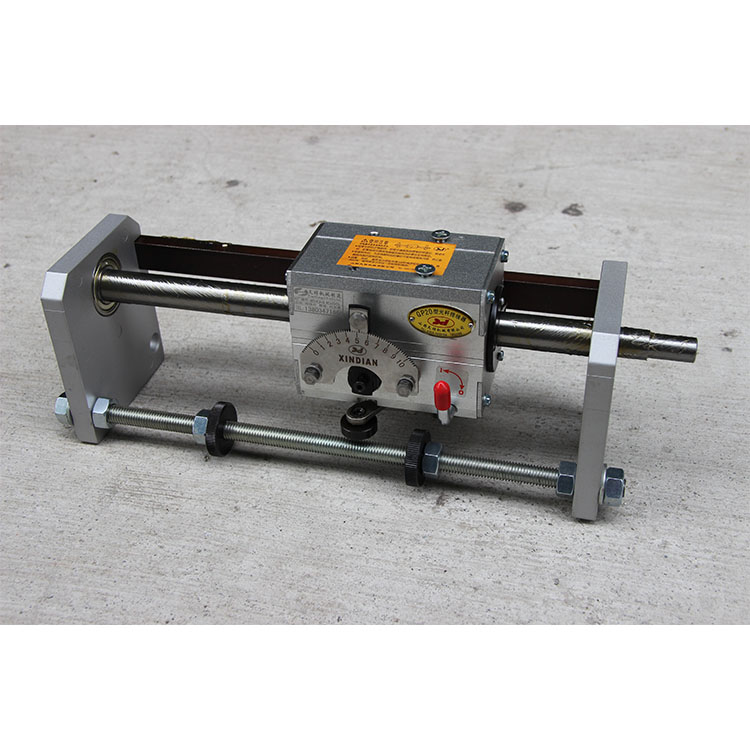

Nail Die is essential tools in the manufacturing industry, allowing for the efficient production of nails in various sizes and shapes. One crucial component of these machines is the nail cutter, which plays a vital role in shaping and cutting the nails to the desired specifications. In this article, we will explore the benefits of using a nail cutter in nail making machine accessories.

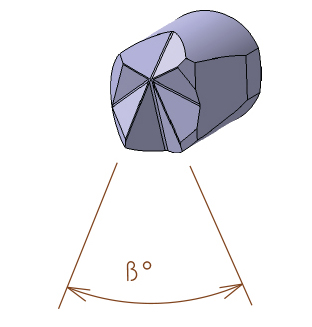

First and foremost, a nail cutter ensures precision and accuracy in the cutting process. By using a nail cutter, manufacturers can produce nails with consistent lengths and shapes, which is essential for ensuring the quality of the final product. This level of precision is difficult to achieve manually and can significantly improve the efficiency of the nail making process.

Additionally, Nail Making Machine Tools are designed to be durable and long-lasting, making them a cost-effective investment for manufacturers. With regular maintenance and proper care, a high-quality nail cutter can last for years, reducing the need for frequent replacements and repairs. This durability not only saves money but also minimizes downtime in production, allowing for a more efficient manufacturing process.

Furthermore, nail cutters are designed to be easy to use and operate, making them suitable for both experienced professionals and beginners. With simple adjustments and settings, operators can quickly change the cutting specifications to meet the requirements of different nail sizes and shapes. This versatility makes nail cutters a valuable tool for manufacturers looking to produce a wide range of nail products.

In addition to precision and durability, nail cutters also offer safety benefits for operators. By using a nail cutter in the nail making process, manufacturers can minimize the risk of accidents and injuries that may occur when cutting nails manually. The automated cutting process of a nail cutter reduces the need for manual handling of sharp objects, creating a safer working environment for operators.

Moreover, nail cutters can help improve the overall efficiency of the nail making process. By automating the cutting process, manufacturers can increase the speed and output of their production, allowing for higher volumes of nails to be produced in a shorter amount of time. This increased efficiency can lead to cost savings and improved profitability for manufacturers.

In conclusion, the benefits of using a nail cutter in nail making machine accessories are numerous. From precision and durability to safety and efficiency, nail cutters play a crucial role in the manufacturing process, ensuring high-quality nail products are produced consistently. By investing in a high-quality nail cutter, manufacturers can improve the overall quality of their products, reduce costs, and increase productivity. Ultimately, a nail cutter is an essential tool for any manufacturer looking to streamline their nail making process and achieve success in the industry.