Merits of Using a Mechanical Wire Descaler in Industrial Applications

In industrial applications where metal wire is used, the process of descaling is crucial to ensure the quality and efficiency of the final product. Mechanical wire descalers are a popular choice for this task, offering a range of benefits that make them a valuable tool in the manufacturing process.

One of the key advantages of using a mechanical wire descaler is its ability to remove scale and other surface impurities from metal wire quickly and efficiently. This helps to improve the overall quality of the wire, ensuring that it meets the required specifications for the intended application. By removing scale and other contaminants, mechanical wire descalers help to prevent issues such as corrosion and surface defects, which can compromise the integrity of the final product.

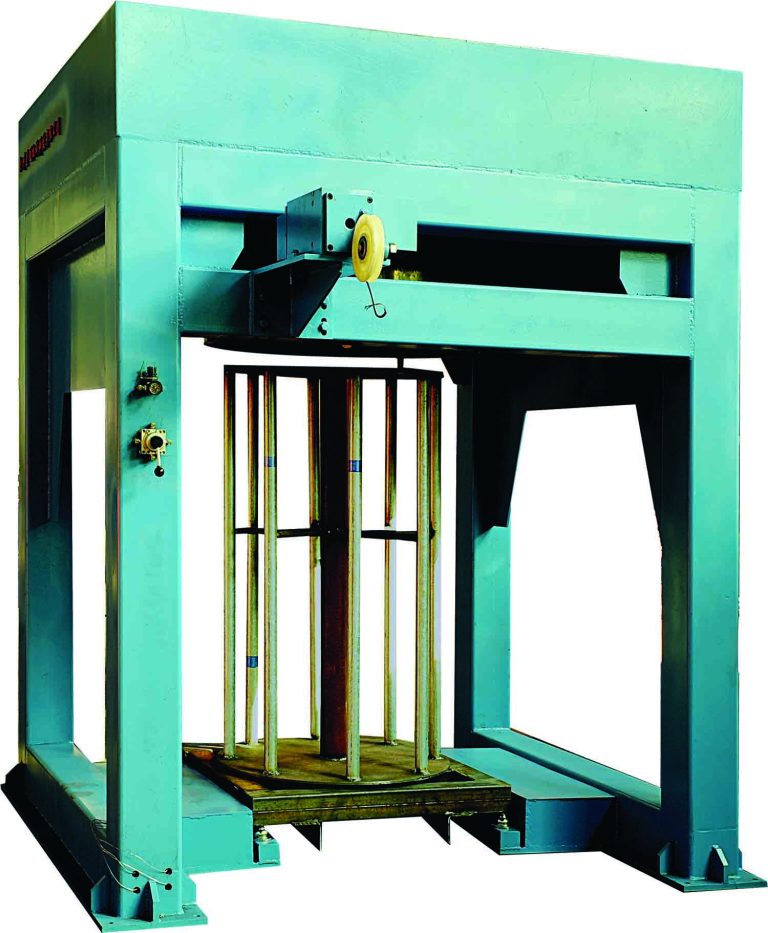

In addition to improving the quality of the wire, mechanical Wire Rod Descaling Machine also help to increase the efficiency of the manufacturing process. By removing scale and other impurities from the wire, these machines help to reduce the amount of material that is wasted during production. This not only helps to save money on raw materials but also helps to increase the overall productivity of the manufacturing process. With a mechanical wire descaler, manufacturers can produce high-quality wire more quickly and cost-effectively, helping to improve their bottom line.

Another benefit of using a mechanical wire descaler is its versatility. These machines are capable of descaling a wide range of wire sizes and materials, making them suitable for a variety of industrial applications. Whether you are working with steel, aluminum, copper, or another type of metal wire, a mechanical wire descaler can help you achieve the desired results. This versatility makes these machines a valuable investment for manufacturers who work with a variety of materials in their production processes.

Furthermore, mechanical wire descalers are easy to operate and maintain, making them a convenient option for industrial applications. These machines are designed to be user-friendly, with intuitive controls and simple maintenance requirements. This helps to reduce downtime and ensure that the descaling process runs smoothly and efficiently. With a mechanical wire descaler, manufacturers can focus on their core operations without having to worry about complicated machinery or time-consuming maintenance tasks.

Overall, the benefits of using a mechanical wire descaler in industrial applications are clear. These machines offer a range of advantages, including improved quality, increased efficiency, versatility, and ease of use. By investing in a mechanical wire descaler, manufacturers can enhance the quality and productivity of their production processes, ultimately leading to better results and higher profitability. If you are looking to improve the descaling process in your industrial applications, consider the benefits of using a mechanical wire descaler.