Table of Contents

Advantages of Using Knives for Enkotec Nail Making Machine

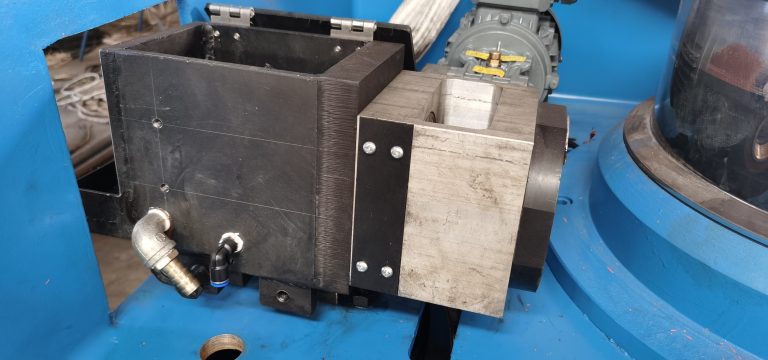

Knives play a crucial role in the operation of Enkotec nail making machines. These machines are widely used in the manufacturing industry to produce high-quality nails efficiently and effectively. Knives are an essential component of these machines, as they are responsible for cutting and shaping the wire into the desired nail shape. In this article, we will discuss the advantages of using knives for Enkotec nail making machines.

One of the primary advantages of using knives for Enkotec nail making machines is their precision and accuracy. Knives are designed to cut the wire with extreme precision, ensuring that each nail is uniform in size and shape. This level of precision is essential in the manufacturing industry, where consistency and quality are paramount. By using knives, manufacturers can produce nails that meet the highest standards and specifications.

Another advantage of using knives for Enkotec nail making machines is their durability and longevity. Knives are made from high-quality materials that are designed to withstand the rigors of continuous use. This durability ensures that the knives remain sharp and effective for an extended period, reducing the need for frequent replacements. By using durable knives, manufacturers can minimize downtime and increase productivity, ultimately leading to cost savings and improved efficiency.

In addition to precision and durability, knives for Enkotec nail making machines offer versatility and flexibility. These knives can be customized to meet the specific requirements of different nail shapes and sizes. Manufacturers can choose from a variety of knife designs and configurations to produce nails of varying lengths, diameters, and head shapes. This flexibility allows manufacturers to adapt to changing market demands and produce a wide range of nail products to meet customer needs.

Furthermore, knives for Enkotec nail making machines are easy to maintain and replace. With regular maintenance and sharpening, knives can remain sharp and effective for an extended period. In the event that a knife becomes dull or damaged, it can be easily replaced with a new one, minimizing downtime and ensuring continuous production. This ease of maintenance and replacement makes knives a cost-effective and efficient tool for nail manufacturers.

Overall, the advantages of using knives for Enkotec nail making machines are clear. From precision and accuracy to durability and flexibility, knives play a crucial role in the production of high-quality nails. By investing in high-quality knives and maintaining them properly, manufacturers can achieve consistent results, increase productivity, and meet customer demands effectively. Knives are an essential component of Enkotec nail making machines, and their benefits are undeniable in the manufacturing industry.

Maintenance Tips for Knives in Enkotec Nail Making Machine

Knives are an essential component of the Enkotec nail making machine, as they are responsible for cutting and shaping the nails during the manufacturing process. Proper maintenance of these knives is crucial to ensure the machine operates efficiently and produces high-quality nails. In this article, we will discuss some maintenance tips for knives in the Enkotec nail making machine.

First and foremost, it is important to regularly inspect the knives for any signs of wear or damage. Over time, the cutting edges of the knives can become dull or chipped, which can affect the quality of the nails produced. If any damage is detected, the knives should be replaced immediately to prevent further issues.

In addition to regular inspections, the knives should also be cleaned and lubricated on a regular basis. Dirt, debris, and rust can accumulate on the knives, which can affect their performance. Cleaning the knives with a soft brush and a mild solvent can help remove any buildup and keep them in good condition. After cleaning, the knives should be lubricated with a high-quality oil to ensure smooth operation.

Another important maintenance tip for knives in the Enkotec nail making machine is to ensure proper alignment. Misaligned knives can cause uneven cutting and result in nails that are not uniform in size and shape. To check the alignment of the knives, a straight edge can be used to ensure that all the knives are in the correct position. If any misalignment is detected, the knives should be adjusted accordingly.

It is also important to monitor the cutting speed of the knives in the Enkotec nail making machine. Running the machine at too high of a speed can cause excessive wear on the knives and lead to premature failure. It is recommended to follow the manufacturer’s guidelines for the optimal cutting speed to ensure the longevity of the knives.

Additionally, it is important to handle the knives with care to prevent damage. Rough handling or dropping the knives can cause them to become bent or damaged, which can affect their performance. When handling the knives, it is important to use caution and avoid any unnecessary force.

Lastly, it is important to keep a record of the maintenance performed on the knives in the Enkotec nail making machine. Keeping track of when the knives were last inspected, cleaned, and replaced can help ensure that they are properly maintained and replaced in a timely manner. This can help prevent unexpected downtime and ensure that the machine continues to operate efficiently.

In conclusion, proper maintenance of the knives in the Enkotec nail making machine is essential to ensure the machine operates efficiently and produces high-quality nails. By following these maintenance tips, operators can prolong the life of the knives and prevent costly repairs. Regular inspections, cleaning, lubrication, alignment checks, monitoring cutting speed, careful handling, and keeping records of maintenance are all important steps in maintaining the knives in the Enkotec nail making machine.

How to Choose the Right Knives for Enkotec Nail Making Machine

When it comes to choosing the right knives for your Enkotec nail making machine, there are several factors to consider in order to ensure optimal performance  and longevity of the machine. Knives are a critical component of the nail making process, as they are responsible for cutting and shaping the wire into the desired nail shape. Selecting the right knives for your Enkotec machine can make a significant difference in the quality and efficiency of your nail production.

and longevity of the machine. Knives are a critical component of the nail making process, as they are responsible for cutting and shaping the wire into the desired nail shape. Selecting the right knives for your Enkotec machine can make a significant difference in the quality and efficiency of your nail production.

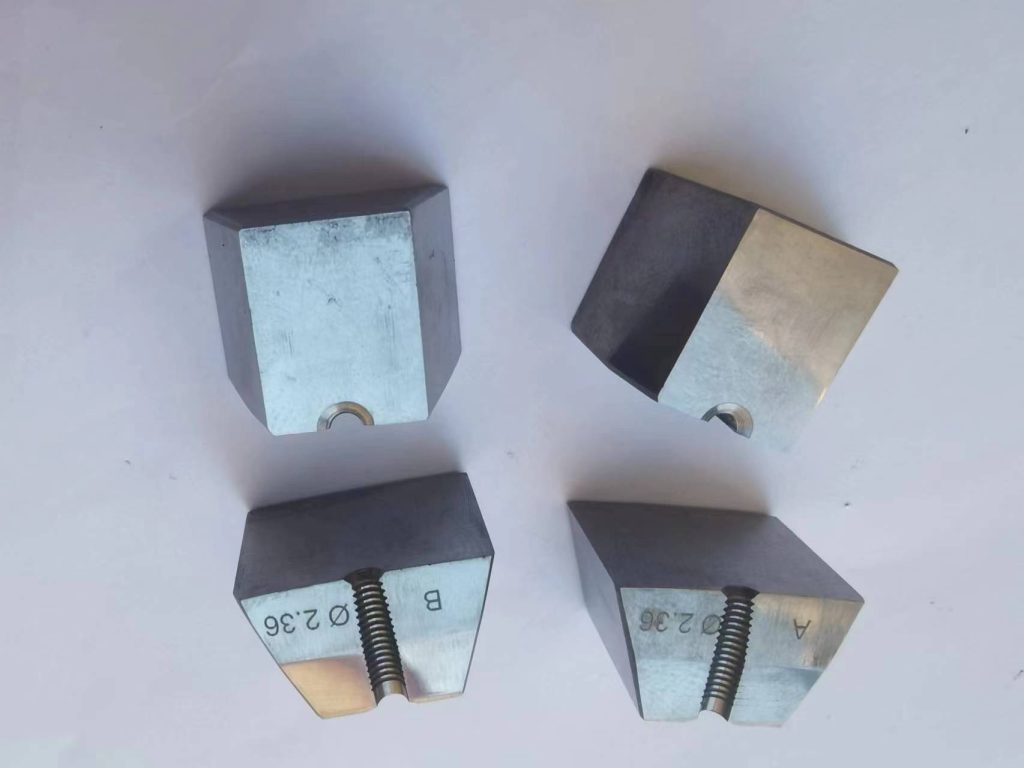

One of the first things to consider when choosing knives for your Enkotec nail making machine is the material of the knives. The material of the knives will determine their durability and resistance to wear and tear. It is important to choose knives made from high-quality materials such as tool steel or carbide, as these materials are known for their hardness and ability to maintain a sharp edge for a longer period of time. Investing in high-quality knives may require a higher upfront cost, but it can ultimately save you money in the long run by reducing the frequency of knife replacements and downtime.

Another important factor to consider when selecting knives for your Enkotec machine is the type of nail you will be producing. Different nail shapes and sizes require different types of knives with specific cutting profiles. It is essential to choose knives that are designed to produce the specific nail shape you need, whether it be common nails, finishing nails, or specialty nails. Using the wrong type of knives can result in poor nail quality, increased waste, and potential damage to the machine.

In addition to material and type, the size and dimensions of the knives are also crucial considerations when choosing knives for your Enkotec nail making machine. The size of the knives should be compatible with the machine and the wire diameter you will be working with. Using knives that are too small or too large can lead to improper cutting and shaping of the wire, resulting in defective nails and potential damage to the machine. It is important to consult the machine’s manual or manufacturer for guidance on the appropriate knife size and dimensions for your specific Enkotec model.

Furthermore, the sharpness of the knives is a key factor in the performance of your Enkotec nail making machine. Dull knives can lead to uneven cuts, jagged edges, and increased friction, which can cause overheating and premature wear of the machine components. Regular maintenance and sharpening of the knives are essential to ensure consistent and high-quality nail production. Investing in a quality knife sharpening system or outsourcing knife sharpening services can help prolong the life of your knives and maintain the efficiency of your Enkotec machine.

In conclusion, choosing the right knives for your Enkotec nail making machine is a critical decision that can impact the quality, efficiency, and longevity of your nail production. By considering factors such as material, type, size, dimensions, and sharpness, you can ensure that your machine operates at its best and produces high-quality nails consistently. Investing in high-quality knives and proper maintenance can help maximize the performance of your Enkotec machine and ultimately save you time and money in the long run.