Table of Contents

Advantages of Using Horizontal Bobbin Spooling Machines

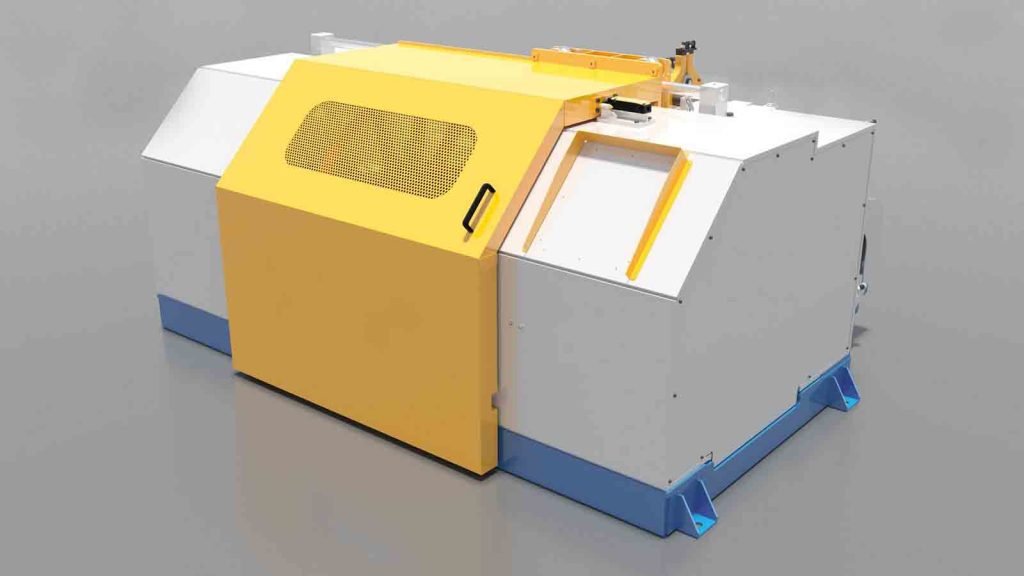

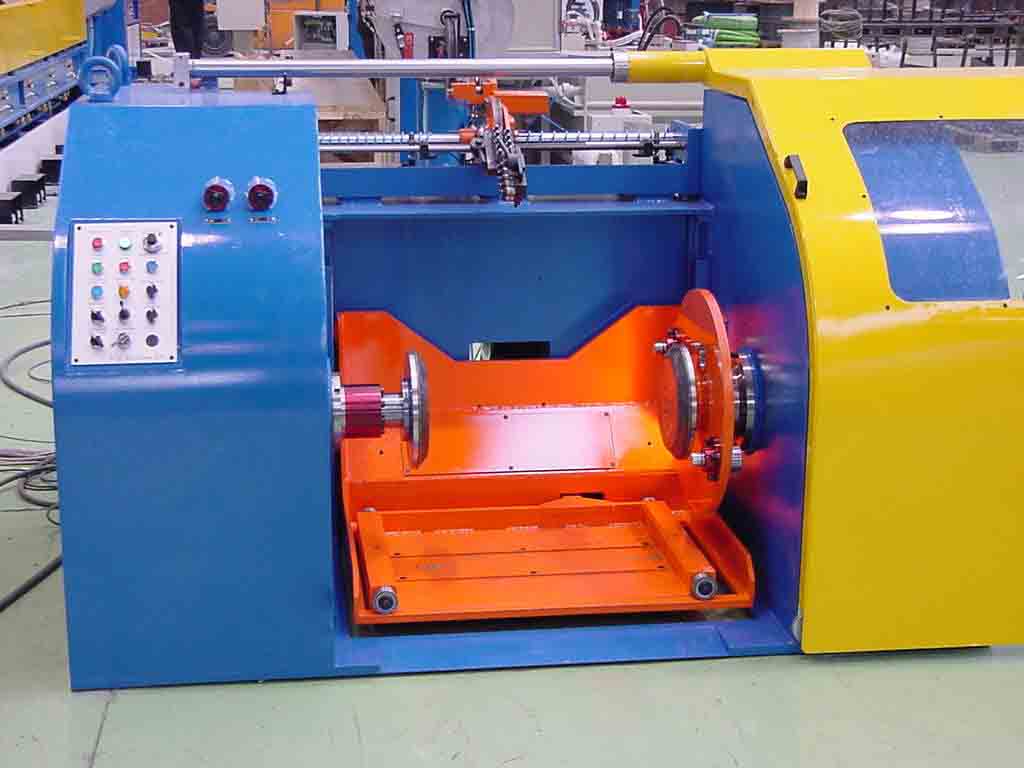

Horizontal Spooling Machine are a crucial piece of equipment in the textile industry. These machines are used to wind yarn onto bobbins, which are then used in various textile processes such as weaving and knitting. There are several advantages to using horizontal bobbin spooling machines, which make them a popular choice among textile manufacturers.

One of the main advantages of horizontal bobbin spooling machines is their efficiency. These machines are designed to wind yarn onto bobbins quickly and accurately, saving time and labor costs for textile manufacturers. The horizontal design of these machines allows for smooth and continuous winding of yarn, resulting in a high-quality finished product.

In addition to their efficiency, HORIZONTAL Wire Spooling Machine are also known for their versatility. These machines can be used to wind a wide range of yarn types and sizes, making them suitable for a variety of textile applications. Whether manufacturers are working with fine silk yarn or thick wool yarn, horizontal bobbin spooling machines can handle the job with ease.

Another advantage of using horizontal bobbin spooling machines is their durability. These machines are built to withstand the rigors of daily use in a textile manufacturing environment. With proper maintenance and care, horizontal bobbin spooling machines can last for many years, providing a reliable and consistent winding solution for manufacturers.

Furthermore, horizontal bobbin spooling machines are easy to operate and maintain. These machines are designed with user-friendly controls and features, making them accessible to operators of all skill levels. Additionally, routine maintenance tasks such as cleaning and lubrication are straightforward and can be performed by in-house maintenance staff.

The compact size of horizontal bobbin spooling machines is another advantage that makes them a popular choice among textile manufacturers. These machines can be easily integrated into existing production lines, saving valuable floor space in the manufacturing facility. The small footprint of horizontal bobbin spooling machines also makes them portable and easy to move around the production floor as needed.

In conclusion, horizontal bobbin spooling machines offer several advantages that make them an essential piece of equipment in the textile industry. From their efficiency and versatility to their durability and ease of operation, these machines provide a reliable and cost-effective solution for winding yarn onto bobbins. With their compact size and user-friendly design, horizontal bobbin spooling machines are a valuable asset for textile manufacturers looking to streamline their production processes and improve overall efficiency.

How to Properly Maintain Horizontal Bobbin Spooling Machines

Horizontal bobbin Respooling Machine is essential tools in the textile industry for winding yarn onto bobbins. Proper maintenance of these machines is crucial to ensure their longevity and efficiency. In this article, we will discuss some key maintenance tips to help you keep your horizontal bobbin spooling machines in top working condition.

One of the most important aspects of maintaining a horizontal bobbin spooling machine is regular cleaning. Dust, lint, and other debris can accumulate on the machine over time, leading to decreased performance and potential damage. It is recommended to clean the machine after each use, paying special attention to the bobbin winding area and the tensioning mechanisms. Use a soft brush or cloth to remove any buildup and ensure that the machine is free of any obstructions.

In addition to regular cleaning, it is also important to lubricate the moving parts of the machine to prevent wear and tear. Lubrication should be done according to the manufacturer’s recommendations, using the appropriate type of oil or grease. Over-lubrication can attract dust and debris, so be sure to apply the lubricant sparingly and wipe off any excess.

Another key maintenance tip for horizontal bobbin spooling machines is to regularly check and adjust the tension settings. Proper tension is crucial for achieving consistent winding results and preventing yarn breakage. Make sure that the tensioning mechanisms are in good working order and adjust them as needed to achieve the desired tension level.

It is also important to inspect the machine for any signs of wear or damage on a regular basis. Check for loose or worn parts, such as belts, pulleys, and bearings, and replace them as needed. Keeping an eye on the condition of the machine will help prevent costly repairs and downtime in the future.

In addition to regular maintenance tasks, it is also important to follow proper operating procedures when using a horizontal bobbin spooling machine. Avoid overloading the machine with too many bobbins or running it at excessive speeds, as this can put unnecessary strain on the motor and other components. Always follow the manufacturer’s guidelines for operating the machine to ensure safe and efficient operation.

Proper storage of the machine when not in use is also important for maintaining its condition. Store the machine in a clean, dry environment away from dust and moisture, and cover it with a protective cloth or tarp to prevent damage. If the machine will be stored for an extended period, consider applying a rust inhibitor to prevent corrosion.

By following these maintenance tips, you can ensure that your horizontal bobbin spooling machine remains in top working condition for years to come. Regular cleaning, lubrication, tension adjustments, and inspections are key to preventing breakdowns and ensuring smooth operation. Remember to follow proper operating procedures and store the machine correctly to maximize its lifespan and performance. With proper maintenance, your horizontal bobbin spooling machine will continue to be a valuable asset in your textile production process.

Comparison of Different Brands of Horizontal Bobbin Spooling Machines

Horizontal bobbin spooling machines are essential tools in the textile industry for winding yarn onto bobbins. They play a crucial role in ensuring the efficiency and quality of the production process. There are several brands of horizontal bobbin spooling machines available in the market, each offering unique features and capabilities. In this article, we will compare different brands of horizontal bobbin spooling machines to help you make an informed decision when choosing the right machine for your needs.

One of the leading brands in the horizontal bobbin spooling machine market is Brand A. Brand A is known for its high-quality machines that are durable and reliable. These machines are equipped with advanced technology that allows for precise winding of yarn onto bobbins. They also come with user-friendly interfaces that make operation easy and efficient. Brand A machines are designed to handle a wide range of yarn types and sizes, making them versatile and adaptable to different production needs.

Another popular brand in the horizontal bobbin spooling machine market is Brand B. Brand B machines are known for their speed and efficiency. These machines are equipped with powerful motors that can wind yarn onto bobbins at a fast pace, increasing productivity and reducing downtime. Brand B machines are also designed to be compact and space-saving, making them ideal for small production facilities. Additionally, Brand B machines are easy to maintain and operate, making them a popular choice among textile manufacturers.

Brand C is another well-known brand in the horizontal bobbin spooling machine market. Brand C machines are known for their precision and accuracy. These machines are equipped with advanced sensors and controls that ensure consistent winding tension and yarn placement. Brand C machines are also designed to be energy-efficient, reducing operating costs and environmental impact. Additionally, Brand C machines are built to last, with durable components that can withstand heavy use and harsh production environments.

When comparing different brands of horizontal bobbin spooling machines, it is important to consider factors such as speed, precision, durability, and ease of operation. Each brand offers unique features and capabilities that cater to different production needs. Brand A machines are known for their versatility and user-friendly interfaces, making them a great choice for manufacturers with diverse production requirements. Brand B machines are ideal for high-speed production environments where efficiency is key. Brand C machines are best suited for manufacturers who prioritize precision and accuracy in their production process.

In conclusion, horizontal bobbin spooling machines are essential tools in the textile industry for winding yarn onto bobbins. When choosing a machine, it is important to consider factors such as speed, precision, durability, and ease of operation. Different brands offer unique features and capabilities that cater to different production needs. By comparing different brands of horizontal bobbin spooling machines, you can make an informed decision and choose the right machine for your specific requirements.