Importance of Auxiliary Equipment in Wire Drawing Process

Wire Brush Descaler Machine is a crucial process in the manufacturing of various wire products, such as electrical wiring, cables, and fencing. This process involves pulling a metal wire through a series of dies to reduce its diameter and improve its mechanical properties. While the main equipment used in wire drawing is the drawing machine itself, auxiliary equipment plays a vital role in ensuring the efficiency and quality of the process.

One of the most important pieces of auxiliary equipment in wire drawing is the wire straightener. As the wire is pulled through the dies, it can become bent or twisted, which can affect the quality of the final product. The wire straightener is used to remove any bends or twists in the wire, ensuring that it remains straight and uniform throughout the drawing process. This not only improves the quality of the wire but also helps to prevent damage to the dies and other equipment.

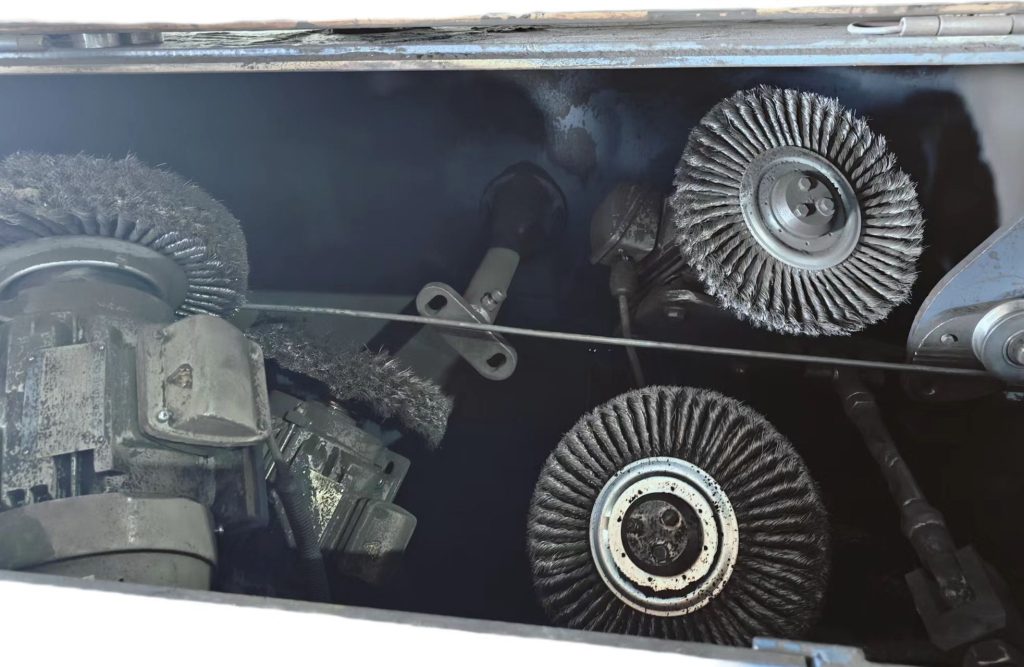

Another essential piece of Steel Brush Descaler for Wire Drawing Process is the lubrication system. As the wire is pulled through the dies, friction can build up, causing heat and wear on both the wire and the dies. A lubrication system is used to reduce friction and heat, allowing the wire to move more smoothly through the dies and reducing wear on the equipment. This not only improves the efficiency of the drawing process but also helps to extend the life of the dies and other components.

In addition to wire straighteners and lubrication systems, there are several other types of auxiliary equipment that are commonly used in wire drawing. These include spoolers, which are used to wind the drawn wire onto spools for storage and transportation, and tension control systems, which help to maintain a consistent tension on the wire as it is drawn through the dies. These auxiliary equipment pieces work together to ensure that the wire drawing process runs smoothly and efficiently, producing high-quality wire products.

The importance of auxiliary equipment in the wire drawing process cannot be overstated. Without these essential pieces of equipment, the quality of the wire products produced would be compromised, and the efficiency of the process would be greatly reduced. By investing in high-quality auxiliary equipment and ensuring that it is properly maintained and operated, manufacturers can improve the quality of their wire products, reduce downtime and maintenance costs, and increase overall productivity.

In conclusion, auxiliary equipment plays a crucial role in the wire drawing process, helping to ensure the efficiency and quality of the final product. Wire straighteners, lubrication systems, spoolers, and tension control systems are just a few examples of the essential auxiliary equipment used in wire drawing. By investing in high-quality auxiliary equipment and ensuring that it is properly maintained and operated, manufacturers can improve the quality of their wire products, reduce downtime and maintenance costs, and increase overall productivity.