Table of Contents

Common Maintenance Tips for Ensuring Longevity and Efficiency of Wire Drawing Machines

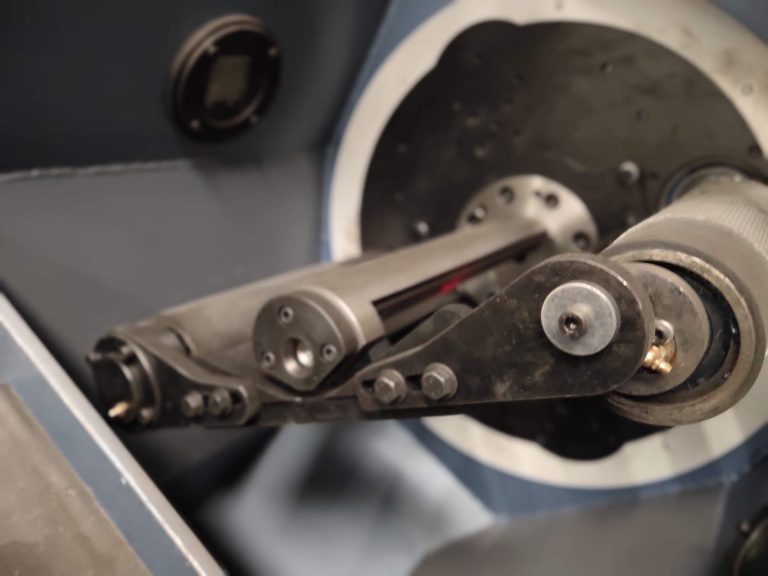

Wire drawing machines are essential tools in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. This process is crucial for producing wires of various sizes and shapes, which are used in a wide range of applications, from electrical wiring to construction materials. To ensure the longevity and efficiency of wire drawing machines, it is important to follow some common maintenance tips.

One of the most important maintenance tasks for wire drawing machines is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased efficiency and a shorter lifespan for the machine. To prevent this, it is important to clean the machine regularly, using a soft brush or cloth to remove any buildup. Additionally, lubricating the machine’s moving parts can help reduce friction and prolong its lifespan.

Another important maintenance tip for aluminum wire drawing machine is to inspect and replace worn or damaged parts. Over time, the dies, rollers, and other components of the machine can become worn or damaged, leading to decreased performance. Regularly inspecting these parts and replacing them when necessary can help ensure that the machine continues to operate efficiently. It is also important to follow the manufacturer’s recommendations for replacing parts, as using the wrong parts can cause further damage to the machine.

In addition to cleaning and replacing worn parts, it is important to regularly check the tension and alignment of the wire drawing machine. Improper tension or alignment can lead to uneven wire drawing, resulting in poor quality wire. By regularly checking and adjusting the tension and alignment of the machine, you can ensure that it continues to produce high-quality wire.

Regularly monitoring the machine’s performance is also important for ensuring its longevity and efficiency. By keeping track of factors such as speed, temperature, and power consumption, you can identify any issues early on and address them before they become more serious. This can help prevent costly repairs and downtime, ensuring that the machine continues to operate smoothly.

Finally, it is important to train operators on the proper use and maintenance of wire drawing machines. By providing training on how to operate the machine safely and effectively, you can help prevent accidents and damage to the machine. Additionally, educating operators on the importance of regular maintenance and inspection can help ensure that the machine remains in good working condition.

In conclusion, wire drawing machines are essential tools in the manufacturing industry, used for producing wires of various sizes and shapes. To ensure the longevity and efficiency of these machines, it is important to follow some common maintenance tips, such as regular cleaning, inspecting and replacing worn parts, checking tension and alignment, monitoring performance, and training operators. By following these tips, you can help prolong the lifespan of your wire drawing machine and ensure that it continues to operate efficiently for years to come.

How to Choose the Right Wire Drawing Machine for Your Specific Needs

Wire drawing machines are essential tools in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. This process is crucial for producing wires of various sizes and shapes, making wire drawing machines a vital component in industries such as automotive, construction, and electronics. Choosing the right wire drawing machine for your specific needs is crucial to ensure optimal performance and efficiency in your production process.

When selecting a wire drawing machine, there are several factors to consider to ensure that it meets your requirements. The first consideration is the type of material you will be working with. Different wire drawing machines are designed to handle specific materials, such as steel, copper, or aluminum. It is essential to choose a machine that is compatible with the material you will be using to achieve the desired results.

Another important factor to consider is the size and shape of the wire you need to produce. Wire drawing machines come in various configurations, including single or multi-die machines, depending on the desired output. If you need to produce wires of different sizes and shapes, a multi-die machine may be more suitable for your needs. Additionally, consider the speed and capacity of the machine to ensure that it can meet your production requirements.

The quality of the wire drawing machine is also a crucial factor to consider. Look for machines from reputable manufacturers with a proven track record of producing high-quality equipment. A well-built machine will not only provide consistent performance but also require less maintenance and repair, saving you time and money in the long run.

Consider the features and capabilities of the wire drawing machine to ensure that it meets your specific requirements. Some machines come with advanced features such as automatic lubrication systems, digital controls, and safety features to enhance efficiency and productivity. Evaluate your production needs and choose a machine that offers the right combination of features to meet your requirements.

Cost is another important consideration when choosing a wire drawing machine. While it is essential to invest in a high-quality machine, it is also important to consider your budget constraints. Compare prices from different manufacturers and suppliers to find a machine that offers the best value for your money. Keep in mind that a higher upfront cost for a quality machine may result in long-term savings through improved performance and durability.

When selecting a wire drawing machine, it is essential to consider the level of technical support and service provided by the manufacturer. Look for companies that offer comprehensive training, maintenance, and repair services to ensure that your machine operates smoothly and efficiently. A reliable manufacturer will also provide prompt assistance in case of any issues or technical difficulties.

In conclusion, choosing the right wire drawing machine for your specific needs is crucial to ensure optimal performance and efficiency in your production process. Consider factors such as material compatibility, wire size and shape, machine quality, features, cost, and technical support when selecting a machine. By carefully evaluating these factors and choosing a machine from a reputable manufacturer, you can ensure that your wire drawing machine meets your requirements and helps you achieve your production goals.