Table of Contents

How to Choose the Right Welding Wire Straightening and Cutting Machine for Your Needs

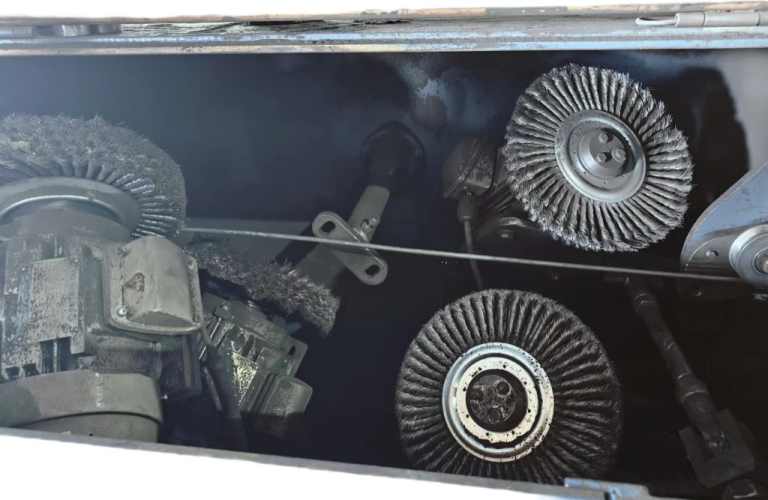

Welding Wire Straightening And Cutting Machines are essential tools for any welding operation. These machines help to ensure that welding wire is straightened and cut to the correct length, making the welding process more efficient and precise. However, with so many different options available on the market, it can be challenging to choose the right Welding Electrode Plant Wire Cutting Machines for your specific needs.

When selecting a welding wire straightening and cutting machine, there are several factors to consider. One of the most important factors to consider is the type of welding wire that you will be using. Different types of welding wire require different types of straightening and cutting machines. For example, if you will be using stainless steel welding wire, you will need a machine that is specifically designed to handle this type of wire.

Another important factor to consider is the diameter of the welding wire that you will be using. Different machines are designed to handle different diameters of welding wire, so it is essential to choose a machine that can accommodate the diameter of the wire that you will be working with.

In addition to the type and diameter of the welding wire, you should also consider the speed and accuracy of the machine. Some machines are capable of straightening and cutting welding wire at high speeds, while others are more suited for slower, more precise work. Depending on the volume of welding wire that you will be working with, you may need a machine that can handle high-speed production.

It is also essential to consider the size and weight of the machine. If you have limited space in your workshop, you will need to choose a machine that is compact and easy to move around. Additionally, if you will be transporting the machine to different job sites, you will need a machine that is lightweight and portable.

When choosing an Automatic Wire Straightening And Cutting Machines, it is also important to consider the quality and durability of the machine. You will want to choose a machine that is made from high-quality materials and is built to last. A durable machine will be able to withstand the rigors of daily use and will require less maintenance over time.

Finally, it is essential to consider the cost of the machine. Welding wire straightening and cutting machine can vary widely in price, so it is important to choose a machine that fits within your budget. However, it is essential to remember that quality should not be sacrificed for price. It is better to invest in a high-quality machine that will last for many years than to purchase a cheaper machine that will need to be replaced frequently.

In conclusion, choosing the right welding wire straightening and cutting machine for your needs requires careful consideration of several factors. By taking into account the type and diameter of the welding wire, the speed and accuracy of the machine, the size and weight of the machine, the quality and durability of the machine, and the cost of the machine, you can select a machine that will meet your specific needs and provide you with years of reliable service.

Benefits of Using a Welding Wire Straightening and Cutting Machine

Welding wire straightening and cutting machines are essential tools in the welding industry. These machines are designed to straighten and cut welding wire quickly and accurately, saving time and improving efficiency in the welding process. There are several benefits to using a welding wire straightening and cutting machine, including increased productivity, improved accuracy, and reduced waste.

One of the main benefits of using a welding wire straightening and cutting machine is increased productivity. These machines are capable of straightening and cutting wire at a much faster rate than manual methods, allowing welders to work more efficiently and complete projects in less time. This increased productivity can lead to higher output and greater profitability for welding businesses.

In addition to increased productivity, welding wire straightening and cutting machines also offer improved accuracy. These machines are designed to straighten and cut wire with precision, ensuring that each piece is the correct length and free of defects. This level of accuracy is essential in welding applications, where even small errors can lead to costly mistakes. By using a welding wire straightening and cutting machine, welders can ensure that their work meets the highest standards of quality.

Another benefit of using a welding wire straightening and cutting machine is reduced waste. When wire is straightened and cut manually, there is a greater risk of errors that can result in wasted material. This not only increases costs but also creates unnecessary waste that can harm the environment. By using a welding wire straightening and cutting machine, welders can minimize waste and maximize the use of materials, leading to a more sustainable and cost-effective welding process.

Furthermore, welding wire straightening and cutting machines are easy to use and require minimal training to operate. This makes them accessible to welders of all skill levels, allowing even novice welders to benefit from the increased productivity and accuracy that these machines offer. Additionally, many welding wire straightening and cutting machines are compact and portable, making them easy to transport to different job sites and use in a variety of welding applications.

Overall, the benefits of using a welding wire straightening and cutting machine are clear. These machines offer increased productivity, improved accuracy, reduced waste, and ease of use, making them essential tools for welders in the modern welding industry. By investing in a welding wire straightening and cutting machine, welders can streamline their workflow, improve the quality of their work, and achieve greater success in their welding projects.