Table of Contents

Benefits of Using a High Speed Copper Coating Line for CO2 Welding Wire

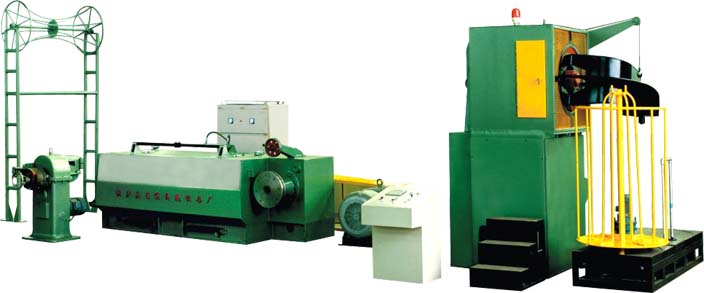

A High Speed Copper Coating Production Line For CO2 Welding Wire Line offers numerous benefits to manufacturers in the welding industry. This advanced technology allows for faster and more efficient production of welding wire, resulting in cost savings and improved product quality.

One of the key advantages of using a high-speed copper coating line is the increased production speed. By automating the process of applying copper coating to the welding wire, manufacturers can significantly reduce the time it takes to produce a finished product. This not only allows for higher output levels but also enables manufacturers to meet tight production deadlines and customer demands.

In addition to speed, a high-speed copper coating line also offers improved consistency and quality control. The automated nature of the equipment ensures that each wire is coated with the exact amount of copper required, resulting in uniformity across the entire production run. This consistency is essential for ensuring the quality and performance of the welding wire, as any variations in coating thickness can affect the wire’s conductivity and weldability.

Furthermore, the use of a high-speed copper coating line can help manufacturers reduce waste and improve efficiency in their production process. By precisely controlling the amount of copper applied to each wire, manufacturers can minimize material waste and reduce the need for rework or scrap. This not only saves on raw material costs but also reduces the environmental impact of the manufacturing process.

Another benefit of using a high-speed copper coating line is the improved safety and working conditions for employees. By automating the coating process, manufacturers can reduce the need for manual handling of the welding wire, which can be a hazardous task. This helps to create a safer work environment and reduce the risk of injuries or accidents on the production floor.

Additionally, the use of a high-speed copper coating line can help manufacturers enhance their overall competitiveness in the market. By increasing production speed and efficiency, manufacturers can reduce their production costs and offer more competitive pricing to customers. This can help to attract new business and retain existing customers, ultimately leading to increased profitability and growth for the company.

Overall, the benefits of using a high-speed copper coating line for CO2 welding wire are clear. From increased production speed and efficiency to improved quality control and safety, this advanced technology offers numerous advantages to manufacturers in the welding industry. By investing in a high-speed copper coating line, manufacturers can position themselves for success in a competitive market and drive continued growth and innovation in their operations.

How to Choose the Right High Speed Copper Coating Line for CO2 Welding Wire Production

When it comes to CO2 welding wire production, having the right equipment is essential for ensuring high-quality results. One key piece of equipment that is crucial for this process is a high-speed copper coating line. This machine is responsible for applying a thin layer of copper to the surface of the welding wire, which helps to improve its conductivity and overall performance.

Choosing the right High Speed Copper-Coating Line For CO2 Welding Wire production can be a daunting task, as there are many factors to consider. In this article, we will discuss some key considerations to keep in mind when selecting a copper coating line for your operation.

First and foremost, it is important to consider the speed and capacity of the copper coating line. High-speed lines are capable of coating large volumes of wire in a short amount of time, which can help to increase productivity and efficiency in your operation. Additionally, you will want to ensure that the line has the capacity to handle the volume of wire that you will be producing on a regular basis.

Another important factor to consider is the quality of the coating that the line is capable of producing. A high-quality copper coating is essential for ensuring that the welding wire performs as expected and meets industry standards. Look for a coating line that is capable of producing a consistent and uniform coating on each wire, as this will help to minimize defects and ensure the overall quality of your product.

In addition to speed and quality, it is also important to consider the overall reliability and durability of the copper coating line. Look for a machine that is built to last and can withstand the rigors of daily use in a production environment. A reliable machine will help to minimize downtime and maintenance costs, ensuring that your operation runs smoothly and efficiently.

When selecting a high-speed copper coating line, it is also important to consider the level of automation and control that the machine offers. Automated features can help to streamline the production process and reduce the need for manual intervention, while advanced control systems can help to ensure that the coating process is consistent and repeatable.

Finally, it is important to consider the overall cost of the copper coating line, including both the initial investment and ongoing operating costs. While it may be tempting to opt for a lower-cost machine, it is important to consider the long-term implications of this decision. Investing in a high-quality, reliable machine may cost more upfront, but it can help to save money in the long run by reducing maintenance costs and downtime.

In conclusion, choosing the right high-speed copper coating line for your CO2 welding wire production is essential for ensuring high-quality results and maximizing efficiency in your operation. By considering factors such as speed, quality, reliability, automation, and cost, you can select a machine that meets your specific needs and helps to drive success in your business.