Advanteges of Implementing a High Speed Copper Coating Production Line for CO2 Welding Wire Production

In the world of manufacturing, efficiency and productivity are key factors in ensuring success. One area where these factors are particularly important is in the production of CO2 welding wire. CO2 welding wire is a crucial component in the welding industry, used in a variety of applications from automotive to construction. To meet the growing demand for this essential product, manufacturers are constantly looking for ways to improve their production processes. One solution that has proven to be highly effective is the implementation of a High Speed Copper-Coating Line For CO2 Welding Wire production.

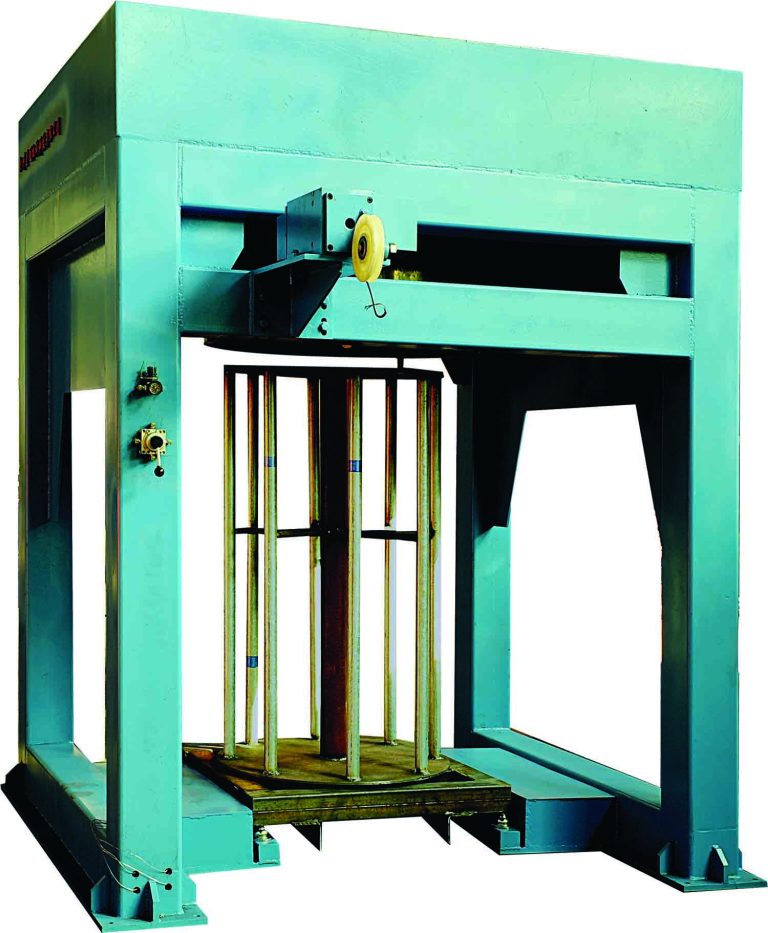

By investing in a high-speed copper coating production line, manufacturers can significantly increase their production capacity and efficiency. These production lines are designed to coat welding wire with a thin layer of copper at high speeds, allowing for faster and more consistent production. This not only speeds up the manufacturing process but also ensures a higher quality product that meets industry standards.

One of the key benefits of implementing a high-speed copper coating production line is the increase in production capacity. These production lines are capable of coating welding wire at speeds of up to 200 meters per minute, significantly faster than traditional coating methods. This allows manufacturers to produce larger quantities of welding wire in a shorter amount of time, meeting the demands of their customers more efficiently.

In addition to increased production capacity, high-speed copper coating production lines also offer improved quality control. The automated nature of these production lines ensures that each piece of welding wire is coated consistently and accurately, reducing the risk of defects or inconsistencies in the final product. This results in a higher quality welding wire that meets industry standards and customer expectations.

Furthermore, high-speed copper coating production lines are also more cost-effective in the long run. While the initial investment in a new production line may be significant, the increased production capacity and efficiency that it provides can lead to significant cost savings over time. By producing more welding wire in less time, manufacturers can reduce their production costs and increase their profit margins.

Another benefit of implementing a high-speed copper coating production line is the reduction in labor costs. These production lines are highly automated, requiring minimal human intervention to operate. This not only reduces the need for manual labor but also eliminates the risk of human error in the production process. This allows manufacturers to reallocate their workforce to other areas of the production process, further increasing efficiency and productivity.

Overall, the implementation of a high-speed copper coating production line for CO2 welding wire production offers a wide range of benefits for manufacturers. From increased production capacity and efficiency to improved quality control and cost savings, these production lines are a valuable investment for any welding wire manufacturer looking to stay competitive in the industry. By embracing new technologies and automation, manufacturers can streamline their production processes and meet the growing demands of their customers with ease.