Exploring the Benefits of Using Dead Block Coiler for Drawing Machines

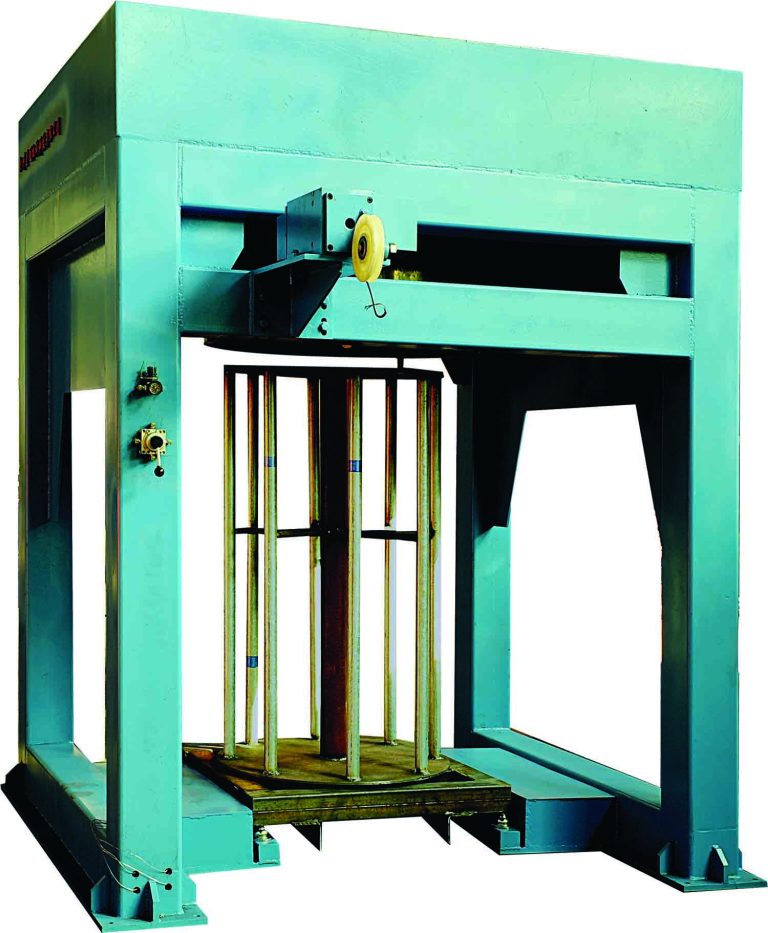

Dead block coilers are an essential component in drawing machines, used in the wire and cable industry for the production of various types of wires. These coilers play a crucial role in the manufacturing process by providing tension control and ensuring the smooth winding of the wire onto the spool. One type of coiler that is commonly used in drawing machines is the dead block coiler, which offers several benefits over other types of coilers.

One of the main advantages of using a dead block coiler is its ability to provide precise tension control during the winding process. This is crucial in ensuring that the wire is wound evenly onto the spool, without any slack or tension issues. The dead block coiler achieves this by using a pneumatic or hydraulic system to apply the necessary tension to the wire as it is being wound. This results in a high-quality finished product with consistent winding tension throughout the spool.

Another benefit of using a dead block coiler is its ability to handle a wide range of wire sizes and materials. Drawing machines are used to produce wires of various diameters and materials, and the dead block coiler can easily accommodate these different requirements. This versatility makes the dead block coiler a cost-effective solution for manufacturers who need to produce a variety of wire products.

In addition to its versatility, the dead block coiler is also known for its reliability and durability. These coilers are built to withstand the rigors of continuous operation in a manufacturing environment, ensuring that they can handle the demands of high-volume production. This reliability is essential for manufacturers who rely on their drawing machines to produce consistent and high-quality wire products.

Furthermore,Static Coiler With Horizontal Capstan are easy to maintain and operate, making them a practical choice for manufacturers looking to streamline their production processes. These coilers are designed with user-friendly controls and features that make them easy to set up and adjust for different wire sizes and materials. Additionally, their simple design means that they require minimal maintenance, reducing downtime and ensuring that production can continue uninterrupted.

Overall, the benefits of using a dead block coiler for drawing machines are clear. From precise tension control to versatility and reliability, these coilers offer a range of advantages that make them an essential component in the wire and cable manufacturing industry. Manufacturers looking to improve the efficiency and quality of their production processes should consider incorporating dead block coilers into their drawing machines.

In conclusion, dead block coilers are a valuable tool for manufacturers in the wire and cable industry. Their ability to provide precise tension control, handle a wide range of wire sizes and materials, and offer reliability and ease of operation make them an ideal choice for drawing machines. By investing in dead block coilers, manufacturers can improve the efficiency and quality of their production processes, ultimately leading to better products and increased profitability.