Table of Contents

Maintenance Tips for Keeping Your Wire ReWinding Machine in Top Condition

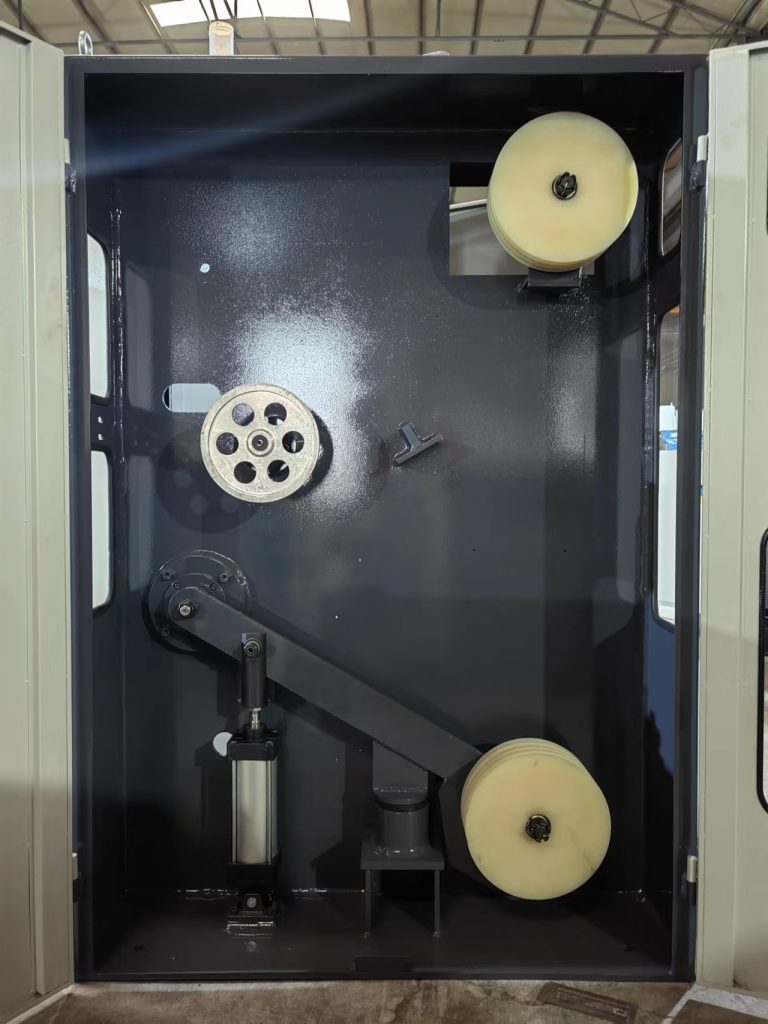

Wire rewinding machines are essential tools in various industries for efficiently rewinding wire coils. To ensure that your wire rewinding machine operates at its best, regular maintenance is crucial. By following these maintenance tips, you can keep your wire rewinding machine in top condition and prolong its lifespan.

First and foremost, it is important to regularly clean your wire rewinding machine. Dust, dirt, and debris can accumulate on the machine over time, leading to decreased performance and potential damage. Use a soft brush or cloth to gently remove any buildup on the machine’s surfaces, including the wire guides, tensioners, and spindles. Be sure to also clean the wire cutting blades to prevent them from becoming dull and ineffective.

In addition to cleaning, lubricating the moving parts of your wire rewinding machine is essential for smooth operation. Apply a small amount of lubricant to the bearings, gears, and other moving components to reduce friction and wear. Be sure to use the appropriate type of lubricant recommended by the manufacturer to avoid damaging the machine.

Regularly inspecting the wire rewinding machine for any signs of wear or damage is another important maintenance tip. Check for loose or missing screws, worn-out parts, and any unusual noises or vibrations during operation. Addressing these issues promptly can prevent further damage and ensure that the machine continues to function properly.

Calibrating the tension settings on your wire rewinding machine is also crucial for optimal performance. Improper tension can lead to wire breakage, uneven winding, and other issues. Use a tension gauge to check and adjust the tension settings as needed, following the manufacturer’s guidelines for the specific type of wire being used.

Another important maintenance tip for keeping your wire rewinding machine in top condition is to regularly check and replace worn-out or damaged parts. Over time, components such as wire guides, tensioners, and cutting blades can become worn and less effective. Replace these parts as needed to ensure that the machine operates efficiently and produces high-quality rewound wire coils.

Lastly, scheduling regular professional maintenance and servicing for your wire rewinding machine is essential for its long-term performance. A trained technician can inspect the machine thoroughly, identify any potential issues, and perform necessary repairs or adjustments. Regular servicing can help prevent costly breakdowns and downtime, keeping your production running smoothly.

In conclusion, proper maintenance is key to keeping your wire rewinding machine in top condition. By following these maintenance tips, you can ensure that your machine operates efficiently, produces high-quality rewound wire coils, and lasts for years to come. Remember to clean, lubricate, inspect, calibrate, replace worn-out parts, and schedule regular professional servicing to keep your wire rewinding machine in optimal working condition.

Benefits of Using a Wire Rewinding Machine

A wire rewinding machine is a valuable tool that is used in various industries to efficiently wind wire onto spools or reels. This machine offers a wide range of benefits that can help improve productivity and streamline operations. In this article, we will explore some of the key advantages of using a wire rewinding machine.

One of the primary benefits of using a wire rewinding machine is its ability to increase efficiency. Manual wire winding can be a time-consuming and labor-intensive process, especially when dealing with large quantities of wire. A wire rewinding machine automates this process, allowing for faster and more consistent winding of wire onto spools. This can help save time and labor costs, ultimately improving overall productivity.

Additionally, a wire rewinding machine can help improve the quality of the wound wire. Manual winding can result in uneven winding tension, which can lead to issues such as wire breakage or tangling. A wire rewinding machine ensures that the wire is wound evenly and with consistent tension, resulting in a higher-quality end product. This can help reduce waste and improve the overall reliability of the wire.

Another benefit of using a wire rewinding machine is its versatility. These machines can be customized to accommodate a wide range of wire sizes and types, making them suitable for a variety of applications. Whether you are working with thin gauge wire or thick cable, a wire rewinding machine can be tailored to meet your specific needs. This flexibility allows for greater adaptability in different production environments.

In addition to efficiency and quality improvements, a wire rewinding machine can also help enhance workplace safety. Manual wire winding can pose risks to workers, especially when dealing with heavy or sharp wire. By automating the winding process, a wire rewinding machine can help reduce the risk of injuries and create a safer working environment for employees. This can lead to fewer accidents and improved overall employee morale.

Furthermore, using a wire rewinding machine can help reduce material waste. Manual winding can result in excess wire being used or wasted due to uneven winding or errors in the winding process. A wire rewinding machine ensures that the wire is wound accurately and efficiently, minimizing waste and reducing costs. This can lead to significant savings over time, making the investment in a wire rewinding machine a cost-effective choice for many businesses.

Overall, the benefits of using a wire rewinding machine are clear. From increased efficiency and improved quality to enhanced workplace safety and reduced waste, these machines offer a wide range of advantages for businesses in various industries. By investing in a wire rewinding machine, companies can streamline their operations, improve productivity, and ultimately achieve greater success in their wire winding processes.

How to Choose the Right Wire Rewinding Machine for Your Needs

Wire rewinding machines are essential tools for businesses that deal with large quantities of wire on a regular basis. These machines are designed to efficiently wind wire onto spools or reels, making it easier to transport and store. However, with so many different options available on the market, choosing the right wire rewinding machine for your specific needs can be a daunting task. In this article, we will discuss some key factors to consider when selecting a wire rewinding machine to ensure that you make the best choice for your business.

One of the first things to consider when choosing a wire rewinding machine is the type of wire you will be working with. Different machines are designed to handle different types of wire, so it is important to choose a machine that is compatible with the wire you will be using. For example, if you will be working with thin, delicate wire, you will need a machine that is designed to handle this type of wire without causing damage.

Another important factor to consider is the speed and capacity of the machine. If you will be working with large quantities of wire on a regular basis, you will need a machine that can handle high speeds and large capacities. On the other hand, if you will only be rewinding small amounts of wire occasionally, a smaller, slower machine may be sufficient for your needs.

It is also important to consider the size and weight of the machine. If you have limited space in your workspace, you will need to choose a machine that is compact and easy to move around. Additionally, if you will be transporting the machine to different locations, you will need to choose a machine that is lightweight and portable.

When choosing a wire rewinding machine, it is also important to consider the level of automation that you require. Some machines are fully automated, meaning that they can operate without any human intervention. Other machines require manual operation, which may be more suitable for businesses with specific requirements or preferences.

In addition to these factors, it is also important to consider the reputation of the manufacturer when choosing a wire rewinding machine. Look for a manufacturer that has a good track record of producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can also help you make an informed decision.

In conclusion, choosing the right wire rewinding machine for your needs requires careful consideration of several key factors. By taking into account the type of wire you will be working with, the speed and capacity of the machine, the size and weight of the machine, the level of automation required, and the reputation of the manufacturer, you can ensure that you make the best choice for your business. Investing in a high-quality wire rewinding machine will not only improve the efficiency of your operations but also save you time and money in the long run.