Understanding Of Using Reversed Bending Descaling Machine In Industrial Applications

In industrial applications, the process of Wire Rod Descaling Machine is crucial for maintaining the efficiency and longevity of equipment. Descaling involves removing scale, rust, and other impurities from metal surfaces to prevent corrosion and improve performance. One effective method for descaling is the use of a reversed bending descaling machine.

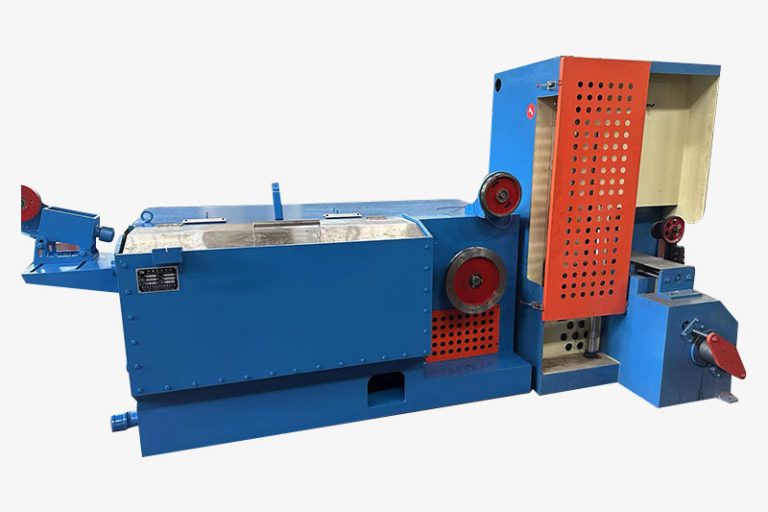

The reversed bending descaling machine is a specialized piece of equipment designed to efficiently and effectively remove scale from metal surfaces. This machine uses a series of rollers and brushes to bend the metal in the opposite direction, causing the scale to crack and break off. The result is a clean, smooth surface that is free from impurities.

One of the key benefits of using a Reversed Bending Descaler For Wire Drawing Prepration Process is its ability to save time and labor. Traditional descaling methods often require manual labor and can be time-consuming. With a reversed bending descaling machine, the process is automated, allowing for faster and more efficient descaling. This not only saves time but also reduces the risk of human error, resulting in a more consistent and reliable outcome.

Another benefit of using a reversed bending descaling machine is its versatility. This machine can be used on a wide range of metal surfaces, including steel, aluminum, and copper. Whether descaling pipes, sheets, or other metal components, the reversed bending descaling machine can effectively remove scale and improve surface quality.

In addition to saving time and labor, the reversed bending descaling machine also helps to improve the overall quality of the metal surface. By removing scale and impurities, the machine creates a clean, smooth surface that is ready for further processing or finishing. This results in a higher-quality end product that meets industry standards and customer expectations.

Furthermore, using a reversed bending descaling machine can help to extend the lifespan of equipment and reduce maintenance costs. Scale and rust can cause corrosion and wear on metal surfaces, leading to premature failure and costly repairs. By regularly descaling metal surfaces with a reversed bending descaling machine, companies can prevent corrosion and prolong the life of their equipment, saving money in the long run.

Overall, the benefits of using a in industrial applications are clear. From saving time and labor to improving surface quality and extending equipment lifespan, this specialized piece of equipment offers numerous advantages for companies looking to maintain the efficiency and reliability of their operations. By investing in a reversed bending descaling machine, companies can ensure that their metal surfaces are clean, smooth, and free from impurities, leading to better performance and increased productivity.