Table of Contents

The History and Evolution of Carrie Block in Enkotec Nail Making Machine Technology

Carrie Block has played a significant role in the history and evolution of Enkotec nail making machine technology. The company has been at the forefront of innovation in the nail making industry for decades, constantly pushing the boundaries of what is possible with their cutting-edge technology. In this article, we will explore the history of Carrie Block and how they have helped shape the Enkotec nail making machine into what it is today.

Carrie Block was founded in the early 20th century and quickly established itself as a leader in the nail making industry. The company’s commitment to quality and innovation set them apart from their competitors, and they soon became known for their reliable and efficient nail making machines. As technology advanced, Carrie Block was quick to adapt and incorporate new advancements into their machines, ensuring that they remained at the forefront of the industry.

One of the key innovations that Carrie Block introduced to the Enkotec nail making machine was the use of computerized controls. This allowed for greater precision and accuracy in the manufacturing process, resulting in nails that were of higher quality and consistency. The use of computerized controls also made the machines easier to operate, reducing the need for skilled labor and increasing productivity.

Another important development in the history of Carrie Block and the Enkotec nail making machine was the introduction of automatic feeding systems. This innovation allowed for a continuous supply of materials to the machine, eliminating the need for manual intervention and further increasing efficiency. The automatic feeding systems also helped to reduce waste and improve overall product quality.

In addition to these technological advancements, Carrie Block has also focused on sustainability and environmental responsibility in their nail making machines. The company has implemented energy-efficient designs and processes, as well as recycling programs to minimize waste and reduce their carbon footprint. By prioritizing sustainability, Carrie Block has not only helped to protect the environment but has also improved the overall efficiency and cost-effectiveness of their machines.

As the nail making industry continues to evolve, Carrie Block remains committed to innovation and excellence in their Enkotec nail making machines. The company continues to invest in research and development, exploring new technologies and techniques to further improve their machines’ performance and capabilities. By staying ahead of the curve, Carrie Block ensures that their machines remain the top choice for nail manufacturers around the world.

In conclusion, Carrie Block has played a crucial role in the history and evolution of Enkotec nail making machine technology. Through their commitment to quality, innovation, and sustainability, the company has helped to shape the nail making industry and set the standard for excellence in nail manufacturing. As technology continues to advance, Carrie Block will undoubtedly continue to lead the way, pushing the boundaries of what is possible with their state-of-the-art Enkotec nail making machines.

How Carrie Block Enhances Efficiency and Precision in Enkotec Nail Making Machine Operations

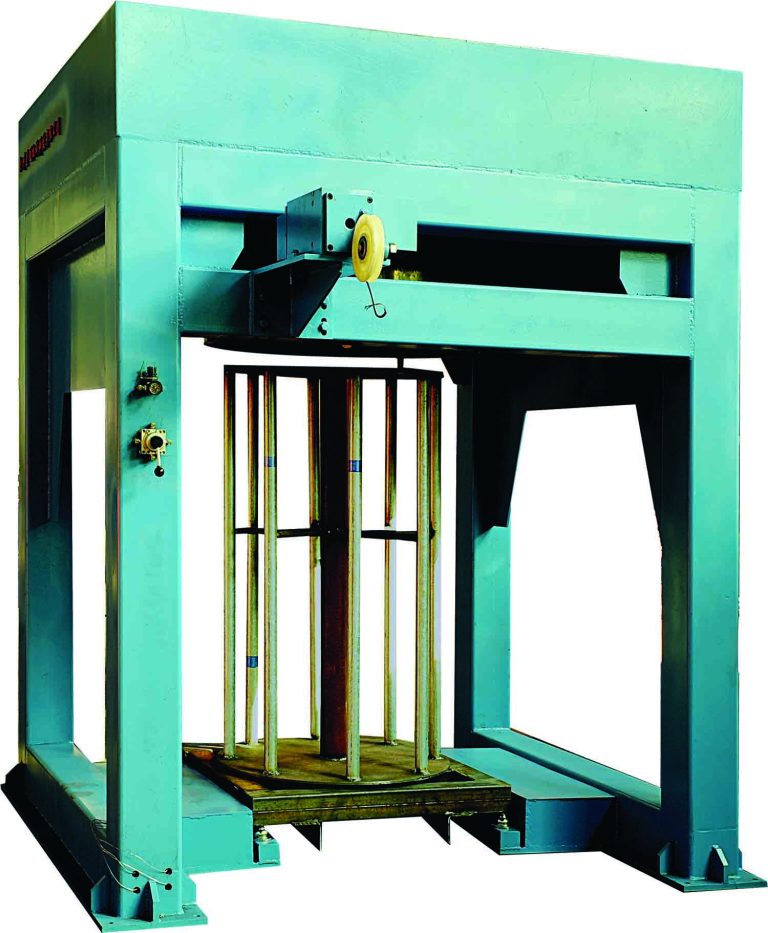

Carrie Block is a crucial component in the Enkotec nail making machine that plays a significant role in enhancing efficiency and precision in nail production operations. This innovative technology has revolutionized the nail manufacturing industry by streamlining the production process and ensuring consistent quality output.

One of the key benefits of Carrie Block is its ability to automate the feeding and cutting of wire, eliminating the need for manual intervention and reducing the risk of human error. This automation not only speeds up the production process but also ensures that each nail is cut to the exact specifications, resulting in uniformity and precision in the final product.

Furthermore, Carrie Block is equipped with advanced sensors and monitoring systems that constantly monitor the production process and make real-time adjustments to optimize performance. This level of automation and control not only improves efficiency but also minimizes waste and reduces downtime, ultimately leading to cost savings for nail manufacturers.

In addition to its automation capabilities, Carrie Block is also designed to be user-friendly and easy to operate. Its intuitive interface allows operators to quickly set up the machine, monitor production progress, and troubleshoot any issues that may arise. This ease of use not only reduces training time for operators but also ensures that the machine can be operated efficiently and effectively by personnel of varying skill levels.

Another key advantage of Carrie Block is its versatility and adaptability to different nail sizes and types. The machine can be easily reconfigured to produce various nail sizes and styles, allowing manufacturers to quickly switch between production runs without significant downtime. This flexibility is essential for nail manufacturers who need to respond quickly to changing market demands and customer preferences.

Moreover, Carrie Block is built to withstand the rigors of continuous operation in a manufacturing environment. Its robust construction and high-quality components ensure long-term reliability and durability, minimizing maintenance requirements and maximizing uptime. This reliability is essential for nail manufacturers who rely on their equipment to deliver consistent performance day in and day out.

Overall, Carrie Block is a game-changer for nail manufacturers looking to improve efficiency and precision in their production operations. Its automation, monitoring capabilities, user-friendly interface, versatility, and reliability make it an indispensable tool for streamlining nail production processes and ensuring consistent quality output. By investing in Carrie Block technology, nail manufacturers can stay ahead of the competition, meet customer demands, and drive profitability in their operations.