Izinto eziluncedo zokusebenzisa i-A Umatshini wokuzoba ngocingo lohlobo olumanzi kwiFactory

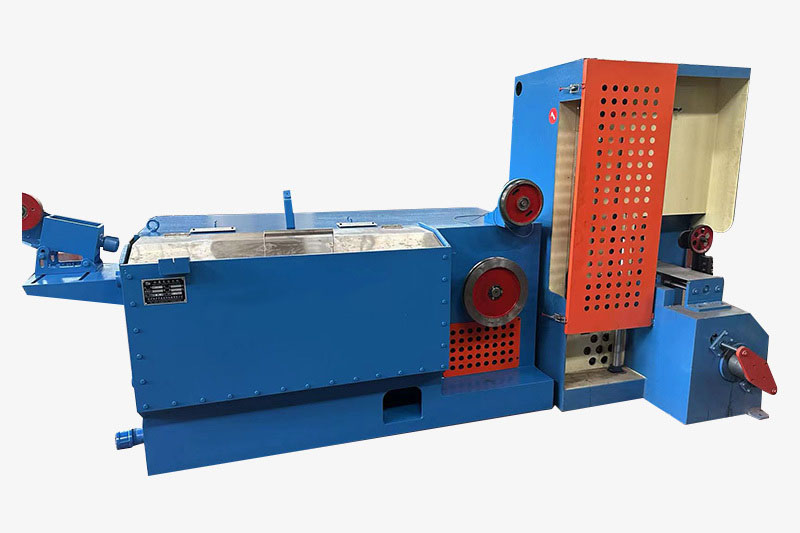

Umatshini wokuzoba ngocingo olumanzi sisixhobo esibalulekileyo kushishino lokwenziwa kweengcingo. Lo matshini usetyenziselwa ukunciphisa i-diameter yocingo ngokuyitsala ngothotho lwee-dies, okukhokelela kucingo olugudileyo nolufanayo. Kukho iingenelo ezininzi zokusebenzisa umatshini wokudweba ucingo olumanzi, esiza kuhlola kweli nqaku.

Enye yeenzuzo eziphambili zokusebenzisa umatshini wokudweba ucingo olumanzi ngumgangatho ophuculweyo wocingo oluveliswayo. I-lubrication ebonelelwa ngamanzi okanye i-oyile yokuhlamba kumatshini inceda ukunciphisa ingxabano phakathi kocingo kunye nokufa, okukhokelela ekugqityweni komphezulu ogudileyo.Ukongezelela ekuphuculeni umgangatho wocingo, a umatshini wokuzoba ngocingo olumanziEkuqukunjelweni, umatshini wokudweba ucingo olumanzi unikezela ngeenzuzo ezininzi kumatshini wokudweba owomileyo, kubandakanywa nomgangatho wocingo ophuculweyo, ukunyuka kwemveliso, ukukwazi ukudweba ama-diameters amancinci, ubungane bendalo, kunye nokuguquguquka. Ezi zibonelelo zenza ukuba ibe sisixhobo esibalulekileyo kwishishini lokuvelisa ucingo, inceda ukuvelisa ucingo olukumgangatho ophezulu ngokufanelekileyo nangempumelelo.

Another advantage of using a Wet Type Wire Drawing Machine is the ability to draw wire to smaller diameters. The lubrication provided by the water or oil bath helps to reduce the force required to pull the wire through the dies, allowing for greater reductions in diameter. This is particularly useful in industries that require fine wire for applications such as electronics or medical devices.

Furthermore, a wet type wire drawing machine is more environmentally friendly than dry drawing machines. The use of water or oil as a lubricant reduces the amount of friction and heat generated during the drawing process, resulting in lower energy consumption. Additionally, the lubricant can be recycled and reused, further reducing waste and environmental impact.

One of the key advantages of using a wet type wire drawing machine is the versatility it offers in terms of the types of wire that can be produced. This machine can handle a wide range of materials, including steel, copper, aluminum, and other alloys. It can also produce wire in various shapes and sizes, making it suitable for a wide range of applications.

In conclusion, a wet type wire drawing machine offers several advantages over dry drawing machines, including improved wire quality, increased productivity, the ability to draw smaller diameters, environmental friendliness, and versatility. These advantages make it an essential piece of equipment in the wire manufacturing industry, helping to produce high-quality wire efficiently and effectively.