Table of Contents

Izinto eziLungileyo zokuSebenzisa oomatshini bokuzoba boNxibelelwano oluManzi kwiiNcingo zeKopolo

IiNgcebiso zokuLondoloza kuMshini woMzobo weNxibelelwano oluManzi kwiNcingo yeCopper

Okokuqala kwaye kubaluleke kakhulu, kubalulekile ukuhlola rhoqo umatshini ukuba kukho naziphi na iimpawu zokugqoka kunye nokukrazula. Jonga ii-dies, rollers, kunye namanye amacandelo awo nawuphi na umonakalo okanye ukunxiba okugqithisileyo. Shintshanisa naziphi na iindawo ezigugileyo okanye ezonakeleyo ngoko nangoko ukuze kuthintelwe umonakalo ongakumbi kumatshini kwaye uqinisekise ukusebenza kakuhle.

Ukucocwa komatshini rhoqo nako kubalulekile ekugcinweni kwawo. Susa nayiphi na inkunkuma, i-debris, okanye i-lubricant buildup kumatshini ukukhusela ukuvala kunye nokuqinisekisa ukuthambisa okufanelekileyo. Sebenzisa i-detergent epholileyo kunye namanzi ukucoca umatshini, uqaphele ukuba ungasebenzisi iikhemikhali ezinobunzima ezinokulimaza amacandelo.

Ukuthambisa rhoqo umatshini kubalulekile ukunciphisa ukungqubuzana nokushisa ngexesha lokuzoba. Sebenzisa i-lubricant yamanzi ekhuthazwa ngumenzi ukuqinisekisa ukusebenza kakuhle kunye nokuthintela umonakalo kumatshini. Faka i-lubricant kwi-dies, rollers, kunye nezinye iindawo ezihambayo rhoqo ukuqinisekisa ukusebenza kakuhle.

Hlola inkqubo yokupholisa yomatshini rhoqo ukuqinisekisa ukusebenza ngokufanelekileyo. Inkqubo yokupholisa inceda ukutshabalalisa ukushisa okwenziwa ngexesha lokudweba kunye nokukhusela ukufudumala komatshini. Jonga amanqanaba okupholisa, imibhobho, kunye neempompo rhoqo ukuqinisekisa ukuba zisebenza kakuhle. Faka endaweni yazo naziphi na izinto ezigugileyo okanye ezonakalisiweyo ukunqanda ukutshisa kakhulu kwaye uqinisekise ixesha elide lomatshini.

Hlala ujonge ukuxinana kocingo ngexesha lokuzoba. Uxinzelelo olufanelekileyo lubalulekile ekuphumezeni ubukhulu obunqwenelekayo bocingo kunye nokuthintela ukwaphuka. Lungisa ukuxinana njengoko kufuneka ukuqinisekisa ukusebenza kakuhle kunye nokuveliswa kweengcingo ezikumgangatho ophezulu.

Okokugqibela, kubalulekile ukuqeqesha abaqhubi ekusebenziseni ngokufanelekileyo kunye nokugcinwa komatshini wokudweba ucingo olumanzi. Uqeqesho olufanelekileyo lunokunceda ukuthintela iimpazamo zabaqhubi ezinokukhokelela kumonakalo womatshini kunye nexesha lokuphumla. Qinisekisa ukuba abaqhubi baqhelene nokusebenza komatshini, iinkqubo zokulondoloza, kunye nezilumkiso zokhuseleko ukuze kuqinisekiswe ukusebenza kakuhle kunye nexesha elide lomatshini.

Ekuqukumbeleni, ukugcinwa rhoqo komatshini wokudweba ucingo olumanzi ngocingo lobhedu kubalulekile ukuze kuqinisekiswe ukusebenza kwawo ngokugqibeleleyo kwaye ubomi obude. Ngokulandela ezi ngcebiso zokugcina, unokuthintela ukuqhekeka, ukunciphisa ixesha lokuphumla, kunye nokwandisa ubomi bomatshini. Ukugcinwa okufanelekileyo kunokukunceda ufezekise umgangatho ophezulu wemveliso yocingo kunye nokwandisa ukusebenza kakuhle kwemisebenzi yakho

Maintenance Tips for Wet Type Wire Drawing Machine for Copper Wire

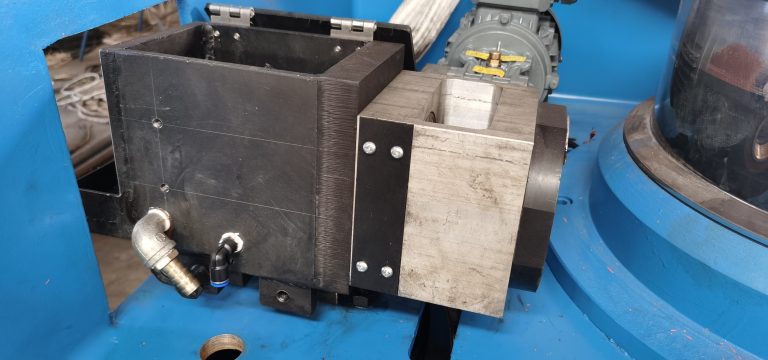

A wet type wire drawing machine is a crucial piece of equipment in the production of copper wire. This machine is used to reduce the diameter of copper wire by pulling it through a series of dies. The wet type wire drawing machine is called so because it uses a lubricant, typically water-based, to reduce friction and heat during the drawing process. This lubricant helps to improve the quality of the wire and prolong the life of the dies.

Maintenance of a wet wire drawing machine is essential to ensure its optimal performance and longevity. Regular maintenance can help prevent breakdowns, reduce downtime, and extend the lifespan of the machine. Here are some maintenance tips for a wet type wire drawing machine for copper wire.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check the dies, rollers, and other components for any damage or excessive wear. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure smooth operation.

Cleaning the machine regularly is also crucial for its maintenance. Remove any dirt, debris, or lubricant buildup from the machine to prevent clogging and ensure proper lubrication. Use a mild detergent and water to clean the machine, taking care not to use harsh chemicals that could damage the components.

Regularly lubricating the machine is essential to reduce friction and heat during the drawing process. Use a water-based lubricant recommended by the manufacturer to ensure optimal performance and prevent damage to the machine. Apply the lubricant to the dies, rollers, and other moving parts regularly to ensure smooth operation.

Inspect the cooling system of the machine regularly to ensure proper functioning. The cooling system helps to dissipate heat generated during the drawing process and prevent overheating of the machine. Check the coolant levels, hoses, and pumps regularly to ensure they are functioning properly. Replace any worn or damaged components to prevent overheating and ensure the longevity of the machine.

Regularly check the tension of the wire during the drawing process. Proper tension is crucial for achieving the desired diameter of the wire and preventing breakage. Adjust the tension as needed to ensure smooth operation and high-quality wire production.

Lastly, it is important to train operators on the proper use and maintenance of the wet type wire drawing machine. Proper training can help prevent operator errors that could lead to machine damage and downtime. Ensure operators are familiar with the machine’s operation, maintenance procedures, and safety precautions to ensure optimal performance and longevity of the machine.

In conclusion, regular maintenance of a wet type wire drawing machine for copper wire is essential to ensure its optimal performance and longevity. By following these maintenance tips, you can prevent breakdowns, reduce downtime, and extend the lifespan of the machine. Proper maintenance can help you achieve high-quality wire production and maximize the efficiency of your operations.