Table of Contents

Iingcebiso zoLondolozo loMshini woMzobo woNxibelelwano olumanzi lweAluminiyam yocingo

Ukuthelekiswa kohlobo olumanzi vs uhlobo olomileyo lomatshini wokuzoba ngocingo lweAluminiyam

IiNzuzo zokuSebenzisa umatshini wokuzoba woNxibelelwano olumanzi lweAluminiyam yocingo

Enye yeenzuzo eziphambili zokusebenzisa umatshini wokudweba ucingo olumanzi kwi-aluminium yocingo kukuba inceda ukuphucula ukugqitywa komphezulu wocingo. Inkqubo yokudweba emanzi ibandakanya ukusebenzisa i-lubricant okanye i-coolant ukunciphisa ingxabano phakathi kocingo kunye nokufa, okukhokelela ekugqityweni komphezulu ogudileyo. Oku kubalulekile kwizicelo apho imbonakalo yocingo ibalulekile, njengokwenziwa kweengcingo zombane okanye iintambo.

Ngaphezu kokuphucula umphezulu wocingo, inkqubo yokuzoba emanzi ikwanceda ekunciphiseni umngcipheko womphezulu wocingo. iziphene ezifana nemikrwelo okanye amanqaku. Isithambisi okanye isisipholisi esisetyenziswa kwinkqubo yokuzoba emanzi inceda ukukhusela umphezulu wocingo emonakalweni njengoko lutsalwa kwiintsizi. Oku kunokunceda ukuphucula umgangatho uwonke wocingo kunye nokunciphisa ubungakanani benkunkuma eveliswayo ngexesha lenkqubo yokuvelisa.

Olunye uncedo lokusebenzisa umatshini wokuzoba ucingo olumanzi ngocingo lwe-aluminium kukuba lunokunceda ukwandisa imveliso yokuvelisa. inkqubo. I-lubricant okanye i-coolant esetyenziswe kwinkqubo yokudweba emanzi inceda ukunciphisa ubushushu obuveliswa ngexesha lokuzoba, elinokunceda ukwandisa isantya apho ucingo lunokutsalwa khona. Oku kunokunceda ukunciphisa ubungakanani bexesha elifunekayo ukuvelisa ubude obunikiweyo bocingo, okukhokelela ekwandeni kwemveliso kunye neendleko eziphantsi zemveliso.

Ngaphezu koko, ukusetyenziswa komatshini wokuzoba uhlobo olumanzi kunokunceda ukwandisa ubomi bokufa. isetyenziswe kwinkqubo yokuzoba. Isithambiso okanye into yokupholisa esetyenziswa kwinkqubo yokuzoba emanzi inceda ekunciphiseni ukuguga nokukrazuka kwezidumbu, nto leyo enokunceda ukwandisa ubomi bazo. Oku kunokunceda ukunciphisa iindleko zokulondoloza ezinxulumene nomatshini kunye nokuphucula ukusebenza kakuhle kwenkqubo yokuvelisa.

Kuko konke, ukusetyenziswa komatshini wokudweba ucingo olumanzi kwi-aluminium yocingo lubonelela ngeenzuzo ezininzi ezinokunceda ukuphucula umgangatho, imveliso. , kunye nokusebenza kakuhle kwenkqubo yokuvelisa. Ngokunciphisa iziphene zomhlaba, ukuphucula ukugqitywa komphezulu, ukwandisa imveliso, kunye nokwandisa ubomi bokufa, olu hlobo lomatshini sisixhobo esibalulekileyo kubavelisi abafuna ukuvelisa ucingo oluphezulu lwe-aluminium.

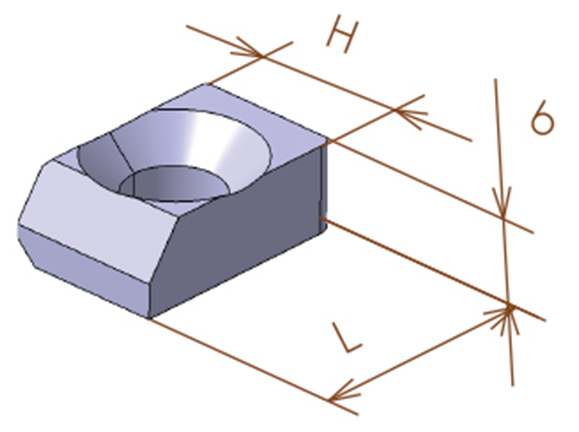

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including aluminium wire. When it comes to wire drawing machines for aluminium wire, there are two main types: wet type and dry type. In this article, we will compare the two types of wire drawing machines and discuss the advantages and disadvantages of each.

Wet Type Wire Drawing Machines use a coolant, typically water-based, to lubricate the wire and dies during the drawing process. This helps to reduce friction and heat, which can improve the quality of the finished wire. The coolant also helps to remove metal shavings and other debris from the wire, resulting in a cleaner surface finish. Additionally, the coolant can help to extend the life of the dies by reducing wear and tear.

On the other hand, Dry Type Wire Drawing Machines do not use any coolant during the drawing process. Instead, the wire and dies are lubricated with a dry lubricant, such as powdered soapstone or graphite. While dry type wire drawing machines are generally simpler and easier to maintain than wet type machines, they may not produce as high-quality wire. The lack of coolant can lead to increased friction and heat, which can result in a rougher surface finish and potentially reduce the lifespan of the dies.

One of the main advantages of Aluminum Wire Breakdown Machine Drawing Machine is their ability to produce high-quality wire with a smooth surface finish. The coolant helps to reduce friction and heat, resulting in a cleaner and more uniform wire. Additionally, the coolant can help to extend the life of the dies, reducing maintenance costs in the long run. However, wet type wire drawing machines can be more complex and expensive to operate than dry type machines, as they require a constant supply of coolant and regular maintenance to ensure proper functioning.

Dry type wire drawing machines, on the other hand, are generally simpler and more cost-effective to operate than wet type machines. They do not require a coolant supply, which can reduce operating costs and maintenance requirements. However, dry type machines may not produce as high-quality wire as wet type machines, as the lack of coolant can lead to increased friction and heat during the drawing process. This can result in a rougher surface finish and potentially reduce the lifespan of the dies.

In conclusion, both wet type and dry type wire drawing machines have their own advantages and disadvantages when it comes to drawing aluminium wire. Wet type machines are capable of producing high-quality wire with a smooth surface finish, but they can be more complex and expensive to operate. Dry type machines, on the other hand, are simpler and more cost-effective to operate, but may not produce as high-quality wire as wet type machines. Ultimately, the choice between wet type and dry type wire drawing machines will depend on the specific requirements of the manufacturing process and the desired quality of the finished wire.

Benefits of Using Wet Type Wire Drawing Machine for Aluminium Wire

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including aluminium wire. One type of wire drawing machine that is commonly used for drawing aluminium wire is the wet type wire drawing machine. This machine offers several benefits that make it a popular choice for manufacturers.

One of the main benefits of using a wet type wire drawing machine for aluminium wire is that it helps to improve the surface finish of the wire. The wet drawing process involves using a lubricant or coolant to reduce friction between the wire and the dies, resulting in a smoother surface finish. This is important for applications where the appearance of the wire is important, such as in the production of electrical wires or cables.

In addition to improving the surface finish of the wire, the wet drawing process also helps to reduce the risk of surface defects such as scratches or marks. The lubricant or coolant used in the wet drawing process helps to protect the surface of the wire from damage as it is pulled through the dies. This can help to improve the overall quality of the wire and reduce the amount of waste produced during the manufacturing process.

Another benefit of using a wet type wire drawing machine for aluminium wire is that it can help to increase the productivity of the manufacturing process. The lubricant or coolant used in the wet drawing process helps to reduce the amount of heat generated during the drawing process, which can help to increase the speed at which the wire can be drawn. This can help to reduce the amount of time required to produce a given length of wire, leading to increased productivity and lower production costs.

Furthermore, the use of a wet type wire drawing machine can also help to extend the life of the dies used in the drawing process. The lubricant or coolant used in the wet drawing process helps to reduce the amount of wear and tear on the dies, which can help to prolong their lifespan. This can help to reduce the maintenance costs associated with the machine and improve the overall efficiency of the manufacturing process.

Overall, the use of a wet type wire drawing machine for aluminium wire offers several benefits that can help to improve the quality, productivity, and efficiency of the manufacturing process. By reducing surface defects, improving surface finish, increasing productivity, and extending the life of dies, this type of machine is a valuable tool for manufacturers looking to produce high-quality aluminium wire.