Table of Contents

Izinto eziLungileyo zokuSebenzisa umatshini wokuWelding Wire Spooling Machine

Indlela yokukhetha umatshini oLungileyo we-Welding Wire Spooling Machine kwiiMfuno zakho

Enye yezinto zokuqala ekufuneka ziqwalaselwe xa ukhetha umatshini we-welding wire spooling luhlobo locingo lwe-welding olusetyenziswayo. Iindidi ezahlukeneyo zocingo lwe-welding zineemitha ezahlukeneyo kunye neempawu, ngoko ke kubalulekile ukukhetha umatshini wokulahla ohambelana nohlobo oluthile locingo olusetyenziswayo. Abanye oomatshini be-spooling benzelwe ukuphatha uluhlu olubanzi lweediameters zocingo, ngelixa abanye bekhethekileyo kwiintlobo ezithile zocingo. Kubalulekile ukuqinisekisa ukuba umatshini we-spooling oyikhethayo uyahambelana nocingo lwe-welding oza kuyisebenzisa ukuze ugweme nayiphi na imiba ngexesha lenkqubo ye-welding.

Enye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha umatshini we-welding wire spooling ubukhulu be-spool. . Ubungakanani be-spool bunokwahluka kakhulu, ukusuka kwi-spools encinci ebamba kuphela iikhilogram ezimbalwa zocingo ukuya kwii-spools ezinkulu ezinokubamba amakhulu eeponti zocingo. Ubungakanani be-spool oyifunayo buya kuxhomekeka kumthamo we-welding oya kuyenza kunye nobukhulu be-welding wire spools oyisebenzisayo ngokuqhelekileyo. Kubalulekile ukukhetha umatshini wokuhlamba onokufaka ubungakanani beespools oza kuzisebenzisa ukuze uqinisekise ukuba unonikezelo oluqhubekayo locingo lwe-welding ngexesha lomsebenzi wakho we-welding.

Ngaphezu kohlobo locingo lwe-welding kunye nobukhulu spool, kukwabalulekile ukuqwalasela isantya kunye nokuchaneka komatshini we-welding wire spooling machine. Abanye oomatshini be-spooling bayilelwe ukusebenza ngesantya esiphezulu, ngelixa abanye befaneleke ngakumbi ukuchaneka ngokuchanekileyo ngesantya esisezantsi. Isantya kunye nokuchaneka komatshini we-spooling kuya kuba nefuthe ekusebenzeni kunye nomgangatho wemisebenzi yakho ye-welding, ngoko ke kubalulekile ukukhetha umatshini ohlangabezana neemfuno zakho ezithile malunga nesantya kunye nokuchaneka. Kwakhona kubalulekile ukuqwalasela umgangatho jikelele kunye nokuthembeka komatshini. Khangela umatshini owakhiwe kakuhle kwaye uhlala ixesha elide, njengoko oku kuya kuqinisekisa ukuba unokumelana nobunzima bokusetyenziswa kwansuku zonke kwindawo ye-welding. Kwakhona kubalulekile ukukhetha umatshini ovela kumenzi ohloniphekileyo kunye nerekhodi yokuvelisa izixhobo eziphezulu ze-welding. Ngokukhetha umgangatho ophezulu kunye nothembekileyo we-welding wire spooling machine, unokuqinisekisa ukuba imisebenzi yakho ye-welding iqhuba kakuhle kwaye ngokufanelekileyo.

Ekuqukumbeleni, ukukhetha umatshini ochanekileyo wokucoca ucingo lwe-welding kubalulekile ekuqinisekiseni ukusebenza kakuhle kunye nokungaphazamiseki kwe-welding. Cinga izinto ezifana nohlobo locingo lwe-welding, ubukhulu be-spool, isantya kunye nokuchaneka komatshini, kunye nomgangatho jikelele kunye nokuthembeka komatshini xa usenza ukhetho lwakho. Ngokuzivavanya ngononophelo ezi zinto kunye nokukhetha umatshini ohlangabezana neemfuno zakho ezithile, unokuqinisekisa ukuba imisebenzi yakho ye-welding iyasebenza, inemveliso, kwaye ikumgangatho ophezulu.

How to Choose the Right Welding Wire Spooling Machine for Your Needs

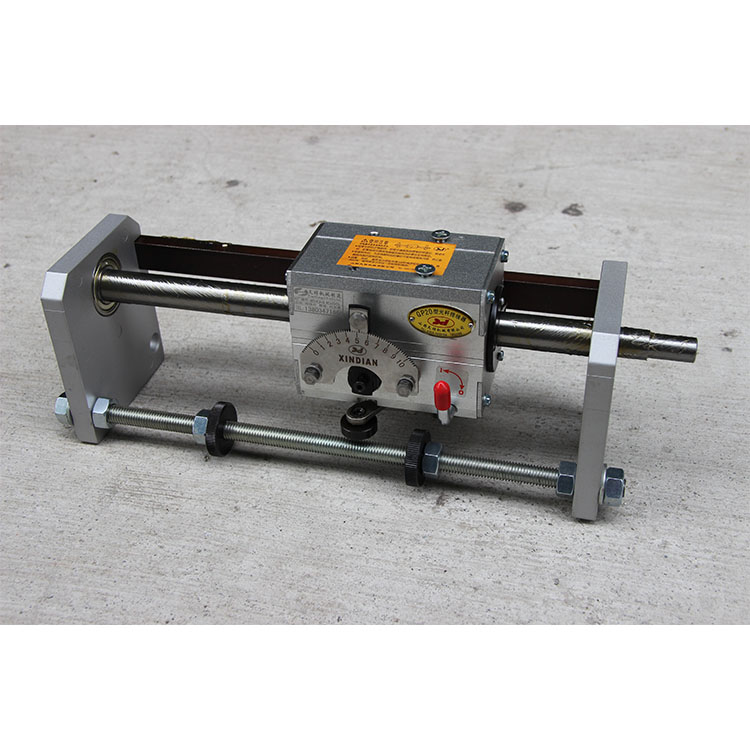

Welding wire spooling machines are essential tools for any welding operation, as they help to efficiently feed welding wire into the welding torch. Choosing the right Horizontal Spooling Machine for your needs is crucial to ensure smooth and uninterrupted welding operations. There are several factors to consider when selecting a welding wire spooling machine, including the type of welding wire being used, the size of the spool, and the speed and accuracy of the machine.

One of the first things to consider when choosing a welding wire spooling machine is the type of welding wire being used. Different types of welding wire have different diameters and properties, so it is important to select a spooling machine that is compatible with the specific type of wire being used. Some spooling machines are designed to handle a wide range of wire diameters, while others are more specialized for specific types of wire. It is important to ensure that the spooling machine you choose is compatible with the welding wire you will be using to avoid any issues during the welding process.

Another important factor to consider when choosing a welding wire spooling machine is the size of the spool. Spool sizes can vary greatly, from small spools that hold only a few pounds of wire to large spools that can hold hundreds of pounds of wire. The size of the spool you need will depend on the volume of welding you will be doing and the size of the welding wire spools you typically use. It is important to choose a spooling machine that can accommodate the size of spools you will be using to ensure that you have a continuous supply of welding wire during your welding operations.

In addition to the type of welding wire and the size of the spool, it is also important to consider the speed and accuracy of the welding wire spooling machine. Some spooling machines are designed for high-speed operation, while others are more suited for precision spooling at slower speeds. The speed and accuracy of the spooling machine will impact the efficiency and quality of your welding operations, so it is important to choose a machine that meets your specific needs in terms of speed and accuracy.

When selecting a welding wire spooling machine, it is also important to consider the overall quality and reliability of the machine. Look for a machine that is well-built and durable, as this will ensure that it can withstand the rigors of daily use in a welding environment. It is also important to choose a machine from a reputable manufacturer with a track record of producing high-quality welding equipment. By choosing a high-quality and reliable welding wire spooling machine, you can ensure that your welding operations run smoothly and efficiently.

In conclusion, choosing the right welding wire spooling machine is essential for ensuring smooth and uninterrupted welding operations. Consider factors such as the type of welding wire, the size of the spool, the speed and accuracy of the machine, and the overall quality and reliability of the machine when making your selection. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your welding operations are efficient, productive, and of the highest quality.