Table of Contents

Indlela yokukhetha i-Welding eLungileyo yocingo lweDrum Packer kwiShishini lakho

Uomatshini bokuPakisha iGubu loNxibelelwano lwe-WeldingEnye into ebalulekileyo ekufuneka iqwalaselwe sisantya sompakishi. Umpakishi okhawulezayo unokunceda ukwandisa imveliso kunye nokusebenza kakuhle kwimisebenzi yakho. Nangona kunjalo, kubalulekile ukubetha ibhalansi phakathi kwesantya kunye nomgangatho wokuqinisekisa ukuba ucingo lwe-welding lupakishwe ngokuchanekileyo nangokukhuselekileyo. Jonga umpakishi obonelela ngolungelelwano olulungileyo phakathi kwesantya kunye nokuchaneka ukuhlangabezana neemfuno zeshishini lakho.

Ukusetyenziswa ngokulula yenye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha i-Welding Wire Drum Packer. Ufuna ipakethe ekulula ukuyisebenzisa kunye nokugcina, kunye nolawulo olulula kunye neempawu ezisebenziseka lula. I-packer ekulula ukuyisebenzisa iya kunceda ukulungelelanisa imisebenzi yakho kunye nokunciphisa umngcipheko weempazamo kwinkqubo yokupakisha. Khangela ipakisha oza nemiyalelo ecacileyo kunye nezixhobo zoqeqesho ukunceda abasebenzi bakho bafunde ngokukhawuleza ukusebenzisa isixhobo.

Izinto eziluncedo zokuSebenzisa

I-Welding Wire Packer

s For Industrial Applications

Ekuqukunjelweni, i-welding wire drum packers sisixhobo esibalulekileyo kumashishini asebenzisa i-welding wire kwimisebenzi yabo. Aba matshini banika uluhlu lweenzuzo, ukusuka ekusebenzeni okwandisiweyo kunye nokuchaneka ukuphuculwa kokhuseleko kunye nomgangatho. Ngokwenza utyalo-mali kwipaki yegubu, iinkampani zinokuphucula iinkqubo zazo zokupakisha kwaye ziqinisekise ukuba ucingo lwabo lokuwelda lugcinwa kwaye luthuthwa ngokukhuselekileyo nangokungaguquguqukiyo.

In conclusion, choosing the right welding wire drum packer for your business is a crucial decision that can have a significant impact on your operations. Consider factors such as capacity, speed, durability, ease of use, and cost when selecting a packer. By carefully evaluating your business needs and requirements, you can find a packer that meets your needs and helps improve efficiency and productivity in your welding wire packaging process.

Merits Of Using Welding Wire Drum Packers For Industrial Applications

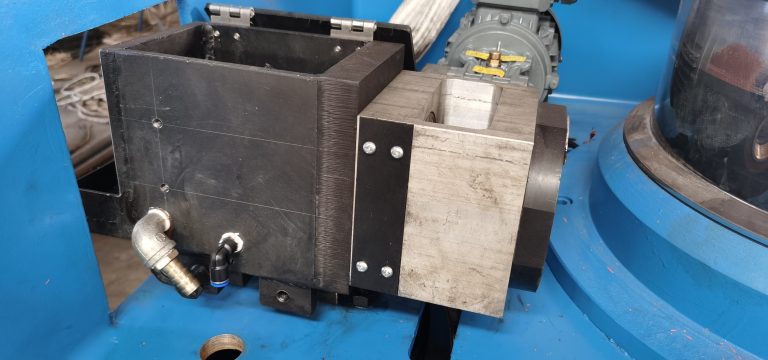

Welding wire drum packer is an essential component in many industrial applications, used for joining metals together in a variety of processes. To ensure that welding wire is stored and transported efficiently, many industries rely on welding wire drum packer. These specialized machines are designed to package welding wire into drums, making it easier to handle and transport.

One of the key merits of using a welding wire drum packer is the convenience it offers in packaging welding wire. Instead of manually packaging welding wire into drums, which can be time-consuming and labor-intensive, a drum packer automates the process, saving time and reducing the risk of injury to workers. This increased efficiency can lead to cost savings for companies, as it allows them to package welding wire more quickly and with fewer resources.

In addition to the convenience of automating the packaging process, welding wire drum packers also ensure that welding wire is packaged securely and accurately. These machines are designed to measure and cut welding wire to the desired length before packaging it into drums, ensuring that each drum contains the correct amount of wire. This precision helps to prevent waste and ensures that welding wire is packaged consistently, reducing the risk of errors in the welding process.

Another benefit of using a welding wire drum packer is the improved safety it provides for workers. By automating the packaging process, drum packers reduce the need for manual handling of welding wire, which can be heavy and awkward to lift. This can help to prevent injuries and reduce the risk of musculoskeletal disorders among workers, creating a safer working environment for all involved.

Furthermore, welding wire drum packers can help to improve the overall quality of welding work. By ensuring that welding wire is packaged accurately and securely, these machines help to prevent contamination and damage to the wire during storage and transportation. This can lead to better welding results, as the quality of the welding wire is maintained throughout the process.

Overall, the benefits of using a welding wire drum packer for industrial applications are clear. These machines offer convenience, efficiency, accuracy, safety, and quality improvements for companies that rely on welding wire in their operations. By investing in a drum packer, companies can streamline their packaging processes, reduce waste, and create a safer working environment for their employees.

In conclusion, welding wire drum packers are a valuable tool for industries that use welding wire in their operations. These machines offer a range of benefits, from increased efficiency and accuracy to improved safety and quality. By investing in a drum packer, companies can enhance their packaging processes and ensure that their welding wire is stored and transported securely and consistently.