Table of Contents

Izinto eziluncedo zokuSebenzisa i-Automated Welding Electrodes Machinery

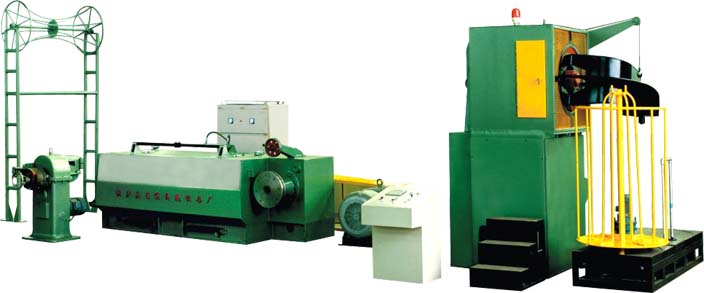

I-welding electrode plant machine cutting wire cutting idlala indima ebalulekileyo kwi-welding industry, ibonelela ngezixhobo eziyimfuneko kunye nezixhobo zokwenza i-welds eqinile kunye neyomelele. Enye yenkqubela phambili ephambili kwitekhnoloji ye-welding kukuphuhliswa koomatshini be-welding electrode. Obu buchwephesha bokusungula bubonelela ngoluhlu olubanzi lweenzuzo ezenza kube lukhetho olukhethwayo kwiingcali ezininzi zokuwelda.

Indlela yokukhetha oomatshini abaLungileyo be-Welding Electrodes kwiShishini lakho

Enye yezinto zokuqala ekufuneka ziqwalaselwe xa ukhetha i-Wire Straightening And Cutting Machines luhlobo lwenkqubo ye-welding oya kuyisebenzisa. Iinkqubo ze-welding ezahlukeneyo zifuna iintlobo ezahlukeneyo zoomatshini be-electrode. Umzekelo, ukuba uya kusebenzisa i-arc welding yentsimbi ekhuselweyo (SMAW), uya kufuna uhlobo olwahlukileyo loomatshini kunokuba uya kusebenzisa i-gas metal arc welding (GMAW) okanye i-flux-cored arc welding (FCAW). Kubalulekile ukuthelekisa oomatshini kunye nenkqubo yokuwelda ukuqinisekisa ukusebenza ngokupheleleyo.

Enye into ebalulekileyo emayiqwalaselwe xa ukhetha oomatshini bokuwelda i-electrode bubukhulu kunye namandla oomatshini. Ubungakanani kunye nomthamo womatshini owufunayo buya kuxhomekeka kumthamo womsebenzi we-welding oza kuwenza. Ukuba uya kuba wenza umthamo ophezulu womsebenzi we-welding, uya kufuna oomatshini abakhulu kunye nomthamo ophezulu. Kwelinye icala, ukuba uza kube usenza umthamo ophantsi womsebenzi wokuwelda, usenokukwazi ukuphumelela ngoomatshini abancinci.

Kukwabalulekile ukuqwalasela umgangatho kunye nokuthembeka koomatshini bokuwelda i-electrode oyicingayo. Oomatshini abakumgangatho ophezulu baya kuthembeka ngakumbi kwaye baya kuhlala ixesha elide, ukongela imali ekuhambeni kwexesha. Kufanelekile ukutyala imali koomatshini abakumgangatho ophezulu ukuqinisekisa ukuba iinkqubo zakho zokuwelda zihamba kakuhle nangempumelelo.

Xa ukhetha oomatshini bokuwelda i-electrode, kubalulekile kwakhona ukuqwalasela iimpawu kunye nesakhono soomatshini. Abanye oomatshini banokuba neempawu eziphambili ezinokuphucula ukusebenza kakuhle kunye nomgangatho weenkqubo zakho zokuwelda. Ngokomzekelo, abanye oomatshini basenokuba neenkqubo zokutyisa ezizenzekelayo okanye izixhobo zokulawula idijithali ezenza kube lula ukuzisebenzisa. Qwalasela iimpawu ezibalulekileyo kuwe nakwishishini lakho xa ukhetha oomatshini bokuwelda i-electrode.

Iindleko yenye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha oomatshini bokuwelda i-electrode. Kubalulekile ukuqwalasela kungekuphela nje iindleko zangaphambili zoomatshini kodwa neendleko zexesha elide, ezinjengokulungisa neendleko zokusebenza. Kubalulekile ukukhetha oomatshini abahambelana nohlahlo lwabiwo-mali lwakho ngelixa uhlangabezana neemfuno zakho.

Ekuqukumbeleni, ukukhetha oomatshini abafanelekileyo be-electrode be-electrode kwishishini lakho kubalulekile ekuqinisekiseni impumelelo kunye nomgangatho weenkqubo zakho zokuwelda. Cinga izinto ezifana nohlobo lwenkqubo ye-welding, ubungakanani kunye nomthamo, umgangatho kunye nokuthembeka, iimpawu kunye nezakhono, kunye neendleko xa ukhetha umatshini we-welding electrode. Ngokuqwalasela ngononophelo ezi zinto, ungakhetha oomatshini abaya kunceda ishishini lakho liphumelele kushishino lokuwelda

Welding electrodes machinery is an essential component for any business involved in welding operations. Choosing the right welding electrodes machinery can make a significant difference in the efficiency and quality of your welding processes. There are several factors to consider when selecting welding electrodes machinery for your business.

One of the first things to consider when choosing wire straightening and cutting machines are the type of welding process you will be using. Different welding processes require different types of electrodes machinery. For example, if you will be using shielded metal arc welding (SMAW), you will need a different type of machinery than if you will be using gas metal arc welding (GMAW) or flux-cored arc welding (FCAW). It is essential to match the machinery to the welding process to ensure optimal performance.

Another important factor to consider when choosing welding electrodes machinery is the size and capacity of the machinery. The size and capacity of the machinery you need will depend on the volume of welding work you will be doing. If you will be doing a high volume of welding work, you will need larger machinery with a higher capacity. On the other hand, if you will be doing a lower volume of welding work, you may be able to get by with smaller machinery.

It is also essential to consider the quality and reliability of the welding electrodes machinery you are considering. High-quality machinery will be more reliable and will last longer, saving you money in the long run. It is worth investing in high-quality machinery to ensure that your welding processes run smoothly and efficiently.

When choosing welding electrodes machinery, it is also important to consider the features and capabilities of the machinery. Some machinery may have advanced features that can improve the efficiency and quality of your welding processes. For example, some machinery may have automatic feeding systems or digital controls that make it easier to use. Consider the features that are important to you and your business when choosing welding electrodes machinery.

Cost is another important factor to consider when choosing welding electrodes machinery. It is essential to consider not only the upfront cost of the machinery but also the long-term costs, such as maintenance and operating costs. It is important to choose machinery that fits within your budget while still meeting your needs.

In conclusion, choosing the right welding electrodes machinery for your business is essential for ensuring the efficiency and quality of your welding processes. Consider factors such as the type of welding process, size and capacity, quality and reliability, features and capabilities, and cost when selecting welding electrodes machinery. By carefully considering these factors, you can choose machinery that will help your business succeed in the welding industry.