Table of Contents

Indlela yokuGcina ngokuchanekileyo kunye nokuQothulwa kweNgxaki kwiYunithi yeNtlawulo yoHlobo oluthe nkqo kwiNkqubo yoMzobo wocingo

Izinto eziluncedo zokuSebenzisa iYunithi yeNtlawulo yoHlobo oluthe nkqo kwiNkqubo yoMzobo wocingo

Ukongezelela kwi-design yokulondoloza indawo kunye nokulula ukusebenza, iiyunithi zokuhlawula uhlobo oluthe nkqo zibonelela ngolawulo loxinzelelo oluphuculweyo. Ukuqhelaniswa ngokuthe nkqo kweyunithi ivumela ulawulo olungcono malunga nokunyanzeliswa kocingo njengoko lutyiswa kumatshini wokuzoba. Oku kubalulekile ekuqinisekiseni umgangatho ohambelanayo kunye nokusebenza kweemveliso zocingo ezigqityiweyo. Ngokugcina uxinzelelo olufanelekileyo kuyo yonke inkqubo yokuzoba, abavelisi banokunciphisa umngcipheko weziphene kwaye baphucule umgangatho uwonke weemveliso zabo.

Ngaphezu koko, iiyunithi zokuhlawula uhlobo oluthe nkqo ziyaziwa ngokuguquguquka kwazo. Ezi yunithi ziyakwazi ukufumana uluhlu olubanzi lweengcingo kunye neentlobo, okwenza ukuba zilungele usetyenziso oluhlukeneyo. Nokuba ngaba abavelisi bavelisa iingcingo zombane ezibhityileyo okanye iingcingo ezishinyeneyo zokubiya, uhlobo oluthe nkqo lweyunithi yentlawulo lunokulungelelaniswa lula ukuhlangabezana neemfuno zabo ezithile. Oku kuguquguquka kuvumela abavelisi ukuba bavumelane nokutshintsha iimfuno zemveliso kwaye bavelise uluhlu oluhlukeneyo lweemveliso zocingo ngokulula.

Kuko konke, iingenelo zokusebenzisa iyunithi yokuhlawula yohlobo oluthe nkqo kwinkqubo yokudweba ucingo icacile. Ukusuka kuyilo lokonga indawo kunye nokusebenza ngokulula ukuya kulawulo oluphuculweyo lwentambo kunye nokuguquguquka kwezinto ezininzi, ezi yunithi zibonelela ngeenzuzo ezininzi kubavelisi. Ngokutyala imali kwiyunithi yentlawulo yohlobo oluthe nkqo, abavelisi banokuphucula ukusebenza kakuhle, ukhuseleko, kunye nomgangatho wenkqubo yabo yokuzoba ngocingo, ekugqibeleni ikhokelele kwimpumelelo enkulu ekuvelisweni kweemveliso zocingo.

Advantages of Using Vertical Type Payoff Unit for Wire Drawing Process

The wire drawing process is a crucial step in the production of various types of wire products, such as electrical wires, cables, and fencing. One of the key components in this process is the payoff unit, which is responsible for supplying the wire to the drawing machine. There are different types of payoff units available, with the vertical type being one of the most popular choices among manufacturers. In this article, we will discuss the advantages of using a vertical type payoff unit for the wire drawing process.

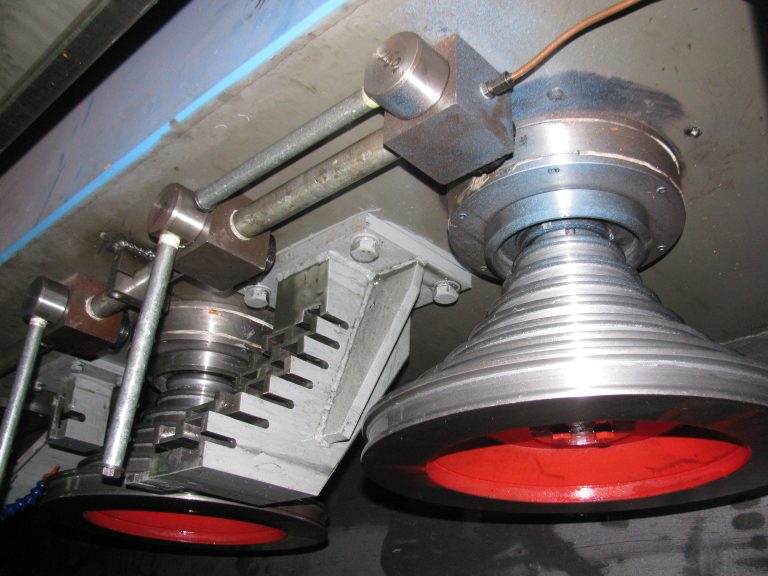

One of the main advantages of a Overhead Payoff unit is its space-saving design. Unlike horizontal payoff units, which require a significant amount of floor space, vertical units are mounted on a vertical frame, allowing for a more compact footprint. This is especially beneficial for manufacturers with limited space in their production facilities, as it allows them to maximize the use of available space.

Another advantage of vertical type payoff units is their ease of operation. These units are designed to be user-friendly, with controls and adjustments easily accessible to operators. This makes it easier for operators to set up and monitor the wire drawing process, leading to increased efficiency and productivity. Additionally, vertical payoff units are typically equipped with safety features to protect operators from potential hazards, further enhancing the overall safety of the production process.

In addition to space-saving design and ease of operation, vertical type payoff units offer improved wire tension control. The vertical orientation of the unit allows for better control over the tension of the wire as it is fed into the drawing machine. This is important for ensuring consistent quality and performance of the finished wire products. By maintaining proper tension throughout the drawing process, manufacturers can reduce the risk of defects and improve the overall quality of their products.

Furthermore, vertical type payoff units are known for their versatility. These units can accommodate a wide range of wire sizes and types, making them suitable for a variety of applications. Whether manufacturers are producing thin electrical wires or thick fencing wires, a vertical type payoff unit can be easily adjusted to meet their specific requirements. This flexibility allows manufacturers to adapt to changing production needs and produce a diverse range of wire products with ease.

Overall, the advantages of using a vertical type payoff unit for the wire drawing process are clear. From space-saving design and ease of operation to improved wire tension control and versatility, these units offer numerous benefits to manufacturers. By investing in a vertical type payoff unit, manufacturers can enhance the efficiency, safety, and quality of their wire drawing process, ultimately leading to greater success in the production of wire products.