Table of Contents

IiNzuzo zokuSebenzisa iYunithi yeNtlawulo yoHlobo oluthe nkqo kwiNkqubo yokuzoba ngocingo

Kwinkqubo yokuzoba ngocingo, iyunithi yokuhlawula yohlobo oluthe nkqo idlala indima ebalulekileyo ekuqinisekiseni ukusebenza kakuhle nangokufanelekileyo. Olu hlobo lweyunithi yentlawulo yenzelwe ukuphatha i-spools enkulu yocingo kwaye ibondle kumatshini wokuzoba ngokuchanekileyo kunye nokulawula. Kukho iinzuzo ezininzi zokusebenzisa iyunithi yentlawulo yohlobo oluthe nkqo, esiza kuyiphonononga kweli nqaku.

Enye yeenzuzo eziphambili zeyunithi yentlawulo yohlobo oluthe nkqo kuyilo lokulondoloza indawo. Ngokungafaniyo neeyunithi zentlawulo ezithe tye, ezifuna isixa esibalulekileyo sendawo yomgangatho, iiyunithi ezithe nkqo zinokufakwa kwindawo encinci kakhulu. Oku kunenzuzo ngakumbi kwizixhobo zokuzoba ngocingo ezinendawo encinci, ebavumela ukuba bakhulise amandla abo okuvelisa ngaphandle kokuncama ukusebenza kakuhle.

Olunye uncedo lweyunithi yentlawulo yohlobo oluthe nkqo kukukwazi ukuphatha uluhlu olubanzi lweengcingo kunye nezixhobo. Nokuba uzobe ubhedu, i-aluminiyam, intsimbi, okanye naluphi na olunye uhlobo locingo, iyunithi ethe nkqo inokwamkela iisayizi ezahlukeneyo zespool kunye nobunzima ngokulula. Oku kuguquguquka kuyenza ibe yi-asethi yexabiso kwimisebenzi yokuzoba ngocingo esebenza ngezinto ezahlukeneyo.

Indlela yokugcinwa ngokufanelekileyo kunye nokuSebenzisa iYunithi yeNtlawulo yoHlobo oluthe nkqo

Ukuthelekiswa kweeYunithi zeNtlawulo yoHlobo olwahlukileyo oluthe nkqo olufumaneka kwiMarike

Kwinkqubo yokuzoba ngocingo, iyunithi yentlawulo idlala indima ebalulekileyo ekuqinisekiseni ukusebenza ngokutyibilikayo nangokufanelekileyo. Iyunithi yokuhlawula inoxanduva lokubonelela ngocingo kumatshini wokuzoba kwi-tension kunye nesantya esihambelanayo. Kukho iintlobo ngeentlobo zeeyunithi zentlawulo ezikhoyo kwimarike, kubandakanywa iintlobo ezithe tye kunye nezithe nkqo. Kule nqaku, siya kugxininisa kwiyunithi yokuhlawula uhlobo oluthe nkqo kwaye sithelekise iinketho ezahlukeneyo ezikhoyo.

Inye yeenzuzo eziphambili zeyunithi yentlawulo yohlobo oluthe nkqo yi-compact design yayo, evumela ukudibanisa lula kwiisethingi zomzobo wocingo ezikhoyo. Olu hlobo lweyunithi yentlawulo idla ngokuxhonywa kwisakhelo esithe nkqo, kunye ne-spool yocingo ebekwe ngaphezulu komatshini wokuzoba. Olu lungelelwaniso lunceda ukucutha unyawo lweyunithi, iyenze ilungele izibonelelo ezinendawo enyiniweyo.

Olunye uncedo lweyunithi yentlawulo yohlobo oluthe nkqo kukukwazi kwayo ukuphatha uluhlu olubanzi lweesayizi zocingo kunye nemathiriyeli. Ezi yunithi zenzelwe ukuhlalisa ubungakanani obuhlukeneyo be-spool kunye nobunzima, okuvumela ukuguquguquka kwiintlobo zocingo ezinokucutshungulwa. Oku kuguquguquka kwenza iiyunithi zentlawulo yohlobo oluthe nkqo lulungele usetyenziso olwahlukeneyo, ukusuka kumzobo wocingo olucikizekileyo ukuya kwiinkqubo zemizi-mveliso enzima.

Xa uthelekisa iiyunithi zentlawulo zohlobo oluthe nkqo, kubalulekile ukuqwalasela imiba efana nesantya, ulawulo loxinzelelo, kunye nokulula. yokusebenza. Ezinye iiyunithi zixhotyiswe ngeempawu eziphambili ezifana neenkqubo zolawulo loxinzelelo lwe-elektroniki, ezinceda ukugcina amanqanaba okuxinana angaguqukiyo kuyo yonke inkqubo yokuzoba. Oku kunokubangela umgangatho ophezulu weemveliso zocingo ezineziphene ezincinci.

Ukongeza kulawulo loxinzelelo, isantya yenye into ebalulekileyo ekufuneka iqwalaselwe xa ukhetha iyunithi yentlawulo yohlobo oluthe nkqo. Ezinye iiyunithi ziyakwazi ukusebenza ngesantya esiphezulu, ezivumela ukwanda kwemveliso kunye nokugqithisa. Nangona kunjalo, kubalulekile ukuqinisekisa ukuba iyunithi iyahambelana neemfuno zesantya somatshini wokudweba ukuphepha nayiphi na imiba ngokuqhawula ucingo okanye ezinye iingxaki.

Ukulula kokusebenza kwakhona kuyingqwalasela ephambili xa ukhetha iyunithi yokuhlawula yohlobo oluthe nkqo. Iiyunithi ezixhotyiswe ngolawulo olusebenziseka lula kunye nojongano lwenza kube lula kubaqhubi ukuseta kunye nokulungelelanisa iyunithi njengoko kufuneka. Oku kunokunceda ukunciphisa ixesha lokuphumla kunye nokuphucula ukusebenza kakuhle ngokubanzi kwinkqubo yokudweba ucingo.

Ekuqukunjelweni, iiyunithi zokuhlawula uhlobo oluthe nkqo zibonelela ngesisombululo esibambeneyo nesiguquguqukayo sezicelo zokudweba ucingo. Ngokuthelekisa iinketho ezahlukeneyo ezikhoyo kwimarike, abavelisi banokukhetha iyunithi ehlangabezana neemfuno zabo ezithile zesantya, ulawulo loxinzelelo, kunye nokusebenza ngokulula. Ngeyunithi yentlawulo efanelekileyo ekhoyo, imisebenzi yokuzoba ngocingo inokuhamba kakuhle kwaye ngokufanelekileyo, okukhokelela kwiimveliso zocingo ezikumgangatho ophezulu kumashishini ahlukeneyo.

Comparison of Different Vertical Type Payoff Units Available in the Market

In the wire drawing process, the payoff unit plays a crucial role in ensuring smooth and efficient operation. The payoff unit is responsible for supplying the wire to the drawing machine at a consistent tension and speed. There are various types of payoff units available in the market, including horizontal and vertical types. In this article, we will focus on the vertical type payoff unit and compare different options available.

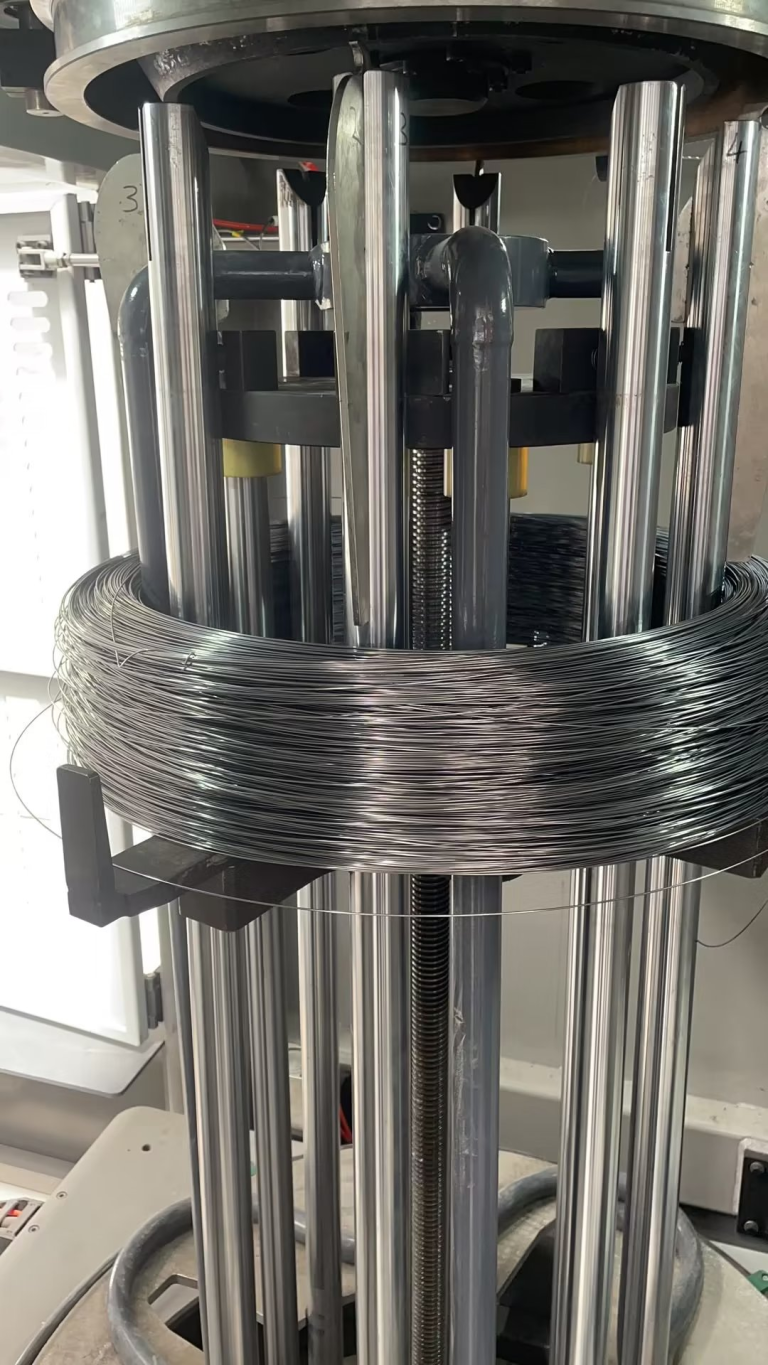

One of the key advantages of a vertical type payoff unit is its compact design, which allows for easy integration into existing wire drawing setups. This type of payoff unit is typically mounted on a vertical frame, with the wire spool positioned above the drawing machine. This configuration helps to minimize the footprint of the unit, making it ideal for facilities with limited space.

Another benefit of a vertical type payoff unit is its ability to handle a wide range of wire sizes and materials. These units are designed to accommodate different spool sizes and weights, allowing for flexibility in the types of wire that can be processed. This versatility makes vertical type payoff units suitable for a variety of applications, from fine wire drawing to heavy-duty industrial processes.

When comparing different vertical type payoff units, it is important to consider factors such as speed, tension control, and ease of operation. Some units are equipped with advanced features such as electronic tension control systems, which help to maintain consistent tension levels throughout the drawing process. This can result in higher quality wire products with minimal defects.

In addition to tension control, speed is another important factor to consider when choosing a vertical type payoff unit. Some units are capable of high-speed operation, allowing for increased productivity and throughput. However, it is important to ensure that the unit is compatible with the speed requirements of the drawing machine to avoid any issues with wire breakage or other problems.

Ease of operation is also a key consideration when selecting a vertical type payoff unit. Units that are equipped with user-friendly controls and interfaces make it easier for operators to set up and adjust the unit as needed. This can help to reduce downtime and improve overall efficiency in the wire drawing process.

In conclusion, vertical type payoff units offer a compact and versatile solution for wire drawing applications. By comparing different options available in the market, manufacturers can choose a unit that meets their specific requirements for speed, tension control, and ease of operation. With the right payoff unit in place, wire drawing operations can run smoothly and efficiently, resulting in high-quality wire products for a variety of industries.