Table of Contents

Izinto eziluncedo zokuSebenzisa iNxibelela yeDrop eNqobileyo yokuThatha iNxibelelwano yeNsimbi yeKhabhoni ePhezulu

Iingcebiso zokuSebenzisa ngokuLungileyo i-Coiler yokuLahla eNgqo kwi-Thatha-Up High Carbon Steel Wire

Ukongezelela, kubalulekile ukubeka iliso ukunyanzeliswa kocingo njengoko luhlanganiswe. Ucingo oluphezulu lwekhabhoni lunokuba novelwano kutshintsho loxinzelelo, ngoko ke kubalulekile ukuba ubeke iliso elibukhali kwizicwangciso zoxinzelelo kuyo yonke inkqubo yokubopha. Ukulungelelanisa ukuxhatshazwa njengoko kufuneka kuya kunceda ukuthintela nayiphi na imiba ngocingo kunye nokuqinisekisa i-coil yomgangatho ophezulu.

Enye ingcebiso ebalulekileyo ekusebenzeni ngokufanelekileyo i-coiler yokulahla ngokuthe nkqo kukuhlola rhoqo umatshini ukuba kukho naziphi na iimpawu zokuguga okanye umonakalo. Oku kubandakanya ukujonga iibheringi, iigiya, kunye nezinye iindawo ezihambayo kuzo naziphi na iimpawu zokunxiba. Ukugcinwa rhoqo kunye nokuhlolwa kuya kunceda ukuthintela nakuphi na ukuphuka okungalindelekanga kunye nokuqinisekisa ukuba umatshini usebenza ngokusemandleni akho.

Ngaphezu kokugcinwa rhoqo, kubalulekile ukugcina indawo yokujiya icocekile kwaye ingenankunkuma. Ucingo oluphezulu lwe-carbon steel luyakwazi ukuthabatha ukungcola kunye ne-debris, ezinokuchaphazela umgangatho wekhoyili. Ngokugcina indawo yokudibanisa icocekile kwaye ingenazo iinkunkuma, unokuqinisekisa i-coil yekhwalithi ephezulu rhoqo.

Okokugqibela, kubalulekile ukulandela zonke izikhokelo zokhuseleko kunye neenkqubo xa usebenzisa i-coiler yokulahla ngokuthe nkqo. Oku kuquka ukunxiba izixhobo zokhuseleko ezifanelekileyo, ezinjengeeglavu kunye neendondo zokhuseleko, kunye nokulandela zonke iiprothokholi zokhuseleko ezichazwe kwincwadana yemigaqo yomatshini. Ngokubeka phambili ukhuseleko, unokuthintela iingozi kunye nokuqinisekisa indawo ekhuselekileyo yokusebenza kwakho kunye nabanye.

Ekuqukumbeleni, ukusebenza ngokufanelekileyo i-coiler yokulahla i-vertical drop for take-up high carbon steel wire kufuna ingqalelo kwiinkcukacha, ukuseta ngokufanelekileyo, kunye nokugcinwa rhoqo. Ngokulandela ezi ngcebiso, unokuqinisekisa ukuba inkqubo yokudibanisa egudileyo kwaye esebenzayo kwaye uvelise iikhoyili ezikumgangatho ophezulu ngalo lonke ixesha. Khumbula ukuhoya uxinzelelo, isantya, kunye nokucoceka, kwaye soloko ubeke phambili ukhuseleko xa usebenzisa umatshini. Ngezi ngcebiso engqondweni, unokusebenzisa ngokufanelekileyo i-coiler yokulahla ngokuthe nkqo ukuze uthathe ucingo oluphezulu lwekhabhoni ngokuzithemba.

Tips for Efficiently Operating a Vertical Drop Coiler for Take-Up High Carbon Steel Wire

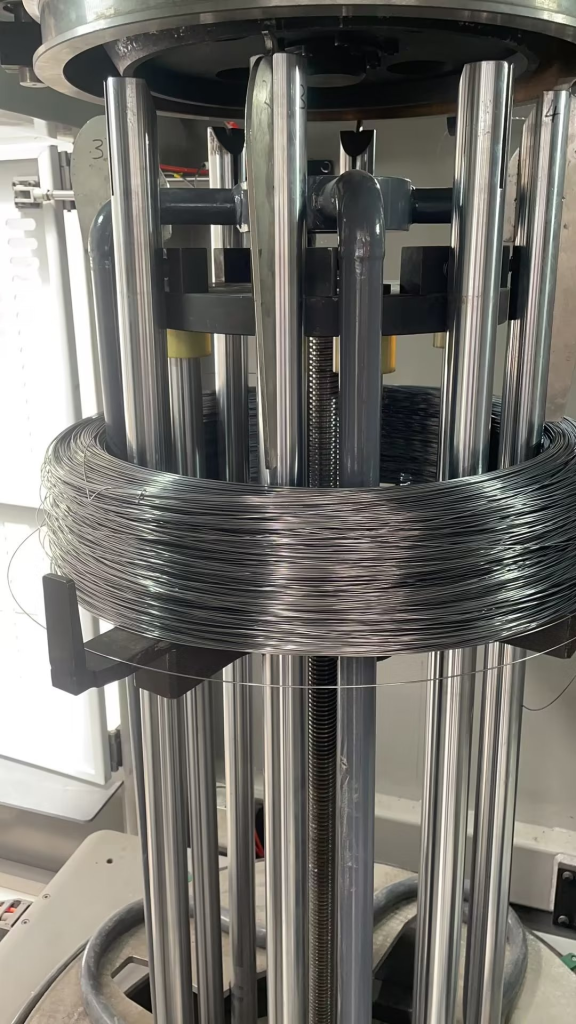

A vertical drop coiler is an essential piece of equipment for efficiently taking up high carbon steel wire. This machine is designed to coil wire in a vertical orientation, allowing for a compact and organized storage solution. Operating a vertical drop coiler requires precision and attention to detail to ensure the wire is coiled correctly and safely. In this article, we will provide some tips for efficiently operating a vertical drop coiler for take-up high carbon steel wire.

First and foremost, it is important to properly set up the vertical drop coiler before beginning the coiling process. This includes adjusting the tension settings, ensuring the wire guide is aligned correctly, and checking that all safety features are in place. Taking the time to properly set up the machine will help prevent any issues during the coiling process and ensure a smooth operation.

When coiling high carbon steel wire, it is important to pay attention to the speed at which the wire is being fed into the coiler. High carbon steel wire is known for its strength and durability, but it can also be prone to tangling if not handled properly. By controlling the speed at which the wire is fed into the coiler, you can prevent tangles and ensure a consistent coil.

Additionally, it is important to monitor the tension of the wire as it is being coiled. High carbon steel wire can be sensitive to tension changes, so it is important to keep a close eye on the tension settings throughout the coiling process. Adjusting the tension as needed will help prevent any issues with the wire and ensure a high-quality coil.

Another important tip for efficiently operating a vertical drop coiler is to regularly inspect the machine for any signs of wear or damage. This includes checking the bearings, gears, and other moving parts for any signs of wear. Regular maintenance and inspections will help prevent any unexpected breakdowns and ensure the machine is operating at its best.

In addition to regular maintenance, it is also important to keep the coiling area clean and free of debris. High carbon steel wire can be prone to picking up dirt and debris, which can affect the quality of the coil. By keeping the coiling area clean and free of debris, you can ensure a high-quality coil every time.

Lastly, it is important to follow all safety guidelines and procedures when operating a vertical drop coiler. This includes wearing appropriate safety gear, such as gloves and safety glasses, and following all safety protocols outlined in the machine’s manual. By prioritizing safety, you can prevent accidents and ensure a safe working environment for yourself and others.

In conclusion, efficiently operating a vertical drop coiler for take-up high carbon steel wire requires attention to detail, proper setup, and regular maintenance. By following these tips, you can ensure a smooth and efficient coiling process and produce high-quality coils every time. Remember to pay attention to tension, speed, and cleanliness, and always prioritize safety when operating the machine. With these tips in mind, you can efficiently operate a vertical drop coiler for take-up high carbon steel wire with confidence.