Table of Contents

Iingcebiso zokuSebenza ngokuLungileyo kwe-Drop Coiler ye-High Carbon Steel Wire Take-Up

Izinto eziluncedo zokuSebenzisa iKhoyila yokuLahla eNgqo kwi-High Carbon Steel Wire Take-Up

Ukongezelela kwi-design yayo yokugcina indawo, ii-coilers zokulahla ezithe nkqo zibonelela ngeempawu eziphuculweyo zokhuseleko xa kuthelekiswa neekhoyila ezithe tye. Nge-coiler yokulahla i-vertical drop, ucingo lukhokelwa ngokuthe ngqo kumatshini wokudweba ucingo ukuya kwiyunithi yokudibanisa, ukuphelisa imfuno yokuphatha ucingo. Oku kunciphisa umngcipheko weengozi kunye nokulimala okuhambelana nokuphatha ucingo oluphezulu lwe-carbon steel, olunokuba nzima kwaye lube nzima ukuqhuba.

. Uyilo oluthe nkqo lwe-coiler luvumela isantya esikhawulezayo sokujika, okukhokelela ekunyuseni kwemveliso kunye nokusebenza kakuhle. Oku kunenzuzo ngokukhethekileyo kumashishini afuna ukuveliswa ngokukhawuleza kocingo lwentsimbi yekhabhoni ephezulu ukuhlangabezana nemfuno.

Enye inzuzo ephambili yokusebenzisa i-coiler yokuwa ngokuthe nkqo kwi-carbon steel high wire take-up kukukwazi ukuvelisa iikhoyili zenxeba eliqinileyo. I-orientation ethe nkqo ye-coiler iqinisekisa ukuba ucingo lulimala ngokulinganayo kwaye luqiniswe, lukhusela ukuxubha kunye nokuqinisekisa umgangatho wekhoyili ohambelanayo. Oku kubalulekile kwiinkqubo ezisezantsi ezifuna iikhoyili ezichanekileyo kunye ezifanayo zocingo lwentsimbi yekhabhoni ephezulu.

Bangakwazi ukufumana ngokulula i-diameters yocingo eyahlukeneyo kunye nobukhulu bekhoyili, okwenza ukuba bafanelekele uluhlu olubanzi lwezicelo ze-carbon steel wire high. Oku kuguquguquka kuvumela abavelisi ukuba batshintshe ngokulula phakathi kweenkcazo ezahlukeneyo zocingo ngaphandle kwesidingo sokuphinda kuqwalaselwe ngokubanzi i-coiler.

Kuko konke, iingenelo zokusebenzisa i-coiler yokulahla i-vertical drop for high carbon steel wire take-up icacile. Ukusuka kuyilo lwayo olugcina indawo kunye neempawu eziphuculweyo zokhuseleko ukuya ekusebenzeni kwayo ngesantya esiphezulu kunye nokukwazi ukuvelisa iikhoyili zamanxeba aqinileyo, iikhoyili ezithe nkqo zinikezela ngeenzuzo ezininzi kubenzi bocingo oluphezulu lwekhabhoni. Ngokuguquguquka kwazo kunye nokusebenza kakuhle, iikhoyila ezithe nkqo ziyinto exabisekileyo kuyo nayiphi na indawo yokuvelisa ejonge ukukhulisa inkqubo yokuthatha ucingo kunye nokuphucula imveliso iyonke.

In conclusion, a Vertical Drop Coiler is a valuable piece of equipment for efficiently coiling high carbon steel wire onto a spool or reel. By following these tips for efficient operation, operators can ensure that the coiling process runs smoothly and that the wire is wound neatly and evenly. With proper setup, monitoring, maintenance, and safety precautions, operators can maximize the performance of their vertical drop coiler and produce high-quality coiled wire for further processing or shipment.

Advantages of Using Vertical Drop Coiler for High Carbon Steel Wire Take-Up

High carbon steel wire is a crucial material used in various industries such as automotive, construction, and manufacturing. To ensure the efficient production of high carbon steel wire, it is essential to have a reliable and efficient take-up system in place. One popular option for take-up systems is the vertical drop coiler, which offers several advantages over traditional horizontal coilers.

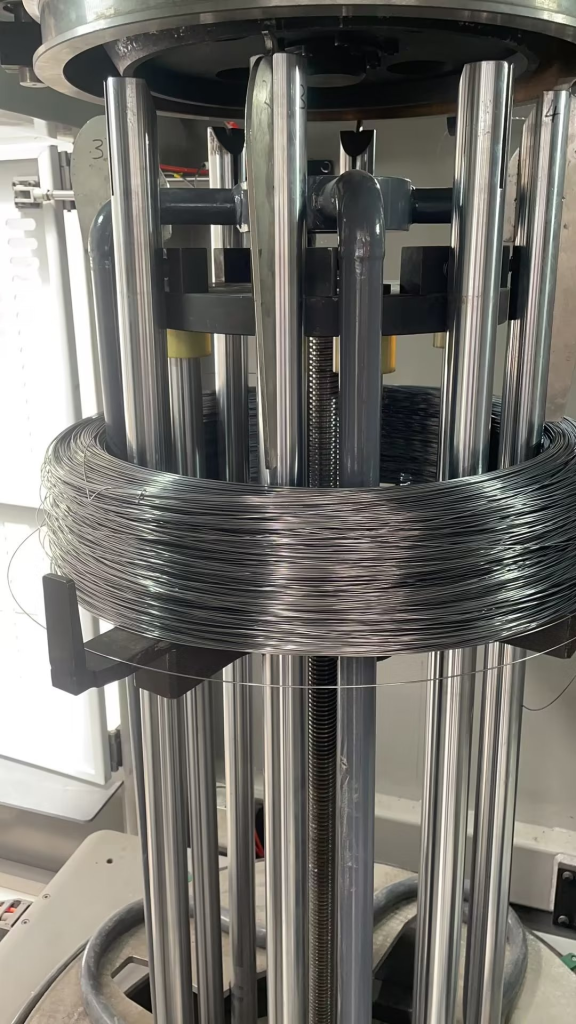

One of the main advantages of using a Vertical Wire Drop Coiler for high carbon steel wire take-up is its space-saving design. Unlike horizontal coilers that require a large footprint to accommodate the wire as it is wound, vertical drop coilers can be installed in a more compact space. This is especially beneficial for facilities with limited floor space or those looking to optimize their production layout.

In addition to its space-saving design, vertical drop coilers offer improved safety features compared to horizontal coilers. With a vertical drop coiler, the wire is guided directly from the wire drawing machine to the coiling unit, eliminating the need for manual handling of the wire. This reduces the risk of accidents and injuries associated with handling high carbon steel wire, which can be heavy and difficult to maneuver.

Furthermore, vertical drop coilers are known for their high-speed operation, making them ideal for high-volume production environments. The vertical design of the coiler allows for faster winding speeds, resulting in increased productivity and efficiency. This is particularly advantageous for industries that require rapid production of high carbon steel wire to meet demand.

Another key advantage of using a vertical drop coiler for high carbon steel wire take-up is its ability to produce tightly wound coils. The vertical orientation of the coiler ensures that the wire is wound evenly and tightly, preventing tangling and ensuring consistent coil quality. This is essential for downstream processes that require precise and uniform coils of high carbon steel wire.

Additionally, vertical drop coilers are known for their versatility and flexibility. They can easily accommodate different wire diameters and coil sizes, making them suitable for a wide range of high carbon steel wire applications. This versatility allows manufacturers to easily switch between different wire specifications without the need for extensive reconfiguration of the coiler.

Overall, the advantages of using a vertical drop coiler for high carbon steel wire take-up are clear. From its space-saving design and improved safety features to its high-speed operation and ability to produce tightly wound coils, vertical drop coilers offer numerous benefits for manufacturers of high carbon steel wire. With their versatility and efficiency, vertical drop coilers are a valuable asset for any production facility looking to optimize their wire take-up process and improve overall productivity.