Table of Contents

Iingcebiso zokuGcina kunye nokuLungisa uMshini woMzobo weNcingo oLungileyo kwiMveliso yeKhabhoni ephantsi

Imishini yokudweba ucingo oluchanekileyo zixhobo eziyimfuneko ekuveliseni i-carbon steel wire. Aba matshini benzelwe ukutsala ucingo ngothotho lokufa ukunciphisa ubukhulu bayo nokuphucula umgangatho walo. Ukuqinisekisa ukusebenza ngokufanelekileyo koomatshini bokuzoba ngocingo oluthe tye, ukugcinwa okufanelekileyo kunye nokwenza ngcono kubalulekile. Kweli nqaku, siza kuxoxa ngeengcebiso zokugcina kunye nokwandisa oomatshini bokuzoba ngocingo olusezantsi lwemveliso yocingo lwentsimbi yekhabhoni ephantsi.

IiNzuzo zokuSebenzisa oomatshini bokuzoba beNxibelelwano yoNxibelelwano lweNtsimbi yeKhabhoni ePhantsi

Umzobo wocingo yinkqubo esetyenziselwa ukunciphisa idiameter yocingo ngokutsala ngothotho lweedies. Le nkqubo isetyenziswa ngokuqhelekileyo ekwenzeni iintlobo ezahlukeneyo zocingo, kubandakanywa ucingo lwentsimbi yekhabhoni ephantsi. Oomatshini bokuzoba ngocingo oluthe tye lukhetho oludumileyo kwesi sicelo ngenxa yokusebenza kakuhle kunye nokusebenza kwabo ekuveliseni ucingo olukumgangatho ophezulu.

Olunye lweenzuzo eziphambili zokusebenzisa umatshini wokuzoba ngocingo olusezantsi kwikhabhoni yentsimbi ephantsi kukukwazi kwabo ukuvelisa ucingo. ngedayamitha engaguqukiyo kunye nokugqiba komphezulu. Oku kubalulekile kwizicelo apho ucingo lufuna ukuhlangabezana nokunyamezela kunye neemfuno ezithile. Uyilo lomgca othe tye waba matshini uqinisekisa ukuba ucingo lutsalwa kwindawo yokufa ngendlela efanayo, nto leyo ekhokelela kwisiphelo esigudileyo nesilinganayo.

Ngaphezu kokuvelisa ucingo olukumgangatho ophezulu, oomatshini bokuzoba ngocingo oluthe tye baziwa imveliso yabo ephezulu kunye nokusebenza kakuhle. Aba matshini bayakwazi ukutsala ucingo ngesantya esiphezulu, nto leyo evumela abavelisi ukuba bavelise iingcingo ezininzi ngexesha elifutshane. Oku kunokunceda ukunciphisa iindleko zemveliso kunye nokwandisa ukusebenza kakuhle ngokubanzi kwinkqubo yokuvelisa.

Olunye uncedo lokusebenzisa oomatshini bokuzoba ngocingo lwentambo yocingo oluphantsi lwekhabhoni yentsimbi kukuguquguquka kwabo. Aba matshini bayakwazi ukudweba ucingo kuluhlu olubanzi lwee-diameters, okwenza ukuba bafaneleke kwizicelo ezahlukeneyo. Ingaba ufuna ukuvelisa ucingo olucekethekileyo kwizicelo zombane okanye ucingo oluthe kratya ngeenjongo zokwakha, umatshini wokuzoba ngocingo oluchanekileyo unokulungelelaniswa lula ukuhlangabezana neemfuno zakho ezithile.

Ngaphezu koko, oomatshini bokuzoba ngocingo oluthe tye baziwa ngokuhlala nokuthembeka. Aba matshini bakhelwe ukumelana nobunzima bokusebenza ngokuqhubekayo, nto leyo ebenza utyalo-mali oluhlala ixesha elide kubavelisi. Ngokugcinwa okufanelekileyo kunye nokunyamekela, umatshini wokudweba ucingo oluchanekileyo unokubonelela iminyaka yenkonzo ethembekileyo, inceda ukuqinisekisa ukuveliswa okuqhubekayo kocingo oluphezulu. ucingo lwentsimbi. Ukususela kumandla abo okuvelisa ucingo oluphezulu kunye nobubanzi obuhambelanayo kunye nokugqitywa kwendawo ukuya kwimveliso yabo ephezulu kunye nokusebenza kakuhle, aba matshini bayinto ebalulekileyo kwinkqubo yokuvelisa. Ukuguquguquka kwazo kunye nokuqina kwazo kuzenza zibe yinketho eguquguqukayo yoluhlu olubanzi lwezicelo, ngelixa ukuthembeka kwabo kuqinisekisa ukusebenza okuhambelanayo ngexesha. Ukuba ukwimarike yomatshini wokuzoba ngocingo olusezantsi lwekhabhoni yentsimbi, qwalasela iingenelo zokusebenzisa umatshini wokuzoba ngocingo oluchanekileyo kwiimfuno zakho zokwenza.

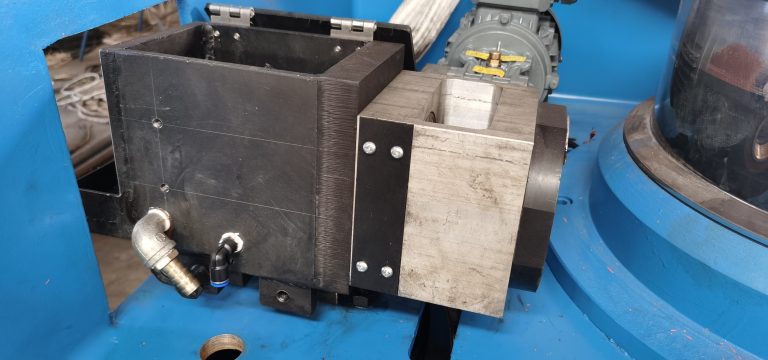

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wire, including low carbon steel wire. straight line wire drawing machines are a popular choice for this application due to their efficiency and effectiveness in producing high-quality wire.

One of the key benefits of using Straight Line Wire Drawing Machine For Low Carbon Steel Wire is their ability to produce wire with consistent diameter and surface finish. This is important in applications where the wire needs to meet specific tolerances and requirements. The straight line design of these machines ensures that the wire is pulled through the dies in a uniform manner, resulting in a smooth and even surface finish.

In addition to producing high-quality wire, straight line wire drawing machines are also known for their high productivity and efficiency. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to reduce production costs and increase overall efficiency in the manufacturing process.

Another benefit of using straight line wire drawing machines for low carbon steel wire is their versatility. These machines are capable of drawing wire in a wide range of diameters, making them suitable for a variety of applications. Whether you need to produce thin wire for electrical applications or thicker wire for construction purposes, a straight line wire drawing machine can be easily adjusted to meet your specific requirements.

Furthermore, straight line wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, making them a long-lasting investment for manufacturers. With proper maintenance and care, a straight line wire drawing machine can provide years of reliable service, helping to ensure consistent production of high-quality wire.

In conclusion, straight line wire drawing machines offer a number of benefits for manufacturers producing low carbon steel wire. From their ability to produce high-quality wire with consistent diameter and surface finish to their high productivity and efficiency, these machines are a valuable asset in the manufacturing process. Their versatility and durability make them a versatile option for a wide range of applications, while their reliability ensures consistent performance over time. If you are in the market for a wire drawing machine for low carbon steel wire, consider the benefits of using a straight line wire drawing machine for your manufacturing needs.