Table of Contents

Ukuthelekiswa kweeModeli zoomatshini bokuzoba ngocingo olwahlukileyo oluLuthekileyo

IiNgcebiso zokuLondoloza koomatshini bokuzoba ngocingo oluNto oLungileyo

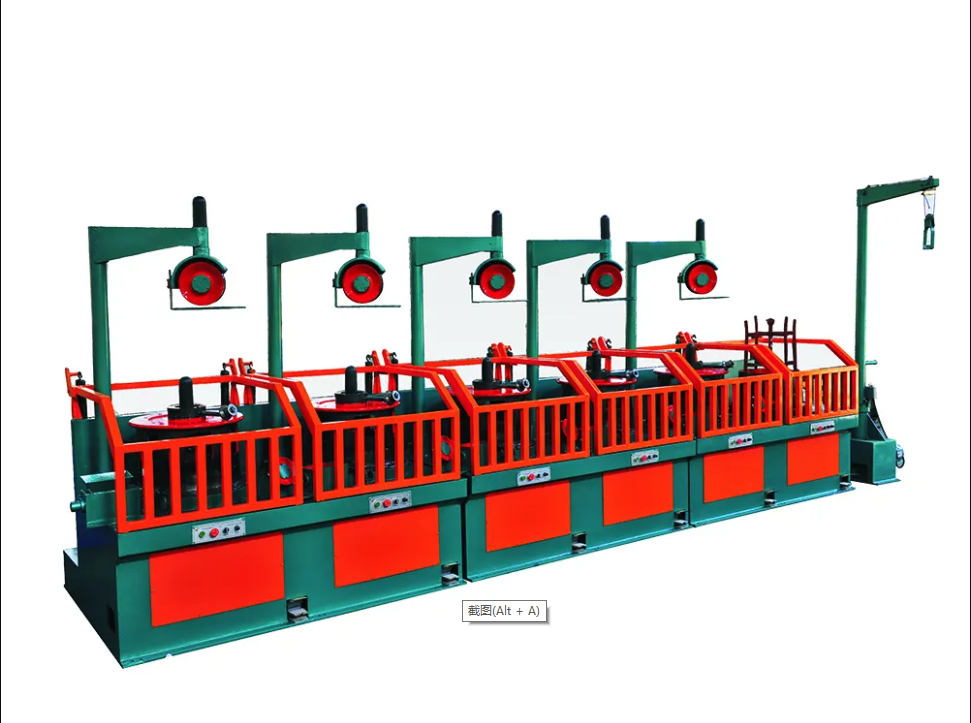

Oomatshini bokuzoba ngocingo oluchanekileyo zizixhobo ezibalulekileyo kwishishini lokuvelisa, ezisetyenziselwa ukuvelisa iingcingo ezinobubanzi obuhlukeneyo kunye nobude. Aba matshini basebenza ngokutsala ucingo kuthotho lweefa ukuze kuncitshiswe ubukhulu bayo nokuphucula umphezulu wayo. Ukuqinisekisa ukusebenza okugudileyo kunye nobomi obude bomgca othe ngqo wokuzoba umatshini wocingo lwentsimbi ephantsi, ukugcinwa rhoqo kubalulekile. Kweli nqaku, siza kuxoxa ngeengcebiso zokulungisa ukukunceda ugcine oomatshini bakho besebenza ngokufanelekileyo.

Okokugqibela, ukucwangcisa iitshekhi zokulungisa rhoqo kunye negcisa eliqeqeshiweyo kubalulekile ekugcineni oomatshini bokuzoba ngocingo oluthe ngqo bekwimeko ephezulu. Umchwephesha oqeqeshiweyo unokwenza uhlolo olunzulu ngakumbi kwaye achonge nayiphi na imiba enokuthi ingabonakali ngexesha lokugcinwa kwesiqhelo. Basenokunikezela ngeengcebiso zokuphucula ukusebenza komatshini kunye nokwandisa ubomi bawo.

Ekuqukunjelweni, ukugcinwa okufanelekileyo kubalulekile ukuze kuqinisekiswe ukusebenza kakuhle kunye nokuphila ixesha elide koomatshini bokuzoba ngocingo oluthe ngqo. Ngokulandela ezi ngcebiso zokulungisa, unokugcina oomatshini bakho besebenza kakuhle kwaye bavelise iingcingo ezikumgangatho ophezulu rhoqo. Khumbula ukucoca kunye nokuthambisa umatshini rhoqo, uhlole ukunxiba kunye nokukrazula, ukubeka iliso kwiiparamitha zokusebenza, kunye nokucwangcisa iitshekhi zokugcinwa rhoqo kunye nochwepheshe oqeqeshiweyo. Ngokhathalelo olufanelekileyo kunye nokugcinwa, oomatshini bakho bokuzoba ngocingo oluthe tye banokuqhubeka nokuhlangabezana neemfuno zakho zemveliso kwiminyaka ezayo.

straight line wire drawing machines are essential equipment in the manufacturing industry, used to produce wires of various diameters and lengths. These machines operate by pulling a wire through a series of dies to reduce its diameter and improve its surface finish. To ensure the smooth operation and longevity of Straight Line Wire Drawing Machine For Low Carbon Steel Wire, regular maintenance is crucial. In this article, we will discuss some maintenance tips to help you keep your machines running efficiently.

One of the most important maintenance tasks for straight line wire drawing machines is cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues. Pay special attention to the dies and rollers, as any buildup on these components can affect the quality of the wire being produced.

In addition to cleaning, lubrication is another key aspect of maintaining straight line wire drawing machines. Proper lubrication helps reduce friction between moving parts, preventing wear and tear and extending the machine’s lifespan. Be sure to use the recommended lubricants for each component, as using the wrong type of lubricant can cause damage. Check the lubrication levels regularly and top up as needed to ensure smooth operation.

Inspecting the machine for wear and tear is also essential for maintaining straight line wire drawing machines. Look for signs of damage or excessive wear on components such as dies, rollers, and bearings. Replace any worn or damaged parts promptly to prevent further damage to the machine and ensure consistent wire quality. Regular inspections can help identify potential issues before they escalate into major problems.

Another important maintenance tip for straight line wire drawing machines is to monitor the machine’s operating parameters. Keep an eye on factors such as wire tension, speed, and temperature to ensure they are within the recommended range. Adjust these parameters as needed to optimize the machine’s performance and prevent overheating or other issues. Regularly calibrating the machine’s settings can help maintain consistent wire quality and prevent production delays.

Lastly, scheduling regular maintenance checks with a qualified technician is crucial for keeping straight line wire drawing machines in top condition. A professional technician can perform more in-depth inspections and identify any potential issues that may not be apparent during routine maintenance. They can also provide recommendations for optimizing the machine’s performance and extending its lifespan.

In conclusion, proper maintenance is essential for ensuring the efficient operation and longevity of straight line wire drawing machines. By following these maintenance tips, you can keep your machines running smoothly and produce high-quality wires consistently. Remember to clean and lubricate the machine regularly, inspect for wear and tear, monitor operating parameters, and schedule regular maintenance checks with a qualified technician. With proper care and maintenance, your straight line wire drawing machines can continue to meet your production needs for years to come.