Table of Contents

IiNgcebiso zokuLondoloza koomatshini bokuzoba ngocingo oluNto oLungileyo

Ukuthelekiswa kweeModeli zoomatshini bokuzoba ngocingo olwahlukileyo oluLuthekileyo

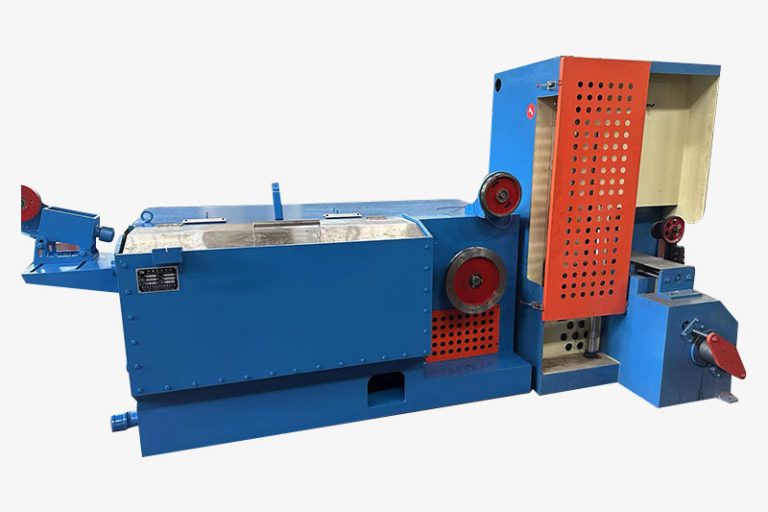

Umzobo wocingo yinkqubo esetyenziswa kushishino lwemveliso ukunciphisa ububanzi bocingo ngokutsalwa kuluhlu lweedies. Le nkqubo ibalulekile ekuveliseni iingcingo zobukhulu obahlukeneyo kunye neemilo ezisetyenziswa kuluhlu olubanzi lwezicelo, ukusuka kwiingcingo zombane ukuya kucingo. Umatshini wokuzoba ngocingo oluqhubekayo luhlobo lomatshini wokuzoba olusetyenziswa ngokuqhelekileyo kushishino ngenxa yokusebenza kakuhle kunye nokuchaneka kwawo.

Ekuqukunjelweni, oomatshini bokuzoba ngocingo oluchanekileyo sisixhobo esibalulekileyo kwishishini lokuvelisa, okuvumela iinkampani ukuba zivelise iingcingo ezinobungakanani obuhlukeneyo kunye neemilo ngokuchaneka kunye nokusebenza kakuhle. Ngokuthelekisa iimodeli ezahlukeneyo ezisekwe kwizinto ezifana nenani lokufa, isantya, umgangatho wokwakha, kunye nenqanaba lokuzenzekelayo, unokukhetha umatshini ohlangabezana neemfuno zakho ezithile kwaye uncede ufezekise iinjongo zakho zemveliso.

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. Continuous Wire Drawing Machine is a type of wire drawing machine that is commonly used in the industry due to their efficiency and precision.

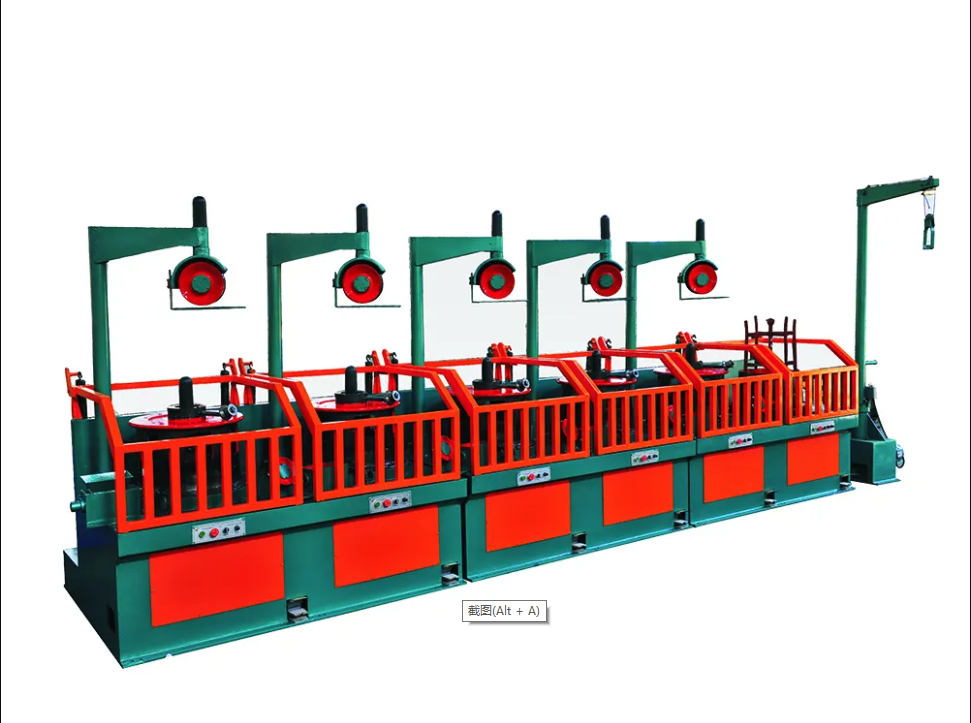

There are several different models of straight line wire drawing machines available on the market, each with its own unique features and capabilities. In this article, we will compare some of the most popular models to help you determine which one is best suited for your specific needs.

One of the most important factors to consider when choosing a straight line wire drawing machine is the number of dies it has. The number of dies determines how many times the wire will be drawn through the machine, which in turn affects the final diameter of the wire. Machines with more dies are capable of producing wires with smaller diameters, making them ideal for applications that require fine wires.

Another important factor to consider is the speed at which the machine can operate. The speed of the machine will determine how quickly you can produce wire, which can have a significant impact on your overall production efficiency. Machines with higher speeds are able to produce wire at a faster rate, making them ideal for high-volume production environments.

In addition to the number of dies and the speed of the machine, it is also important to consider the overall build quality and durability of the machine. A well-built machine will be able to withstand the rigors of daily use and provide consistent performance over time. Look for machines that are made from high-quality materials and have a solid construction to ensure long-term reliability.

When comparing different models of straight line wire drawing machines, it is also important to consider the level of automation and control that each machine offers. Some machines come equipped with advanced features such as digital controls and automatic tension adjustment, which can help improve the overall efficiency and accuracy of the wire drawing process.

Ultimately, the best straight line wire drawing machine for your needs will depend on a variety of factors, including the size of wire you need to produce, the volume of production required, and your budget. By carefully considering these factors and comparing different models, you can choose a machine that will help you achieve your production goals efficiently and effectively.

In conclusion, straight line wire drawing machines are an essential tool for the manufacturing industry, allowing companies to produce wires of various sizes and shapes with precision and efficiency. By comparing different models based on factors such as the number of dies, speed, build quality, and level of automation, you can choose a machine that meets your specific needs and helps you achieve your production goals.