Table of Contents

IiNgcebiso zokuLondoloza koomatshini bokuzoba ngocingo oluNto oLungileyo

Izinto eziluncedo zokuSebenzisa oomatshini bokuzoba ngocingo oluLungileyo

Ngaphezu koko, oomatshini bokuzoba ngocingo oluthe ngqo baziwa ngokuqina nokuthembeka. Aba matshini bakhelwe ukumelana nobunzima bokusebenza ngokuqhubekayo, okwenza kube lutyalo-mali oluhlala ixesha elide kubavelisi. Ngokulondolozwa ngokufanelekileyo kunye nokunyamekela, umatshini wokudweba ucingo oluchanekileyo unokubonelela iminyaka yenkonzo ethembekileyo, ukunceda abavelisi ukunciphisa ixesha lokunciphisa kunye nokwandisa ukusebenza kakuhle kwemveliso. ishishini lokuzoba ngocingo. Ukusuka ngokuchanekileyo kunye nemveliso ukuya kwizinto ezininzi kunye nokuqina, aba matshini babonelela ngezakhono ezifunekayo ukuvelisa ucingo olukumgangatho ophezulu kwizicelo ezininzi. Ukuba ukwimarike yomatshini wokuzoba ngocingo, cinga ngokwenza utyalo-mali kumatshini wokuzoba ngocingo oluthe tye ukuze uthathe ithuba lezi zibonelelo kwaye uphucule inkqubo yakho yokwenza.

Advantages of Using straight line wire drawing machines

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One type of Continuous Wire Drawing Machine that is commonly used in this process is the straight line wire drawing machine.

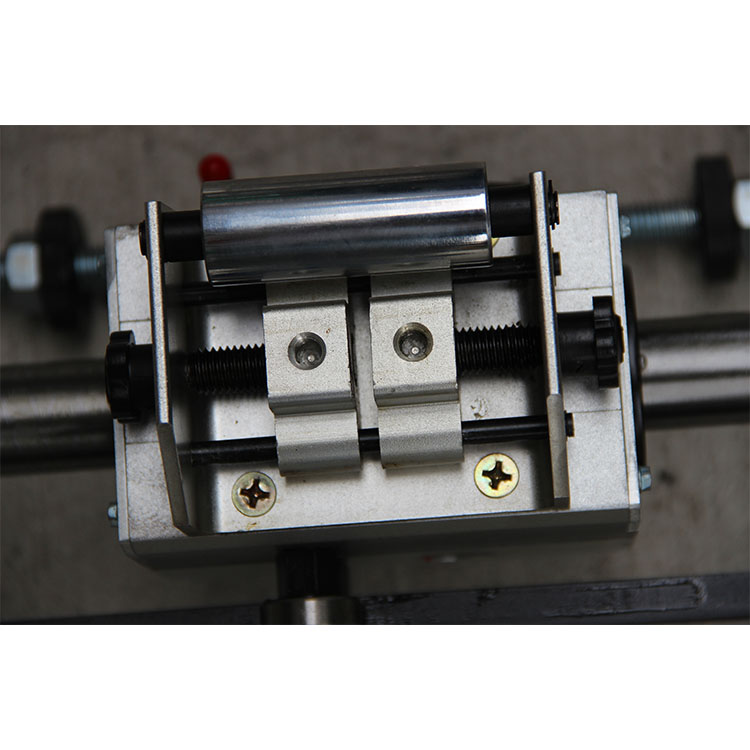

Straight line wire drawing machines are designed to pull the wire through a series of dies in a straight line, without any bending or twisting. This type of machine offers several advantages over other types of wire drawing machines, making it a popular choice for many manufacturers.

One of the main advantages of using a straight line wire drawing machine is its ability to produce wires with a high level of precision. Because the wire is pulled through the dies in a straight line, there is minimal distortion or stretching of the wire, resulting in a more uniform diameter and smoother surface finish. This level of precision is essential for applications where the wire needs to meet strict tolerances or specifications.

In addition to precision, straight line wire drawing machines also offer increased productivity. These machines are capable of drawing wire at higher speeds than other types of wire drawing machines, allowing manufacturers to produce more wire in less time. This increased productivity can help manufacturers meet tight production deadlines and keep up with high demand for their products.

Another advantage of using a straight line wire drawing machine is its versatility. These machines can be used to draw a wide range of wire sizes and materials, making them suitable for a variety of applications. Whether you need to produce thin copper wire for electrical applications or thick steel wire for industrial purposes, a straight line wire drawing machine can handle the job.

Furthermore, straight line wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, making them a long-lasting investment for manufacturers. With proper maintenance and care, a straight line wire drawing machine can provide years of reliable service, helping manufacturers reduce downtime and increase production efficiency.

In conclusion, straight line wire drawing machines offer several advantages that make them a popular choice for manufacturers in the wire drawing industry. From precision and productivity to versatility and durability, these machines provide the capabilities needed to produce high-quality wire for a wide range of applications. If you are in the market for a wire drawing machine, consider investing in a straight line wire drawing machine to take advantage of these benefits and improve your manufacturing process.