Enye yeenzuzo eziphambili zokusebenzisa umatshini wokudweba ucingo oluchanekileyo kwi-carbon steel wire ephantsi kukukwazi ukuvelisa ucingo oluphezulu kunye nobubanzi obuhambelanayo kunye nokugqitywa kwendawo. Uyilo lomgca ochanekileyo womatshini uqinisekisa ukuba ucingo lutsalwa ngokufa ngendlela echanekileyo kunye nefanayo, okubangelwa ucingo olungenaziphene kunye nokungafezeki. Oku kubalulekile kwizicelo apho ucingo lufuna ukuhlangabezana nemigangatho engqongqo yobulunga.

Olunye uncedo lokusebenzisa umatshini wokuzoba ngocingo oluchanekileyo kukusebenza kwawo kunye nemveliso. Aba matshini benzelwe ukusebenza ngesantya esiphezulu, nto leyo evumela abavelisi ukuba bavelise iingcingo ezininzi ngexeshana elifutshane. Oku kunokunceda ukunciphisa iindleko zemveliso kunye nokunyusa imveliso ngokubanzi. Ukongezelela, umgca ochanekileyo woyilo lomatshini unciphisa ixesha lokunciphisa kunye nokugcinwa, ukuqhubela phambili ukuphucula imveliso.

Ngaphezu komgangatho wayo ophezulu kunye nokusebenza kakuhle, umatshini wokudweba ucingo oluchanekileyo unikezela ngeendlela ezahlukeneyo ngokubhekiselele kwi-diameter ye-wire kunye nempahla. Aba matshini banokuhlengahlengiswa ngokulula ukulungiselela ubungakanani beengcingo ezahlukeneyo kunye neentlobo, ezibenza bafaneleke kuluhlu olubanzi lwezicelo. Oku kuguquguquka kuvumela abavelisi ukuba bavelise iintlobo zeemveliso zocingo ngaphandle kwesidingo soomatshini abaninzi.

Ngaphezu koko, oomatshini bokuzoba ngocingo oluthe ngqo baziwa ngokuhlala kunye nokuthembeka. Aba matshini bakhelwe ukumelana nobunzima bokusebenza ngokuqhubekayo kunye nokusetyenziswa kakhulu, ukuqinisekisa ukuba banokusebenza ngokuthembekileyo kwiminyaka ezayo. Oku kunokunceda ukunciphisa ixesha lokuphumla kunye neendleko zokugcina, ukuphucula ngakumbi ukusebenza kakuhle kwenkqubo yokuvelisa.

Ngokupheleleyo, izibonelelo zokusebenzisa umatshini wokudweba ucingo oluchanekileyo kwi-carbon steel wire ephantsi icacile. Ukusuka kwimveliso yocingo oluphezulu ukuya konyuka kobuchule kunye nemveliso, aba matshini banika uluhlu lweenzuzo ezibenza babe lutyalo-mali oluxabisekileyo kubavelisi. Ngokuguquguquka, ukuqina, kunye nokuthembeka, oomatshini bokuzoba ngocingo oluthe tye sisixhobo esibalulekileyo kuye nawuphi na umenzi ojonge ukuvelisa iimveliso zocingo ezikumgangatho ophezulu.

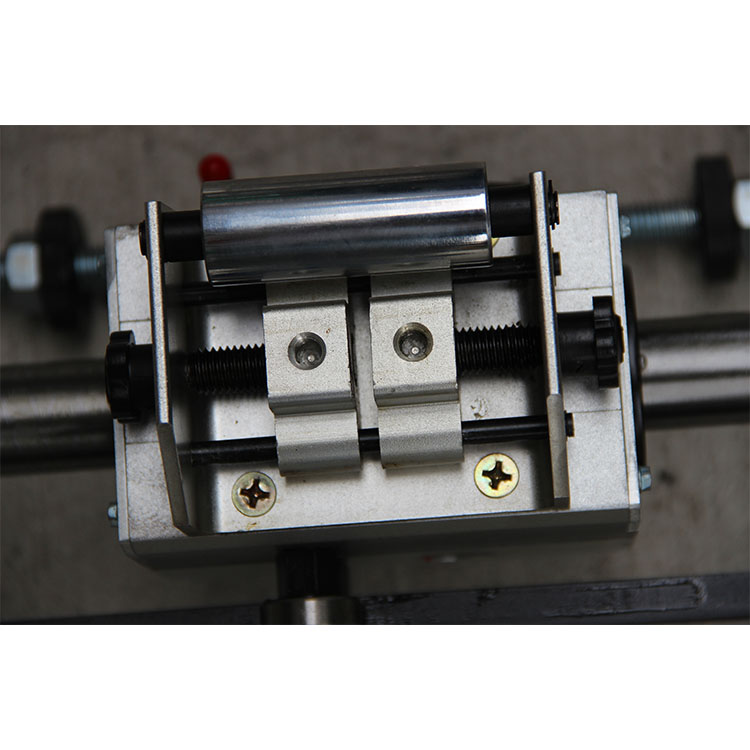

One of the main benefits of using a straight line wire drawing machine For Low Carbon Steel Wire is its ability to produce high-quality wire with consistent diameter and surface finish. The straight line design of the machine ensures that the wire is pulled through the dies in a straight and uniform manner, resulting in a wire that is free from defects and imperfections. This is important for applications where the wire needs to meet strict quality standards.

Another benefit of using a straight line wire drawing machine is its efficiency and productivity. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to reduce production costs and increase overall output. Additionally, the straight line design of the machine minimizes downtime and maintenance, further improving productivity.

In addition to its high quality and efficiency, a straight line wire drawing machine offers versatility in terms of wire diameter and material. These machines can be easily adjusted to accommodate different wire sizes and types, making them suitable for a wide range of applications. This flexibility allows manufacturers to produce a variety of wire products without the need for multiple machines.

Furthermore, straight line wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation and heavy use, ensuring that they can perform reliably for years to come. This can help to minimize downtime and maintenance costs, further improving the overall efficiency of the manufacturing process.

Overall, the benefits of using a straight line wire drawing machine for low carbon steel wire are clear. From high-quality wire production to increased efficiency and productivity, these machines offer a range of advantages that make them a valuable investment for manufacturers. With their versatility, durability, and reliability, straight line wire drawing machines are an essential tool for any manufacturer looking to produce high-quality wire products.