Table of Contents

Ukuphonononga iiNzuzo zokusebenzisa isixhobo sokususa ibhrashi yocingo yentsimbi yokususa umhlwa

Ekuqukumbeleni, i-steel wire brush decalers inika uluhlu lweenzuzo zokususa i-rust. Ukusuka ekusebenzeni kwazo kunye nokuguquguquka kwazo ukuya ekomeleleni kwazo kunye nokulula kokusetyenziswa, ezi brashi sisixhobo esibalulekileyo kuye nabani na ojongene nomhlwa. Nokuba ungumrhwebi oqeqeshiweyo okanye ungumntu othanda izinto zokuzilibazisa osebenza kwiprojekthi ekhaya, isixhobo sokususa ibrashi yocingo lwentsimbi sinokukunceda ukuba ufezekise ukugqibezela okucocekileyo nokupholisiweyo kumphezulu wesinyithi. Cinga ukongeza enye yezi brashi kwisixhobo sakho namhlanje kwaye ufumane izibonelelo zakho.

Indlela yokugcinwa ngokufanelekileyo kunye nokuCoca iBrashi yeBrashi yocingo yeNsimbi yentsimbi

Ukongezelela ekuhloleni ama-bristles, kubalulekile ukujonga umqheba we-steel wire brush descaler naziphi na iimpawu zokugqoka okanye umonakalo. Isiphatho esixekethileyo okanye esonakeleyo sinokwenza isixhobo sibe nzima ukusisebenzisa kwaye sinokubeka ingozi yokhuseleko. Ukuba ubona nayiphi na imiba ngesiphatho, kungcono ukusibuyisela ngokukhawuleza kangangoko kunokwenzeka.

Ukucoca isixhobo sakho sokususa ibrashi yocingo lwentsimbi, qala ngokususa nabuphi na ubudoti okanye i-buildup kwiibristles. Ungakwenza oku ngokusebenzisa ikama yebrashi yocingo okanye ibrashi eqinileyo ukususa nabuphi na ubumdaka okanye inkunkuma enokuthi ibambeke kwiibristles. Qinisekisa ukuba unxibe iiglavu kunye nokukhuselwa kwamehlo ngelixa ucoca ibhrashi ukuthintela ukwenzakala.

Wakuba ususe nayiphi na inkunkuma kwiibristles, unokucoca ibhrashi ngesicoci esincinci kunye namanzi ashushu. Sebenzisa ibhrashi okanye ilaphu ukukhuhla iibristles kunye nomqheba wesixhobo, uqinisekise ukuba ususa nabuphi na ubumdaka okanye ubumdaka obunokubakho. Hlamba ibhrashi ngocoselelo ngamanzi acocekileyo kwaye uyivumele yome ngokupheleleyo phambi kokuba uyisebenzise kwakhona.

Kubalulekile nokugcina kakuhle isixhobo sakho sokususa ibrashi yocingo xa singasetyenziswa. Gcina isixhobo kwindawo eyomileyo, ecocekileyo kude nokufuma kunye nokufuma ukuthintela umhlwa kunye nokuhlwa. Unako kwakhona ukuxhoma ibhrashi kwi hook okanye isikhonkwane ukuyigcina kude emhlabeni kwaye uthintele umonakalo kwibristles.

Ngaphezu kokugcinwa rhoqo kunye nokucoca, kubalulekile ukusebenzisa isixhobo sakho sokucoca ucingo lwentsimbi ngokufanelekileyo ukuqinisekisa ukuba luhlala ixesha elide. Gwema ukusebenzisa amandla amaninzi xa usebenzisa isixhobo, njengoko oku kunokubangela umonakalo kwi-bristles kunye nokusingatha. Endaweni yoko, vumela ubunzima besixhobo benze umsebenzi kwaye usebenzise uxinzelelo oluthambileyo ukususa inkunkuma kumphezulu wesinyithi.

Ngokulandela ezi ngcebiso zokugcina kunye nokucoca isixhobo sakho sokususa ibrashi yentsimbi, unokuqinisekisa ukuba isixhobo sakho sihlala sisebenza kwaye sikwimeko entle. kwiminyaka ezayo. Ukuhlolwa rhoqo, ukucocwa, kunye nokugcinwa ngokufanelekileyo ngundoqo ekugcineni ibrashi yakho yentsimbi yentsimbi ikwimo ephezulu. Ngokhathalelo olufanelekileyo, isixhobo sakho sokususa ibrashi yentsimbi siya kuqhubeka sisisixhobo esixabisekileyo sokususa umhlwa, ipeyinti, kunye nobunye ubumdaka obuvela kumphezulu wentsimbi.

How to Properly Maintain and Clean Steel Wire Brush Descaler

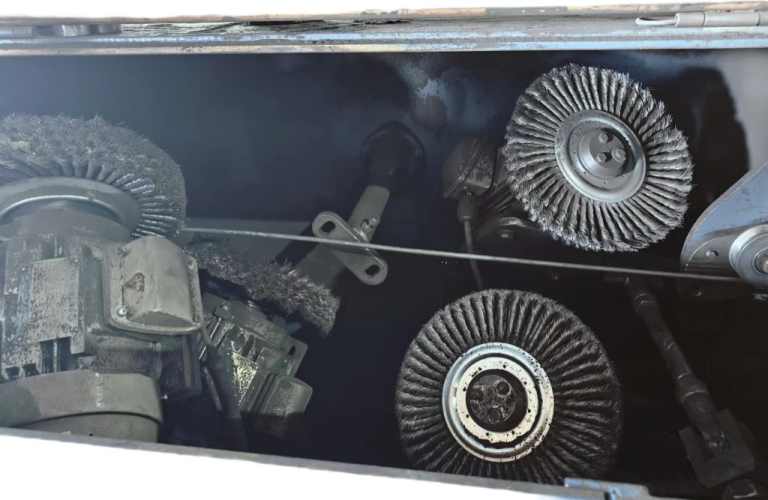

Steel Brush Descaler for Wire Drawing Process are essential tools for removing rust, paint, and other debris from metal surfaces. To ensure that your steel wire brush descaler remains effective and in good condition, proper maintenance and cleaning are crucial. In this article, we will discuss the steps you can take to properly maintain and clean your steel wire brush descaler.

One of the most important aspects of maintaining a steel wire brush descaler is to regularly inspect the tool for any signs of wear or damage. Check the bristles of the brush for any signs of fraying or breakage, as this can affect the tool’s performance. If you notice any damage, it is important to replace the brush immediately to prevent further damage to the surface you are working on.

In addition to inspecting the bristles, it is also important to check the handle of the steel wire brush descaler for any signs of wear or damage. A loose or damaged handle can make the tool difficult to use and can also pose a safety hazard. If you notice any issues with the handle, it is best to replace it as soon as possible.

To clean your steel wire brush descaler, start by removing any debris or buildup from the bristles. You can do this by using a wire brush comb or a stiff brush to remove any dirt or debris that may be stuck in the bristles. Be sure to wear gloves and eye protection while cleaning the brush to prevent injury.

Once you have removed any debris from the bristles, you can clean the brush with a mild detergent and warm water. Use a brush or cloth to scrub the bristles and handle of the tool, making sure to remove any dirt or grime that may be present. Rinse the brush thoroughly with clean water and allow it to dry completely before using it again.

It is also important to properly store your steel wire brush descaler when it is not in use. Store the tool in a dry, clean area away from moisture and humidity to prevent rust and corrosion. You can also hang the brush on a hook or peg to keep it off the ground and prevent damage to the bristles.

In addition to regular maintenance and cleaning, it is important to use your steel wire brush descaler properly to ensure its longevity. Avoid using excessive force when using the tool, as this can cause damage to the bristles and handle. Instead, let the weight of the tool do the work and use gentle pressure to remove debris from metal surfaces.

By following these tips for maintaining and cleaning your steel wire brush descaler, you can ensure that your tool remains effective and in good condition for years to come. Regular inspection, cleaning, and proper storage are key to keeping your steel wire brush descaler in top shape. With proper care, your steel wire brush descaler will continue to be a valuable tool for removing rust, paint, and other debris from metal surfaces.