Ukuthelekiswa kweendidi ezahlukeneyo ze-nbsp kunye ne-nbsp;Isicali seeNcingo zoomatshini Ngeeyunithi zokubrasha ngocingo

Olunye uhlobo kunye ne-nbsp;

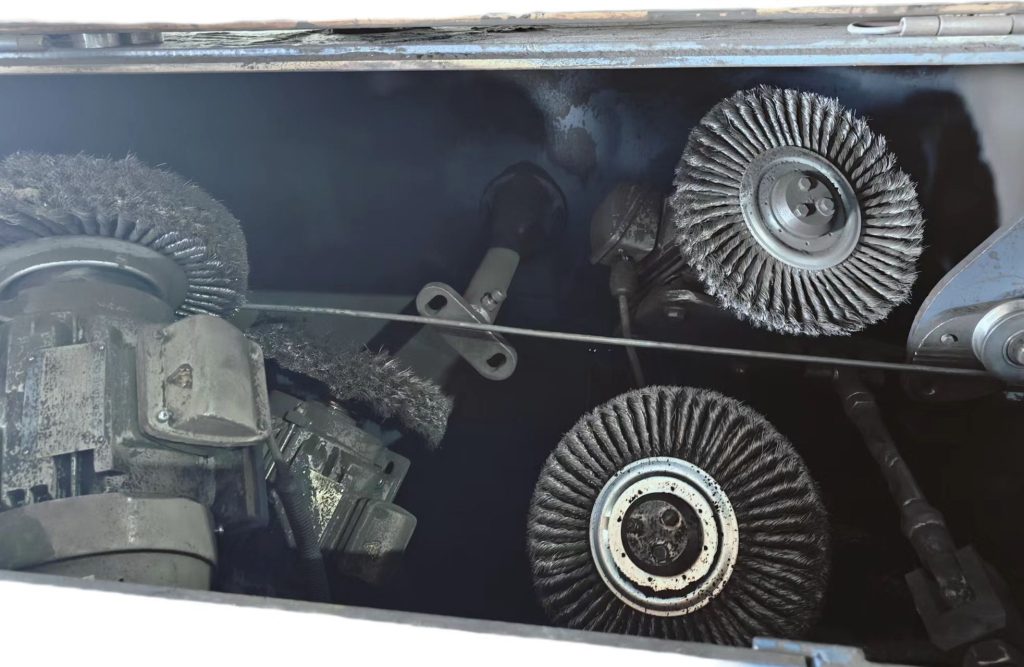

Isikali seBrashi yentsimbi yeNkqubo yoMzobo wocingo

Ekuqukunjelweni, i-mechanical wire decalers kunye neeyunithi zokuxubha ucingo zizixhobo ezibalulekileyo zokuphucula umgangatho weendawo zocingo kumashishini ahlukeneyo. Ngokuthelekisa iintlobo ezahlukeneyo zee-decalers zocingo, unokukhetha umatshini ochanekileyo kwiimfuno zakho ezithile. Nokuba ufuna i-rotary wire brush descaler, i-roller descaler, okanye i-abrasive wire brushing unit, kukho umatshini okhoyo ukuhlangabezana neemfuno zakho. Tyala imali kwisixhobo sokucoca ucingo ngeyunithi yokubrasha ngocingo namhlanje ukonyusa umgangatho weemveliso zocingo lwakho kunye nokuphucula ukusebenza kakuhle kwemveliso.Steel Brush Descaler for Wire Drawing Process unit is the roller descaler. This machine features a series of rollers that press against the wire, removing scale and other contaminants. The wire is fed through the machine, where it passes between the rollers, which clean the wire surface. Roller descalers are ideal for high-volume production environments and can handle a wide range of wire sizes.

In addition to rotary and roller descalers, there are also abrasive wire brushing units that can be used in conjunction with Mechanical Wire Descalers. These units feature abrasive wire brushes that effectively remove scale and other contaminants from the wire surface. The wire is fed through the machine, where it comes into contact with the abrasive brushes, which clean the wire as it passes through. Abrasive wire brushing units are ideal for removing tough scale and rust from wire surfaces.

When choosing a mechanical wire descaler with a wire brushing unit, it is essential to consider factors such as wire diameter, production volume, and the type of contaminants being removed. Rotary wire brush descalers are suitable for a wide range of wire sizes and are ideal for applications where a high level of cleaning is required. Roller descalers are best suited for high-volume production environments and can handle a wide range of wire sizes. Abrasive wire brushing units are ideal for removing tough scale and rust from wire surfaces and are suitable for applications where a more aggressive cleaning method is needed.

In conclusion, mechanical wire descalers with wire brushing units are essential tools for improving the quality of wire surfaces in various industries. By comparing different types of mechanical wire descalers, you can choose the right machine for your specific needs. Whether you need a rotary wire brush descaler, a roller descaler, or an abrasive wire brushing unit, there is a machine available to meet your requirements. Invest in a mechanical wire descaler with a wire brushing unit today to enhance the quality of your wire products and improve overall production efficiency.