Table of Contents

Jonga iiNzuzo zokuSebenzisa uMatshini weNgxowa-mali oNcinciweyo

IiNgcebiso zokuLondoloza koomatshini abaNcinci abaNcinci abaCwangcisiweyo

Ngaphezu koko, abaqhubi kufuneka bagcine ilog eneenkcukacha zolondolozo ezirekhoda lonke uhlolo, ulungiso nokutshintshwa. Le log isebenza njengesalathiso esibalulekileyo sokulandelela ukusebenza komatshini ekuhambeni kwexesha kwaye inokunceda ukuchonga imiba eqhubekayo enokufuna ingqalelo engaphezulu. Ngokugcina iirekhodi ezichanekileyo, abaqhubi banokuqinisekisa ukuthotyelwa kwemigaqo yokhuseleko kunye nemigangatho yoshishino.

Okokugqibela, uqeqesho kunye nemfundo yabaqhubi zizinto ezibalulekileyo zokugcinwa okusebenzayo. Ukuqinisekisa ukuba bonke abasebenzi banolwazi malunga nokusebenza kunye neemfuno zokugcinwa komatshini kunokunciphisa kakhulu ukubakho kweempazamo kunye neengozi. Iiseshoni zoqeqesho rhoqo zinokunceda ukuqinisa izenzo ezingcono kunye nokugcina abaqhubi benolwazi malunga naluphi na uhlaziyo okanye utshintsho kwiinkqubo zokulondoloza.

Ekuqukumbeleni, ukugcina oomatshini bokucoca i-staple wire kufuna indlela ebanzi equka ukuhlolwa rhoqo, ukuthambisa, ukucocwa, ukutshekishwa kombane, kunye nokuqeqeshwa komsebenzisi. . Ngokuthobela la macebiso olondolozo, abaqhubi banokuphucula ukusebenza kunye nokuphila ixesha elide koomatshini babo, ekugqibeleni babe negalelo ekwandeni kwemveliso kunye nokunciphisa iindleko zokusebenza.

Maintenance Tips for staple wire flattening machines

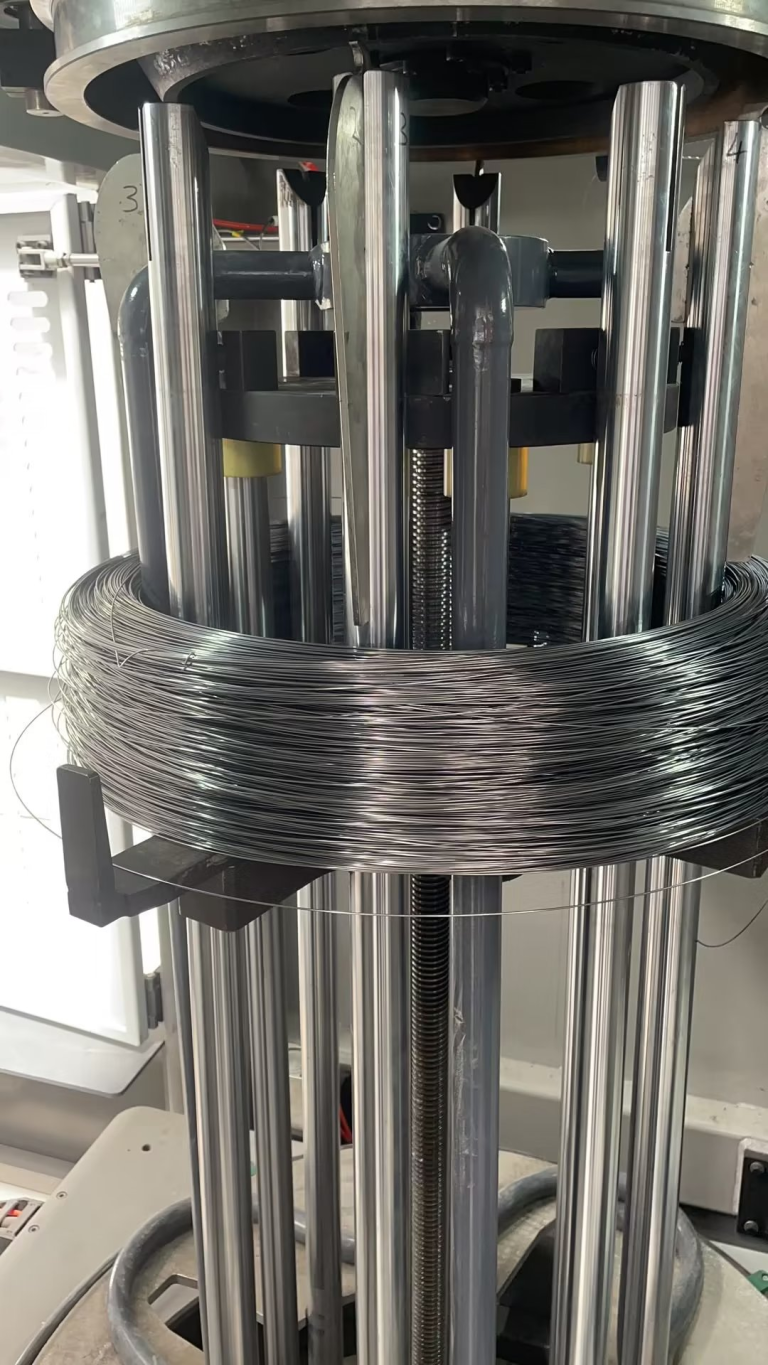

Maintaining staple wire flattening machine is essential for ensuring their longevity and optimal performance. These machines play a crucial role in the production of staple wire, which is widely used in various industries, including construction, packaging, and manufacturing. To keep these machines operating efficiently, it is important to implement a regular maintenance routine that addresses both mechanical and operational aspects.

First and foremost, regular inspection of the machine is vital. Operators should conduct daily checks to identify any signs of wear or damage. This includes examining the flattening rollers, which are critical components that directly affect the quality of the flattened wire. Any irregularities, such as uneven surfaces or excessive wear, should be addressed immediately to prevent further damage. Additionally, it is advisable to inspect the alignment of the rollers, as misalignment can lead to inconsistent flattening and increased strain on the machine.

In conjunction with inspections, lubrication is another key aspect of maintenance. Proper lubrication of moving parts reduces friction and wear, thereby extending the life of the machine. It is important to follow the manufacturer’s guidelines regarding the type and frequency of lubrication. Typically, a high-quality lubricant should be applied to bearings, gears, and other moving components at regular intervals. Furthermore, operators should ensure that any excess lubricant is wiped away to prevent accumulation of debris, which can lead to operational issues.

Moreover, cleaning the machine is an essential maintenance task that should not be overlooked. Dust, debris, and metal shavings can accumulate over time, potentially affecting the machine’s performance. Regular cleaning helps to maintain a safe working environment and ensures that the machine operates at peak efficiency. Operators should use appropriate cleaning agents and tools to remove contaminants without damaging sensitive components. It is also advisable to pay special attention to the areas around the flattening rollers, as these are prone to buildup.

In addition to these routine tasks, it is important to keep an eye on the electrical components of the machine. Regularly checking the wiring and connections can help prevent electrical failures that may lead to costly downtime. Operators should look for signs of fraying or damage to wires and ensure that all connections are secure. If any electrical issues are detected, it is crucial to address them promptly, either by consulting the machine’s manual or seeking assistance from a qualified technician.

Furthermore, operators should maintain a detailed maintenance log that records all inspections, repairs, and replacements. This log serves as a valuable reference for tracking the machine’s performance over time and can help identify recurring issues that may require further attention. By keeping accurate records, operators can also ensure compliance with safety regulations and industry standards.

Lastly, training and education for operators are essential components of effective maintenance. Ensuring that all personnel are knowledgeable about the machine’s operation and maintenance requirements can significantly reduce the likelihood of errors and accidents. Regular training sessions can help reinforce best practices and keep operators informed about any updates or changes in maintenance procedures.

In conclusion, maintaining staple wire flattening machines requires a comprehensive approach that includes regular inspections, lubrication, cleaning, electrical checks, and operator training. By adhering to these maintenance tips, operators can enhance the performance and longevity of their machines, ultimately contributing to increased productivity and reduced operational costs.