Table of Contents

Izinto eziluncedo kwi-Rolling Ring Traverse Drive kwi-Industrial Applications

Indlela yokugcinwa ngokufanelekileyo kunye nokuXubungula i-Rolling Ring Traverse Drives

Ukuba i-rolling ring traverse drive yenza ingxolo engaqhelekanga okanye ii-vibrations, oko kunokubonisa ingxaki ngamacandelo okuqhuba. Hlola amabhanti okuqhuba, iipuli, kunye neebheringi kuzo naziphi na iimpawu zokuguga okanye umonakalo kwaye ubuyisele naziphi na izinto ezigugileyo ukuze uphelise ingxolo okanye ukungcangcazela. ixesha lokuphumla elineendleko. Ukuthanjiswa rhoqo, ukuhlolwa kwamacandelo okuqhuba, ukunyanzeliswa okufanelekileyo kwamabhanti okuqhuba, kunye nokucombulula iingxaki kwimiba eqhelekileyo ngamanyathelo aphambili ekugcineni i-rolling ring traverse drives. Ngokulandela ezi zenzo zogcino, unokwandisa ixesha lokuphila kwiringi yakho yokujikeleza kunye nokuqinisekisa ukusebenza okuthembekileyo kwizicelo zakho zemizi-mveliso.

How to Properly Maintain and Troubleshoot Rolling Ring Traverse Drives

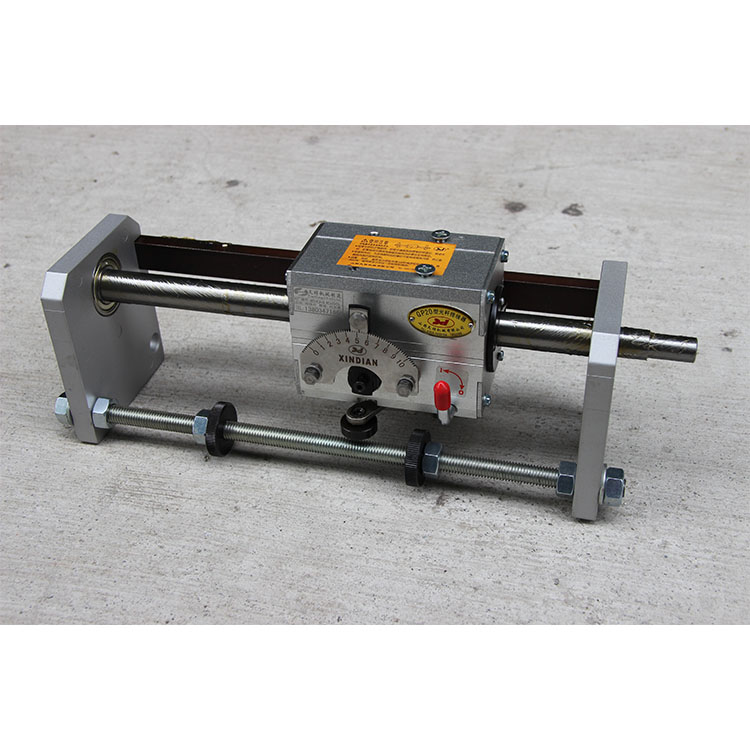

Rolling ring traverse drives are a critical component in many industrial applications, providing precise control over the movement of materials along a linear path. These drives are commonly used in industries such as textiles, wire and cable manufacturing, and packaging. Proper maintenance and troubleshooting of rolling ring traverse drives are essential to ensure smooth operation and prevent costly downtime.

One of the most important aspects of maintaining rolling ring traverse drives is regular lubrication. Proper lubrication helps reduce friction and wear on the drive components, extending their lifespan and ensuring smooth operation. It is important to use the correct type of lubricant recommended by the drive manufacturer and to follow the recommended lubrication schedule.

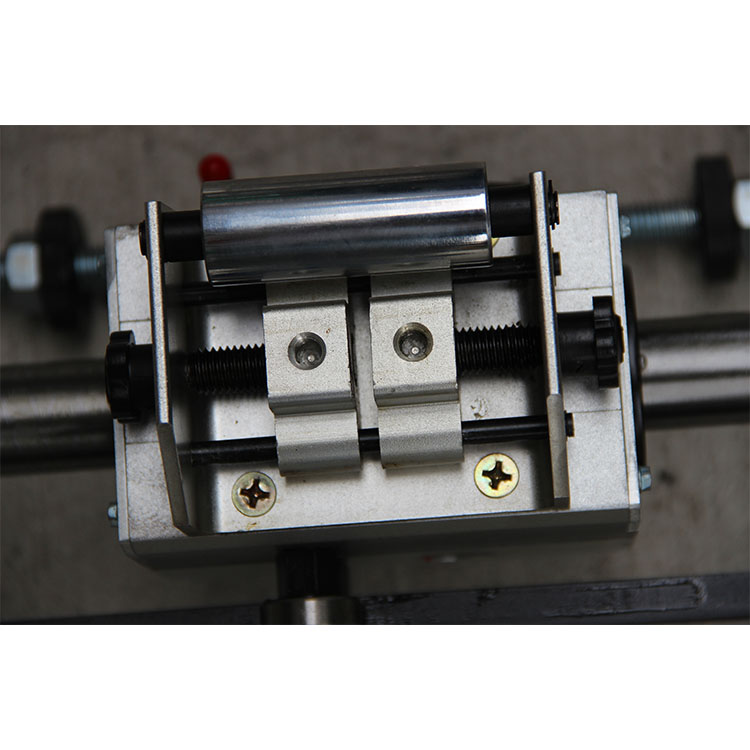

In addition to lubrication, regular inspection of the drive components is essential for detecting any signs of wear or damage. Inspect the drive belts, pulleys, and bearings for any signs of wear, such as cracks, fraying, or excessive play. Replace any worn or damaged components immediately to prevent further damage to the drive system.

Another important aspect of maintaining rolling ring traverse drives is proper tensioning of the drive belts. Over time, drive belts can stretch and lose tension, affecting the drive’s performance. Check the tension of the drive belts regularly and adjust as needed to ensure proper operation.

In the event of a malfunction or breakdown of the rolling ring traverse drive, troubleshooting is necessary to identify the root cause of the issue. One common issue with rolling ring traverse drives is misalignment of the drive components. Misalignment can cause excessive wear on the drive components and lead to premature failure. Check the alignment of the drive belts, pulleys, and bearings and make any necessary adjustments to correct the misalignment.

Another common issue with rolling ring traverse drives is belt slippage. Belt slippage can occur due to improper tensioning of the drive belts or worn drive components. Check the tension of the drive belts and replace any worn components to prevent belt slippage.

If the rolling ring traverse drive is making unusual noises or vibrations, it may indicate a problem with the drive components. Inspect the drive belts, pulleys, and bearings for any signs of wear or damage and replace any worn components to eliminate the noise or vibration.

In conclusion, proper maintenance and troubleshooting of rolling ring traverse drives are essential to ensure smooth operation and prevent costly downtime. Regular lubrication, inspection of drive components, proper tensioning of drive belts, and troubleshooting of common issues are key steps in maintaining rolling ring traverse drives. By following these maintenance practices, you can extend the lifespan of your rolling ring traverse drive and ensure reliable performance in your industrial applications.