Table of Contents

Indlela yokukhetha umatshini wokugoba oLungileyo obuyiselwe umva kwiimfuno zakho

Iingcebiso zokuGcinwa koMshini wokuBuyisa uBuyiselo kwiMeko ePhezulu

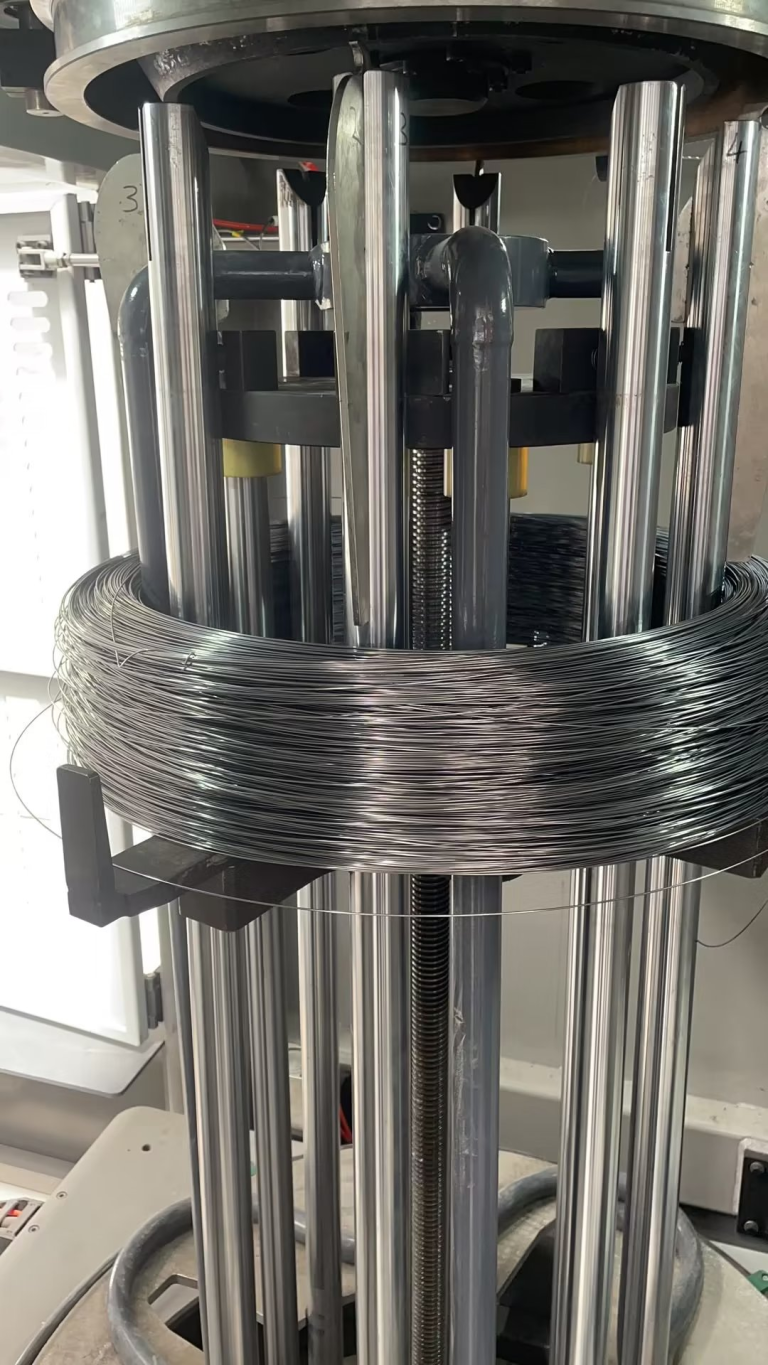

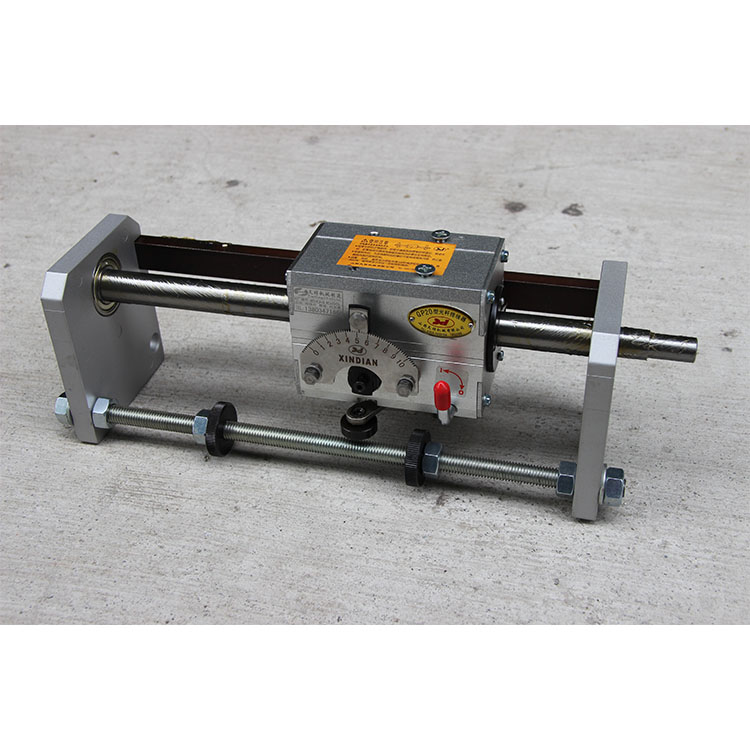

Ukugcina izixhobo zemizi-mveliso kubalulekile ekuqinisekiseni ukusebenza ngokugqibeleleyo kunye nokuphila ixesha elide. Esinye isixhobo esinjalo esifuna ukulungiswa rhoqo ngumatshini wokuthoba ugoba. Lo matshini usetyenziswa kwishishini lensimbi ukususa isikali kunye nokungcola kwiindawo zetsimbi, ukuqinisekisa ukugqiba okugudileyo nokucocekileyo. Ukugcina umatshini wakho wokuthoba intonga egobileyo ukwimeko ephezulu, landela la macebiso olondolozo.

Okokugqibela, qwalasela ukucwangcisa ukuhlolwa rhoqo kunye nokutshekishwa kokugcinwa kwegcisa eliqeqeshiweyo. Ukuhlolwa kobuchwephesha kunokunceda ukuchonga imiba enokubakho kwangethuba kwaye kuthintele ukulungiswa kweendleko ezantsi kumgca. Igcisa linokubonelela ngezimvo ezixabisekileyo kunye neengcebiso zokuphucula ukusebenza komatshini kunye nempumelelo.

Ekuqukunjelweni, ukugcina umatshini wakho wokugoba obuyiselwe umva kubalulekile ekuqinisekiseni ukusebenza ngokugqibeleleyo kunye nokuphila ixesha elide. Ngokulandela ezi ngcebiso zokugcina, unokugcina umatshini wakho ukwimeko ephezulu kwaye uthintele ukophuka kweendleko. Ukuhlolwa rhoqo, ukucocwa, ukulinganisa, kunye nokulandela izikhokelo zomenzi ngundoqo ekugcineni umatshini wakho usebenza kakuhle. Ukongeza, ukucwangcisa rhoqo ukugcinwa kweetshekhi nguchwepheshe oqeqeshiweyo kunokunceda ukuchonga nokujongana nayo nayiphi na imiba ngaphambi kokuba inyuke. Ngokukhathalela umatshini wakho wokugoba obuyiselwe umva, unokuqinisekisa ukuba uyaqhubeka nokusebenza ngokufanelekileyo nangempumelelo kwiminyaka ezayo.

Maintaining industrial equipment is crucial for ensuring optimal performance and longevity. One such piece of equipment that requires regular maintenance is the reversed bending descaling machine. This machine is used in the steel industry to remove scale and impurities from metal surfaces, ensuring a smooth and clean finish. To keep your reversed bending Wire Rod Descaling Machine in top condition, follow these maintenance tips.

First and foremost, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, chains, and bearings. Replace any worn-out components immediately to prevent further damage to the machine. Additionally, lubricate moving parts regularly to reduce friction and extend the lifespan of the machine.

Another important maintenance tip is to clean the machine regularly. Dust, dirt, and debris can accumulate on the machine’s surfaces and components, leading to decreased efficiency and potential breakdowns. Use a soft brush or cloth to remove any buildup and ensure that the machine is clean and free of obstructions.

In addition to cleaning, it is crucial to inspect the machine’s cooling system regularly. Overheating can cause serious damage to the machine’s components and reduce its efficiency. Check the coolant levels and ensure that the cooling system is functioning correctly. If you notice any issues, such as leaks or blockages, address them immediately to prevent overheating and potential damage to the machine.

Furthermore, it is essential to calibrate the machine regularly to ensure accurate and consistent performance. Check the machine’s settings and adjust them as needed to meet the desired specifications. This will help maintain the quality of the descaling process and prevent issues such as uneven descaling or surface damage.

Additionally, it is crucial to follow the manufacturer’s guidelines for maintenance and operation. Familiarize yourself with the machine’s manual and recommended maintenance schedule. Adhering to these guidelines will help prevent premature wear and tear and ensure that the machine operates at its best.

Lastly, consider scheduling regular inspections and maintenance checks by a qualified technician. A professional inspection can help identify potential issues early on and prevent costly repairs down the line. A technician can also provide valuable insights and recommendations for optimizing the machine’s performance and efficiency.

In conclusion, maintaining your reversed bending descaling machine is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your machine in top condition and prevent costly breakdowns. Regular inspections, cleaning, calibration, and following manufacturer guidelines are key to keeping your machine running smoothly. Additionally, scheduling regular maintenance checks by a qualified technician can help identify and address any issues before they escalate. By taking care of your reversed bending descaling machine, you can ensure that it continues to operate efficiently and effectively for years to come.