Table of Contents

Ukusebenzisa uMatshini wokuBuyisa ukugoba kwiZicelo zeShishini

Kwizicelo zemizi-mveliso, inkqubo yokwehla ibalulekile ekugcineni ukusebenza kakuhle kunye nokuphila ixesha elide kwezixhobo. Ukunciphisa kubandakanya ukususa isikali, umhlwa, kunye nobunye ukungcola kwimigangatho yesinyithi ukuthintela ukubola kunye nokuphucula ukusebenza. Enye indlela esebenzayo yokwehla kusetyenziso lomatshini wokuthoba umva wokugoba.

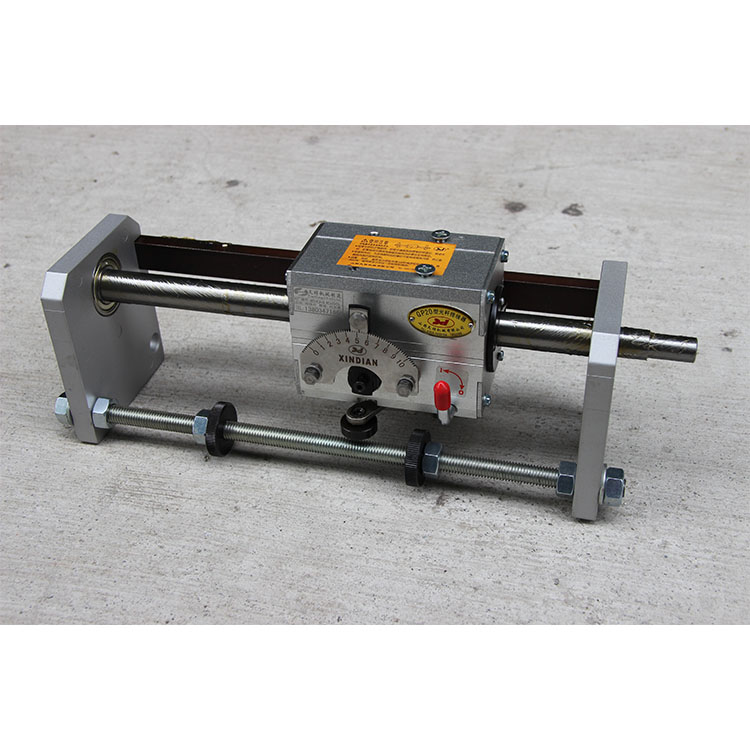

Isikali sokugoba esibuyiselwe umva kwinkqubo yokulungiselela umzobo wocingo sisixhobo esikhethekileyo esiyilelwe ukususa ngokufanelekileyo nangokufanelekileyo isikali kumphezulu wesinyithi. Lo matshini usebenzisa uluhlu lweerola kunye neebhrashi ukugoba isinyithi kwelinye icala, okubangela ukuba isikali siqhekeke kwaye siqhawuke. Emva koko isinyithi silungelelaniswa, sishiya ngasemva indawo ecocekileyo negudileyo.

Enye yeenzuzo eziphambili zokusebenzisa umatshini wokuthoba ukugoba oguqulweyo kukukwazi ukususa isikali ngokukhawuleza nangokufanelekileyo. Iindlela eziqhelekileyo zokunciphisa zingadla ixesha kunye nomsebenzi omkhulu, zifuna umsebenzi wezandla kunye neekhemikhali ezibukhali. Ngokwahlukileyo, umatshini wokuthoba ukugoba obuyiselweyo unokuhlahlela iindawo zetsimbi kwiqhezu lexesha, ukonga zombini ixesha kunye neendleko zabasebenzi.

Olunye uncedo lokusebenzisa umatshini wokugoba oguqulweyo kukukwazi ukuthoba uluhlu olubanzi lweendawo zetsimbi. Enoba usebenza ngamashiti asicaba, iikhoyili, okanye imibhobho, lo matshini unokususa ngokufanelekileyo isikali kwiimilo ezahlukeneyo zentsimbi nobukhulu. Oku kuguquguquka kuyenza ibe lolona khetho lufanelekileyo kuluhlu olubanzi lwezicelo zamashishini.

Indlela yokuGcina ngokuLungileyo kunye nokuKhathalela uMshini oBuyiswayo wokuGobela uBuyiselo

Ngaphezu kokugcinwa rhoqo, kubalulekile ukulandela izikhokelo zomenzi wokusebenzisa umatshini. Oku kubandakanya ukulandela iinkqubo ezifanelekileyo zokhuseleko, ezifana nokunxiba izixhobo zokukhusela kunye nokuqinisekisa ukuba umatshini usekelwe ngokufanelekileyo. Kwakhona kubalulekile ukuphepha ukulayisha kakhulu umatshini, njengoko oku kunokubangela umonakalo kumalungu awo.

Ukugcinwa ngokufanelekileyo komatshini nako kubalulekile ukuqinisekisa ukuba uphila ixesha elide. Umatshini kufuneka ugcinwe kwindawo ecocekileyo, eyomileyo kude nokufuma kunye namaqondo obushushu agqithisileyo. Kwakhona kubalulekile ukugubungela umatshini xa ungasetyenziswanga ukukhusela eluthulini kunye nenkunkuma.

Ekuqukunjelweni, ukugcinwa okufanelekileyo kunye nokunyamekela umatshini wokuthoba ukugoba okubuyisela umva kubalulekile ukuqinisekisa ixesha elide kunye nokusebenza kakuhle. Ngokulandela iingcebiso ezichazwe kweli nqaku, unokunceda ukugcina umatshini wakho ukwimeko ephezulu kwaye uqinisekise ukuba uyaqhubeka nokusebenza kakuhle kwiminyaka ezayo. Khumbula ukucoca rhoqo kunye nokuhlola umatshini, ukuthambisa iindawo ezihambayo, ukuhlola izinto zombane, ukulandela iinkqubo zokhuseleko, kunye nokugcina umatshini ngokufanelekileyo. Ngokuthatha la manyathelo, unokunceda ukwandisa ubomi bomatshini wakho wokugoba obuyiselwe umva kwaye uqinisekise ukuba uyaqhubeka nokuhlangabezana neemfuno zakho zemveliso.

A reversed bending descaling machine is a crucial piece of equipment in many industrial settings, particularly in the metalworking industry. This machine is used to remove scale and other impurities from metal surfaces, ensuring that the finished product meets quality standards. Proper maintenance and care of a reversed bending descaling machine are essential to ensure its longevity and efficiency. In this article, we will discuss some key tips on how to properly maintain and care for a reversed bending descaling machine.

First and foremost, regular cleaning of the machine is essential to prevent the buildup of scale and other debris. This can be done by using a brush or vacuum to remove any loose particles from the machine’s surface. It is also important to regularly check and clean the machine’s filters to ensure that they are not clogged with debris, which can affect the machine’s performance.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, such as belts, chains, and bearings. Any damaged parts should be replaced immediately to prevent further damage to the machine.

Another important aspect of maintaining a reversed bending descaling machine is to regularly lubricate moving parts. This helps to reduce friction and wear on the machine, ensuring that it operates smoothly and efficiently. It is important to use the correct type of lubricant for each part of the machine, as using the wrong type can cause damage.

Regularly inspecting the machine’s electrical components is also crucial to ensure its safe operation. This includes checking for loose or damaged wires, as well as ensuring that all electrical connections are secure. Any damaged electrical components should be replaced by a qualified technician to prevent the risk of electrical hazards.

In addition to regular maintenance, it is important to follow the manufacturer’s guidelines for operating the machine. This includes following proper safety procedures, such as wearing protective gear and ensuring that the machine is properly grounded. It is also important to avoid overloading the machine, as this can cause damage to its components.

Proper storage of the machine is also important to ensure its longevity. The machine should be stored in a clean, dry environment away from moisture and extreme temperatures. It is also important to cover the machine when not in use to protect it from dust and debris.

In conclusion, proper maintenance and care of a reversed bending descaling machine are essential to ensure its longevity and efficiency. By following the tips outlined in this article, you can help to keep your machine in top condition and ensure that it continues to operate smoothly for years to come. Remember to regularly clean and inspect the machine, lubricate moving parts, inspect electrical components, follow safety procedures, and store the machine properly. By taking these steps, you can help to extend the life of your reversed bending descaling machine and ensure that it continues to meet your production needs.