Table of Contents

Maintenance Tips for Pulley Type Wire Drawing Machines

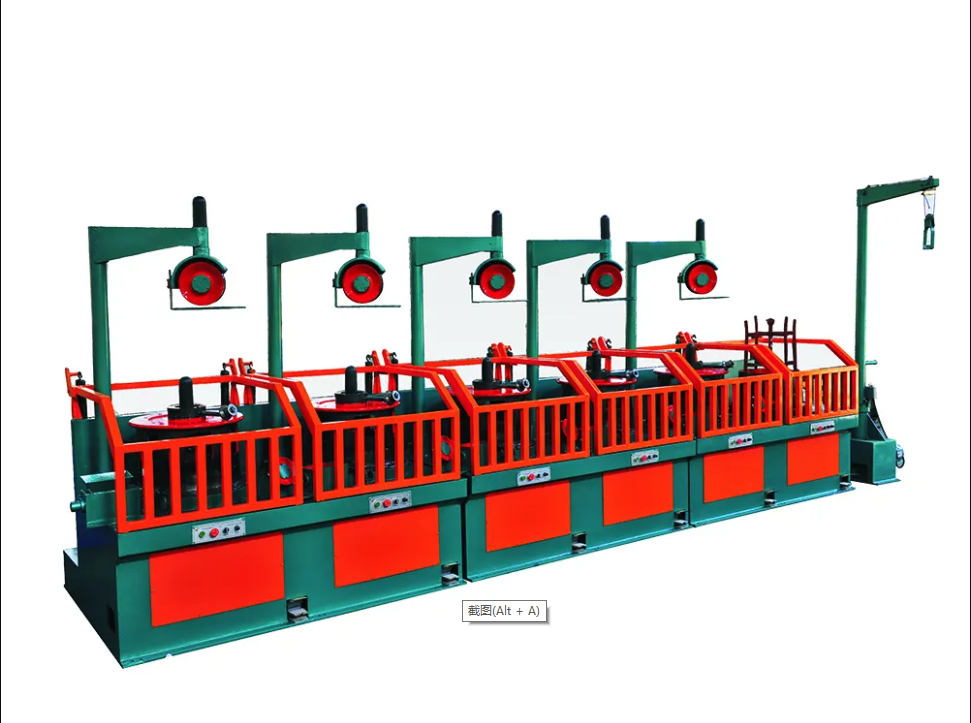

Pulley type wire drawing machines are essential equipment in the wire manufacturing industry. These machines are used to reduce the diameter of wire by pulling it through a series of dies. The pulley type wire drawing machine consists of a series of pulleys that guide the wire through the drawing process. Proper maintenance of these machines is crucial to ensure their optimal performance and longevity.

One of the most important maintenance tips for pulley type wire drawing machines is to regularly inspect and clean the pulleys. Over time, dust, dirt, and debris can accumulate on the pulleys, causing them to become less efficient. This can lead to increased friction and wear on the wire, resulting in poor quality output. Regularly cleaning the pulleys with a soft brush or cloth can help prevent this buildup and ensure smooth operation.

In addition to cleaning the pulleys, it is also important to regularly lubricate them to reduce friction and wear. Lubricating the pulleys with a high-quality lubricant can help prolong their lifespan and improve the overall efficiency of the machine. It is recommended to follow the manufacturer’s guidelines for the type and frequency of lubrication to ensure optimal performance.

Another important maintenance tip for Dry Type Wire Drawing Machine is to regularly inspect the dies for wear and damage. The dies are critical components of the machine that shape the wire as it is drawn through them. Over time, the dies can become worn or damaged, leading to poor quality output and potential machine breakdowns. Regularly inspecting the dies for signs of wear and replacing them as needed can help prevent these issues and ensure consistent performance.

In addition to inspecting and cleaning the pulleys and dies, it is also important to regularly check the tension of the wire during the drawing process. Proper tension is crucial for achieving the desired reduction in wire diameter and preventing breakages. Adjusting the tension as needed can help ensure smooth operation and high-quality output.

Regularly inspecting and replacing worn or damaged parts is another important maintenance tip for pulley type wire drawing machines. Over time, parts such as bearings, belts, and gears can become worn and need to be replaced to maintain optimal performance. Keeping a stock of spare parts on hand and regularly inspecting the machine for signs of wear can help prevent unexpected breakdowns and downtime.

Overall, proper maintenance of pulley type wire drawing machines is essential to ensure their optimal performance and longevity. Regularly cleaning and lubricating the pulleys, inspecting and replacing worn dies, checking wire tension, and inspecting and replacing worn parts are all important maintenance tips to follow. By following these tips, wire manufacturers can ensure that their pulley type wire drawing machines operate efficiently and produce high-quality wire products.

Advantages of Using Pulley Type Wire Drawing Machines

Pulley type wire drawing machines are a popular choice for manufacturers looking to efficiently produce high-quality wire products. These machines utilize a system of pulleys to draw wire through a series of dies, reducing its diameter and improving its surface finish. There are several advantages to using OTO Type Wire Drawing Machine, making them a valuable investment for businesses in various industries.

One of the primary advantages of pulley type wire drawing machines is their ability to produce wire with consistent diameter and surface finish. The pulley system allows for precise control over the drawing process, ensuring that the wire is drawn evenly and smoothly through each die. This results in wire that meets tight tolerances and is free from defects, making it ideal for use in applications where quality is paramount.

Another advantage of pulley type wire drawing machines is their versatility. These machines can be used to draw wire from a variety of materials, including steel, copper, and aluminum. They can also be used to produce wire in a wide range of diameters, making them suitable for a diverse range of applications. Whether you need fine wire for electronics or heavy-duty wire for construction, a pulley type wire drawing machine can meet your needs.

In addition to their precision and versatility, pulley type wire drawing machines are also known for their efficiency. These machines are designed to operate at high speeds, allowing for rapid production of wire in large quantities. This can help manufacturers meet tight deadlines and keep up with demand, ultimately improving their bottom line.

Furthermore, pulley type wire drawing machines are relatively easy to operate and maintain. With proper training, operators can quickly learn how to set up and run these machines, minimizing downtime and maximizing productivity. Additionally, routine maintenance tasks are straightforward and can be performed in-house, reducing the need for costly repairs and service calls.

Overall, pulley type wire drawing machines offer a range of advantages that make them a valuable asset for manufacturers. From their ability to produce high-quality wire with consistent diameter and surface finish to their versatility, efficiency, and ease of operation, these machines are well-suited for a variety of applications. Whether you are producing wire for electronics, construction, or any other industry, a pulley type wire drawing machine can help you meet your production goals and deliver top-quality products to your customers.

In conclusion, pulley type wire drawing machines are a reliable and efficient solution for manufacturers looking to produce high-quality wire products. With their precision, versatility, efficiency, and ease of operation, these machines offer a range of advantages that can help businesses improve their production processes and meet customer demands. If you are in the market for a wire drawing machine, consider investing in a pulley type model to take advantage of these benefits and enhance your manufacturing capabilities.