Table of Contents

IiNzuzo zokuSebenzisa umatshini wokuzoba woNxibelelwano lwePulley

Iingcebiso zoLondolozo lwePulley Type Wire Drawing Machine

Ukuthelekiswa kwePulley Type Wire Drawing Machine kunye nezinye iintlobo

Umzobo wocingo yinkqubo esetyenziswa kwishishini lemveliso ukunciphisa ububanzi bocingo ngokutsalwa kuluhlu lweedies. Le nkqubo ibalulekile ekuveliseni iingcingo zobukhulu obahlukeneyo kunye neemilo ezisetyenziswa kuluhlu olubanzi lwezicelo, ukusuka kwiingcingo zombane ukuya kucingo. Kukho iintlobo ezininzi zoomatshini bokuzoba ngocingo ezikhoyo, nganye ineempawu zayo ezizodwa kunye neenzuzo. Kule nqaku, siza kugxininisa kumatshini wokudweba ucingo lwe-pulley kwaye siwuqhathanise nezinye iintlobo zomatshini wokudweba ucingo.

Umatshini wokudweba ucingo lwe-pulley ngowona matshini usetyenziswa ngokuqhelekileyo kwishishini. Iqukethe uluhlu lweepuli ezisetyenziselwa ukutsala ucingo ngoluhlu lokufa, ukunciphisa ububanzi bayo kwinkqubo. Olu hlobo lomatshini luyaziwa ngokuba lula kunye nokulula ukusetyenziswa, okwenza kube yinto ethandwayo yokuzikhethela kubakhiqizi abaninzi.

Enye yeenzuzo eziphambili zomatshini wokudweba ucingo lwe-pulley kukuguquguquka kwayo. Lo matshini unokusetyenziselwa ukuzoba iingcingo zezinto ezahlukeneyo, kubandakanya intsimbi, ubhedu, kunye nealuminium. Ingasetyenziselwa ukuvelisa iingcingo zobubanzi obuhlukeneyo, okwenza ukuba zilungele uluhlu olubanzi lwezicelo. Ukongezelela, umatshini wokudweba ucingo lohlobo lwe-pulley kulula ukuseta nokusebenza, okwenza kube yinto ebiza imali eninzi kubenzi abaninzi.

Xa kuthelekiswa nezinye iindidi zoomatshini bokuzoba ngocingo, njengohlobo lwegubu kunye nohlobo lomgca othe ngqo. , umatshini wohlobo lwe-pulley unikezela ngeenzuzo ezininzi. Ngokomzekelo, umatshini wohlobo lwe-pulley waziwa ngokusebenza okuphezulu kunye nemveliso. Iipuli ezisetyenziswe kulo matshini zenzelwe ukunciphisa ukungqubuzana kunye nokuqinisekisa ukusebenza kakuhle, okubangelwa ukukhawuleza kwesantya sokudweba kunye nokukhutshwa okuphezulu.

Enye inzuzo yomshini wokudweba ucingo lwe-pulley kukukwazi ukuvelisa iingcingo ngezinga eliphezulu lokuchaneka. Iipuli ezisetyenziswe kulo matshini zinokuhlengahlengiswa ukulawula ukunyanzeliswa kunye nesantya socingo, ukuvumela ukulawula okuchanekileyo kwinkqubo yokudweba. Oku kubangela iingcingo ezinobubanzi obufanayo kwaye zibe nomphezulu ogudileyo, zizenze zilungele uluhlu olubanzi lwezicelo.

Ngaphandle kweenzuzo ezininzi, umatshini wokudweba ucingo wohlobo lwepulley unemida ethile. Ngokomzekelo, olu hlobo lomatshini alufanelekanga ukutsala iingcingo ezinobubanzi obuncinci kakhulu, njengoko iipuli zingenako ukubonelela ngoxinzelelo olwaneleyo lokutsala ucingo ngokufa. Ukongeza, umatshini wohlobo lwe-pulley unokufuna ukugcinwa okungaphezulu kunezinye iintlobo zoomatshini bokuzoba, njengoko iipuli zinokuguga ngokuhamba kwexesha kwaye zifuna ukutshintshwa. abavelisi abafuna ukuvelisa iingcingo zobukhulu obahlukeneyo kunye nemathiriyeli. Nangona kunokuba nemingcele ethile, njengobunzima bokudweba iingcingo ezincinci kakhulu kunye nesidingo sokugcinwa rhoqo, umatshini wohlobo lwe-pulley unikezela ngeenzuzo ezininzi, kubandakanywa ukusebenza kakuhle, ukuvelisa, kunye nokuchaneka. Ngokubanzi, umatshini wokudweba ucingo lwe-pulley lukhetho oluthembekileyo nolunexabiso eliphantsi kubavelisi abaninzi kwishishini.

A pulley type wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. It is used to pull wire through a series of dies to reduce its diameter and improve its quality. To ensure the smooth operation of the machine and prevent breakdowns, regular maintenance is essential. In this article, we will discuss some maintenance tips for pulley type wire drawing machines.

One of the most important maintenance tasks for a pulley type wire drawing machine is lubrication. Proper lubrication of the machine’s moving parts, such as the pulleys, bearings, and gears, is essential to reduce friction and wear. It is recommended to use high-quality lubricants that are suitable for the specific components of the machine. Regularly check the lubrication levels and top up as needed to ensure smooth operation.

In addition to lubrication, regular inspection of the machine is also crucial. Check for any signs of wear or damage on the pulleys, dies, and other components. Replace any worn or damaged parts immediately to prevent further damage to the machine. Inspect the belts and chains for any signs of wear and tension them as needed. Regular inspection can help identify potential issues before they escalate into major problems.

Another important maintenance task for a pulley type wire drawing machine is cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. Regularly clean the machine using a soft brush or cloth to remove any buildup. Pay special attention to the pulleys and dies, as any debris on these components can affect the quality of the wire being produced.

It is also important to check the alignment of the pulleys on the machine. Misaligned pulleys can cause uneven tension on the wire, leading to quality issues. Use a straight edge or laser alignment tool to check the alignment of the pulleys and adjust them as needed. Proper alignment of the pulleys is essential for the smooth operation of the machine and the production of high-quality wire.

Regularly check the tension of the wire on the machine. Improper tension can cause the wire to break or slip, leading to production delays and quality issues. Adjust the tension of the wire as needed to ensure smooth operation. It is also important to check the speed of the machine and adjust it according to the type of wire being drawn. Proper speed control is essential for producing wire of the desired diameter and quality.

In conclusion, proper maintenance of a pulley type wire drawing machine is essential for ensuring its smooth operation and longevity. Regular lubrication, inspection, cleaning, alignment, and tensioning are key maintenance tasks that should be performed regularly. By following these maintenance tips, you can prevent breakdowns, improve the quality of the wire produced, and extend the life of your machine. Remember, a well-maintained machine is a productive machine.

Comparison of Pulley Type Wire Drawing Machine with Other Types

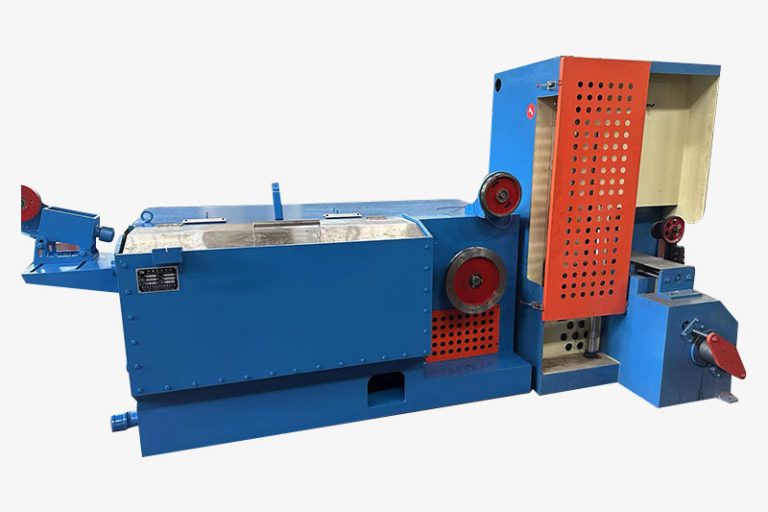

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. There are several types of wire drawing machines available, each with its own unique features and advantages. In this article, we will focus on the pulley type wire drawing machine and compare it with other types of wire drawing machines.

The pulley type wire drawing machine is one of the most commonly used machines in the industry. It consists of a series of pulleys that are used to pull the wire through a series of dies, reducing its diameter in the process. This type of machine is known for its simplicity and ease of use, making it a popular choice for many manufacturers.

One of the main advantages of the pulley type wire drawing machine is its versatility. This machine can be used to draw wires of various materials, including steel, copper, and aluminum. It can also be used to produce wires of different diameters, making it suitable for a wide range of applications. Additionally, the pulley type wire drawing machine is relatively easy to set up and operate, making it a cost-effective option for many manufacturers.

In comparison to other types of wire drawing machines, such as the drum type and the straight line type, the pulley type machine offers several advantages. For example, the pulley type machine is known for its high efficiency and productivity. The pulleys used in this machine are designed to minimize friction and ensure smooth operation, resulting in faster drawing speeds and higher output.

Another advantage of the pulley type wire drawing machine is its ability to produce wires with a high degree of precision. The pulleys used in this machine can be adjusted to control the tension and speed of the wire, allowing for precise control over the drawing process. This results in wires that are uniform in diameter and have a smooth surface finish, making them suitable for a wide range of applications.

Despite its many advantages, the pulley type wire drawing machine does have some limitations. For example, this type of machine may not be suitable for drawing wires with very small diameters, as the pulleys may not be able to provide enough tension to pull the wire through the dies. Additionally, the pulley type machine may require more maintenance than other types of wire drawing machines, as the pulleys can wear out over time and need to be replaced.

In conclusion, the pulley type wire drawing machine is a versatile and efficient option for manufacturers looking to produce wires of various sizes and materials. While it may have some limitations, such as difficulty in drawing very small wires and the need for regular maintenance, the pulley type machine offers many advantages, including high efficiency, productivity, and precision. Overall, the pulley type wire drawing machine is a reliable and cost-effective choice for many manufacturers in the industry.