Table of Contents

Iingcebiso zoLondolozo lwezikhonkwane ziFa koomatshini bokwenza izikhonkwane

Izikhonkwane ziyafa yinxalenye ebalulekileyo yoomatshini bokwenza izikhonkwane, abanoxanduva lokubumba kunye nokusika izikhonkwane zibe kubungakanani obufunwayo kunye nokumila kwazo. Ukugcinwa ngokufanelekileyo kwezikhonkwane ezifayo kubalulekile ukuqinisekisa ukusebenza ngokufanelekileyo komatshini wokwenza izikhonkwane kunye nokuveliswa kwezikhonkwane ezikumgangatho ophezulu. Kweli nqaku, siza kuxoxa ngezinye iingcebiso zokugcina iinzipho ziyafa koomatshini bokwenza iinzipho.

Indlela yokukhetha iNzipho eLungileyo Die kumatshini wakho wokwenza izikhonkwane

Enye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha i-Nail Die yimpahla yokufa. Izikhonkwane ezifayo zenziwe ngentsimbi ekumgangatho ophezulu okanye i-carbide, kwaye i-carbide yeyona nto ihlala ihleli kwaye ithatha ixesha elide. Ngelixa isikhonkwane sokufa sifikeleleka ngakumbi, sinokuguga ngokukhawuleza kwaye sifune ukutshintshwa rhoqo. Kwelinye icala, i-carbide nail dies ibiza kakhulu ngaphambili kodwa inika ukuqina okuphezulu kunye nobomi obude, ibenza babe lukhetho olungabizi kakhulu ekuhambeni kwexesha. Qwalasela uhlahlo lwabiwo-mali lwakho kunye nomthamo wemveliso xa usenza isigqibo phakathi kwentsimbi kunye ne-carbide nail dies.

Ukuhambelana nomatshini wakho wokwenza izikhonkwane kukwaluqwalaselo olubalulekileyo xa ukhetha ukufa kwesikhonkwane. Ayizizo zonke iinzipho ezifayo ziyahambelana nabo bonke oomatshini bokwenza izikhonkwane, ngoko ke kubalulekile ukuqinisekisa ukuba isikhonkwane esifayo esisikhethayo siyilelwe ukusebenza ngemodeli yakho yomatshini othile. Jonga iinkcukacha zokufa kwesikhonkwane kunye nomatshini wakho wokwenza izikhonkwane ukuze uqinisekise ukuhambelana ngaphambi kokuthenga. Ukusebenzisa i-nail die engahambelaniyo kunokukhokelela kumgangatho ophantsi wezikhonkwane, ukungasebenzi komatshini, kunye nokulungiswa okuxabisa kakhulu.

Ngaphezu kokuqwalasela uhlobo lwezikhonkwane, izinto eziphathekayo, kunye nokuhambelana, kubalulekile ukukhetha umenzi ohloniphekileyo xa uthengela i-nail die for your. umatshini wokwenza iinzipho. Khangela abavelisi kunye nerekhodi eqinisekisiweyo yokuvelisa i-nail ephezulu yokufa ethembekileyo kwaye ihlala njalo. Ukufunda uphononongo lwabathengi kunye nobungqina bunokukunceda ukuba ulinganise umgangatho weemveliso zomenzi kunye nenkonzo yabathengi. Ukutshala imali kwi-nail kufa kumenzi ohloniphekileyo kuya kuqinisekisa ukuba ufumana imveliso ephezulu ehlangabezana neemfuno zakho zemveliso.

Ekuqukumbeleni, ukukhetha isikhonkwane esifanelekileyo sokufa kumatshini wakho wokwenza izikhonkwane kubalulekile ekuveliseni izipikili eziphezulu ngokufanelekileyo. Qwalasela uhlobo lwezikhonkwane ofuna ukuvelisa, izinto zokufa kwesikhonkwane, ukuhambelana nomatshini wakho, kunye nodumo lomenzi xa ukhetha ukufa kwesikhonkwane. Ngokuphonononga ngononophelo ezi zinto, unokuqinisekisa ukuba ukhetha ukufa kwesikhonkwane esihlangabezana neemfuno zakho zemveliso kwaye sinikeze iziphumo ezingaguqukiyo nezithembekileyo.

How to Choose the Right Nail Die for Your Nail Making Machine

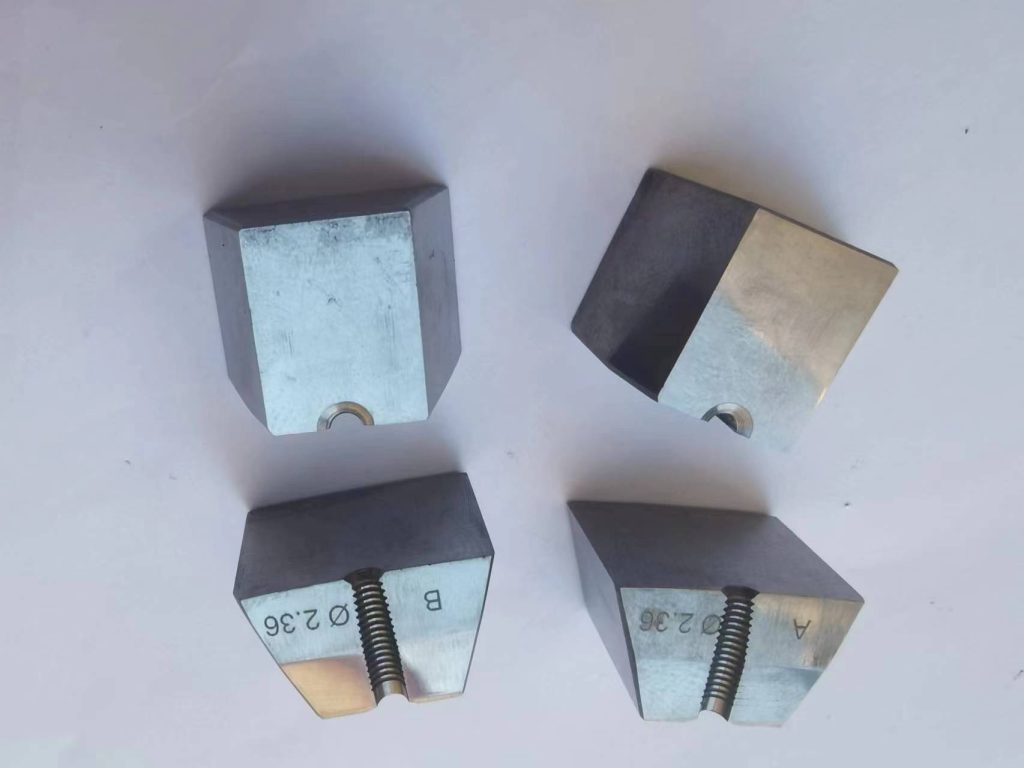

When it comes to nail making machines, one of the most crucial components is the nail die. The nail die is responsible for shaping the wire into the desired nail shape, and choosing the right nail die for your nail making machine is essential for producing high-quality nails efficiently. There are several factors to consider when selecting a Carrie Block For Enkotec Nail Making Machine, including the type of nails you want to produce, the material of the nail die, and the compatibility with your nail making machine.

First and foremost, you need to consider the type of nails you want to produce. Different nail dies are designed for specific nail shapes and sizes, so it’s important to choose a nail die that is suitable for the nails you want to manufacture. Whether you are producing common nails, roofing nails, or finishing nails, there is a nail die available to meet your needs. Make sure to carefully evaluate the specifications of each nail die to ensure it is compatible with the nails you want to produce.

Another important factor to consider when choosing a nail die is the material of the die. Nail dies are typically made from high-quality steel or carbide, with carbide being the more durable and long-lasting option. While steel nail dies are more affordable, they may wear out more quickly and require more frequent replacement. On the other hand, carbide nail dies are more expensive upfront but offer superior durability and longevity, making them a cost-effective choice in the long run. Consider your budget and production volume when deciding between steel and carbide nail dies.

Compatibility with your nail making machine is also a crucial consideration when selecting a nail die. Not all nail dies are compatible with all nail making machines, so it’s important to ensure that the nail die you choose is designed to work with your specific machine model. Check the specifications of both the nail die and your nail making machine to confirm compatibility before making a purchase. Using an incompatible nail die can result in poor nail quality, machine malfunctions, and costly repairs.

In addition to considering the type of nails, material, and compatibility, it’s also important to choose a reputable manufacturer when purchasing a nail die for your nail making machine. Look for manufacturers with a proven track record of producing high-quality nail dies that are reliable and durable. Reading customer reviews and testimonials can help you gauge the quality of a manufacturer’s products and customer service. Investing in a nail die from a reputable manufacturer will ensure that you receive a high-quality product that meets your production needs.

In conclusion, choosing the right nail die for your nail making machine is essential for producing high-quality nails efficiently. Consider the type of nails you want to produce, the material of the nail die, compatibility with your machine, and the reputation of the manufacturer when selecting a nail die. By carefully evaluating these factors, you can ensure that you choose a nail die that meets your production requirements and delivers consistent, reliable results.