Izinto eziLungileyo zokuSebenzisa isiKali seNcingo esingoomatshini esineyunithi yokubrasha ngocingo

Kulonke, izibonelelo zokusebenzisa isixhobo sokususa i-wire mechanical kunye neyunithi yokuxubha ucingo zicacile. Ukusuka ekuphuculeni umgangatho wemveliso kunye nenkangeleko ukuya ekwandiseni ukusebenza kakuhle kwemveliso kunye nokwandisa ixesha lokuphila kweemveliso zocingo, lo matshini ovelisa izinto ezintsha ubonelela ngoluhlu lweenzuzo kubavelisi kumashishini ahlukeneyo. Ngokwenza utyalo-mali kwisixhobo sokucoca ucingo ngomatshini ngeyunithi yokubrasha ucingo, iinkampani zinokuphucula ukusebenza kwazo kwaye zifezekise impumelelo enkulu kwindawo yentengiso ekhuphisanayo.

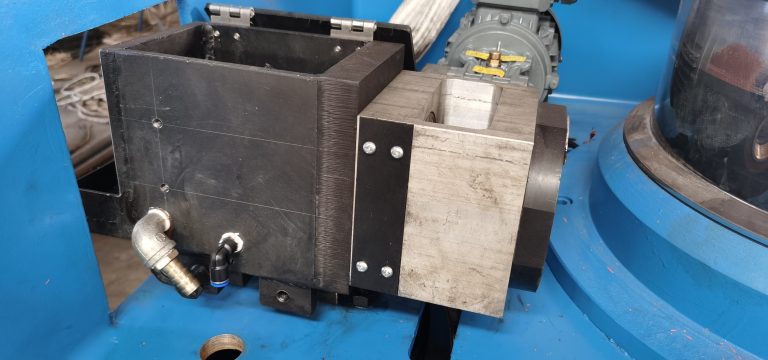

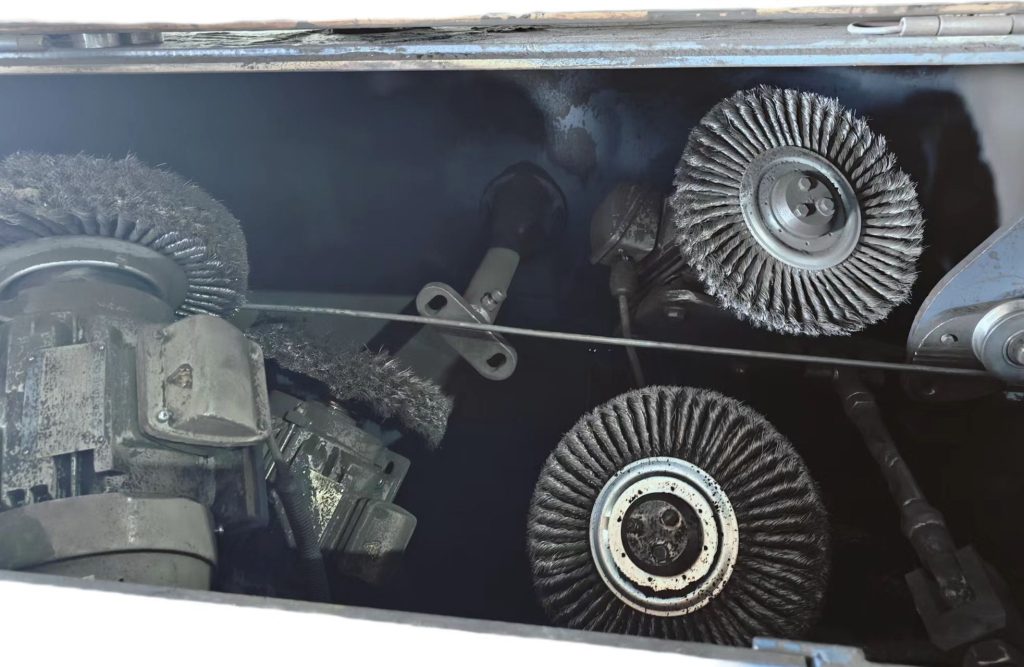

One of the primary merits of using a Mechanical Wire Descaler with a wire brushing unit is the ability to remove rust, scale, and other surface contaminants from wire products quickly and effectively. This process is essential for ensuring that the wire is clean and free from any impurities that could compromise its strength and durability. By using a mechanical wire descaler with a wire brushing unit, manufacturers can achieve a high level of cleanliness and consistency in their wire products, leading to improved quality and performance.

In addition to removing surface contaminants, a mechanical wire descaler with a wire brushing unit can also help to improve the surface finish of wire products. The wire brushing unit is designed to smooth out any rough spots or imperfections on the surface of the wire, resulting in a more uniform and aesthetically pleasing finish. This can be particularly important for industries that require wire products to have a smooth and polished appearance, such as the automotive or jewelry industries.

Another key benefit of using a mechanical wire descaler with a wire brushing unit is the ability to increase production efficiency. By automating the process of descaling and brushing wire products, manufacturers can significantly reduce the time and labor required to prepare the wire for further processing. This can lead to faster turnaround times, increased output, and lower production costs. Additionally, the consistent and precise nature of the mechanical wire descaler ensures that each wire product is processed to the same high standard, reducing the risk of errors or defects.

Furthermore, a mechanical Steel Brush Descaler for Wire Drawing Process can help to extend the lifespan of wire products. By removing surface contaminants and smoothing out imperfections, the wire brushing unit can help to prevent corrosion and other forms of degradation that can occur over time. This can result in wire products that are more durable and long-lasting, reducing the need for frequent replacements and repairs. Ultimately, this can lead to cost savings for manufacturers and a higher level of satisfaction for customers.

Overall, the benefits of using a mechanical wire descaler with a wire brushing unit are clear. From improving product quality and appearance to increasing production efficiency and extending the lifespan of wire products, this innovative machine offers a range of advantages for manufacturers in various industries. By investing in a mechanical wire descaler with a wire brushing unit, companies can enhance their operations and achieve greater success in the competitive marketplace.