Table of Contents

IiNzuzo zokuSebenzisa i-LT-350 yoMshini wokuzoba ngocingo olumanzi

Iingcebiso zoLondolozo lwe-LT-350 yoMshini wokuzoba ngocingo olumanzi

Umatshini wokuzoba ngocingo omanzi we-LT-350 sisixhobo esibalulekileyo kushishino lokwenziwa kweengcingo. Isetyenziselwa ukuzoba ucingo ngoluhlu lokufa ukunciphisa ububanzi bayo kunye nokuphucula umgangatho wayo. Ukugcinwa ngokufanelekileyo kwe-LT-350 ye-wet wire drawing machine ibalulekile ukuze kuqinisekiswe ukusebenza kwayo ngokugqibeleleyo kunye nokuphila ixesha elide.

Omnye wemisebenzi ebalulekileyo yokugcina i-LT-350 Wet Wire Drawing Machine kukucoca rhoqo. Uthuli, ukungcola, kunye nobutyobo bunokuqokelelana kumatshini ekuhambeni kwexesha, okukhokelela ekunciphiseni ukusebenza kakuhle kunye nomonakalo onokwenzeka. Kunconywa ukuba uhlambulule umatshini imihla ngemihla okanye njengoko kufuneka, usebenzisa ibrashi ethambileyo okanye ilaphu ukususa nayiphi na i-buildup.

Ngaphezu kokucoca, i-lubrication enye inkalo ebalulekileyo yokugcina i-LT-350 Wet Wire Drawing Machine. Ukuthambisa okufanelekileyo kwamacandelo ahambayo kunceda ukunciphisa ukungqubuzana kunye nokugqoka, ukwandisa ubomi bomatshini. Kubalulekile ukusebenzisa uhlobo oluchanekileyo kunye nesixa sesithambiso esichazwe ngumvelisi ukuqinisekisa ukusebenza ngokupheleleyo.

Ukuhlola umatshini rhoqo nako kubalulekile ukuchonga nayiphi na imiba enokubakho ngaphambi kokuba inyuke. Khangela iindawo ezikhululekileyo okanye ezonakeleyo, ingxolo engaqhelekanga, okanye iimpawu zokuguga. Ukujongana nale miba ngokukhawuleza kunokuthintela ukulungiswa okuxabisa imali eninzi kunye nexesha lokuphumla.

Enye ingcebiso yolondolozo ebalulekileyo yoMshini wokuzoba i-LT-350 Wet Wire Drawing Machine kukubeka esweni ukuxinana kocingo ngexesha lokusebenza. Uxinzelelo olufanelekileyo lubalulekile ekufezekiseni idiameter yocingo olufunekayo kunye nomgangatho. Lungisa ukuxinana njengoko kufuneka ukuqinisekisa ukusebenza kakuhle kunye neziphumo ezingaguqukiyo.

Kukwabalulekile ukugcina inkqubo yokupholisa yoMshini wokuzoba i-LT-350 Wet Wire Drawing ukwimeko elungileyo yokusebenza. Ukupholisa kunceda ukunciphisa ubushushu kunye nokukhuhla ngexesha lokuzoba, ukuphucula umgangatho wocingo. Jonga rhoqo inqanaba lokupholisa kunye nomgangatho, kwaye ubeke endaweni yayo njengoko kufuneka ukugcina ukusebenza kakuhle.

Uqeqesho olufanelekileyo lwabaqhubi lubalulekile ekusebenzeni ngokufanelekileyo nangokukhuselekileyo koMshini wokuzoba i-LT-350 Wet Wire Drawing. Qinisekisa ukuba abaqhubi banolwazi ngokusebenza nokugcinwa komatshini, kwaye banike uqeqesho oluqhubekayo njengoko lufuneka. Oku kuya kunceda ukuthintela iingozi kunye nokuqinisekisa ixesha elide lomatshini.

Ekuqukumbeleni, ukugcinwa ngokufanelekileyo koMshini wokuzoba i-LT-350 Wet Wire Drawing kubalulekile ukuqinisekisa ukusebenza kwawo kakuhle kunye nokuphila ixesha elide. Ukucocwa rhoqo, ukuthambisa, ukuhlolwa, ukujongwa koxinzelelo, ukugcinwa kwenkqubo yokupholisa, kunye noqeqesho lwabaqhubi yimiba ephambili yokugcina umatshini. Ngokulandela ezi ngcebiso zogcino, unokwandisa ubomi bomatshini wakho wokuzoba we-LT-350 we-Wet Wire Drawing kwaye ufumane iziphumo ezingaguquguqukiyo, ezikumgangatho ophezulu wokwenziwa kweengcingo.

Maintenance Tips for LT-350 Wet Wire Drawing Machine

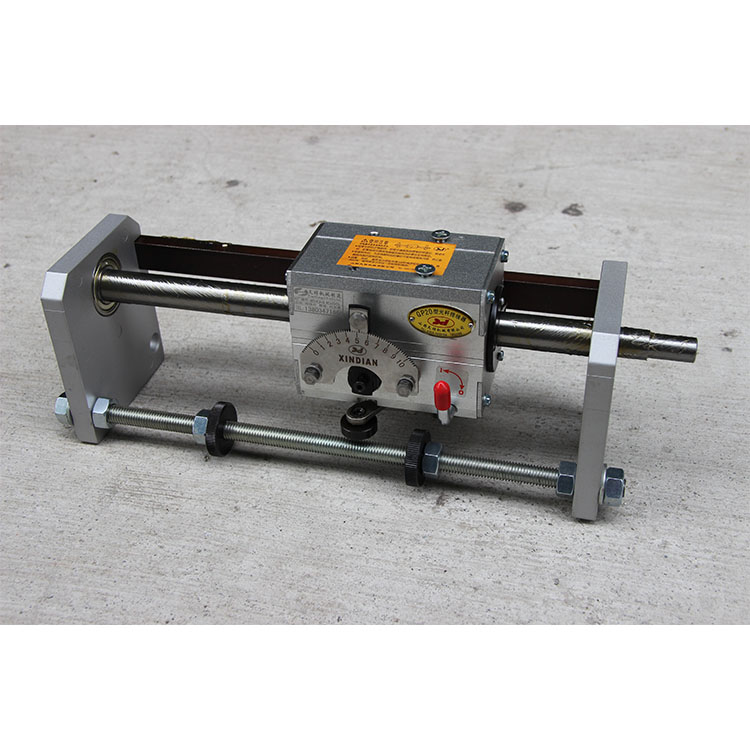

The LT-350 Wet Wire Drawing Machine is a crucial piece of equipment in the wire manufacturing industry. It is used to draw wire through a series of dies to reduce its diameter and improve its quality. Proper maintenance of the LT-350 Wet Wire Drawing Machine is essential to ensure its optimal performance and longevity.

One of the most important maintenance tasks for the LT-350 Wet Wire Drawing Machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine over time, leading to decreased efficiency and potential damage. It is recommended to clean the machine daily or as needed, using a soft brush or cloth to remove any buildup.

In addition to cleaning, lubrication is another key aspect of maintaining the LT-350 Wet Wire Drawing Machine. Proper lubrication of moving parts helps reduce friction and wear, extending the life of the machine. It is important to use the correct type and amount of lubricant specified by the manufacturer to ensure optimal performance.

Regular inspection of the machine is also essential to identify any potential issues before they escalate. Check for loose or damaged parts, unusual noises, or signs of wear and tear. Addressing these issues promptly can prevent costly repairs and downtime.

Another important maintenance tip for the LT-350 Wet Wire Drawing Machine is to monitor the tension of the wire during operation. Proper tension is crucial for achieving the desired wire diameter and quality. Adjust the tension as needed to ensure smooth operation and consistent results.

It is also important to keep the coolant system of the LT-350 Wet Wire Drawing Machine in good working condition. The coolant helps reduce heat and friction during the drawing process, improving the quality of the wire. Regularly check the coolant level and quality, and replace it as needed to maintain optimal performance.

Proper training of operators is essential for the efficient and safe operation of the LT-350 Wet Wire Drawing Machine. Make sure that operators are familiar with the machine’s operation and maintenance procedures, and provide ongoing training as needed. This will help prevent accidents and ensure the longevity of the machine.

In conclusion, proper maintenance of the LT-350 Wet Wire Drawing Machine is essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection, tension monitoring, coolant system maintenance, and operator training are key aspects of maintaining the machine. By following these maintenance tips, you can extend the life of your LT-350 Wet Wire Drawing Machine and achieve consistent, high-quality results in wire manufacturing.