Table of Contents

Izinto eziluncedo zokuSebenzisa i-Linear Traverse Mechanism kwi-Industrial Applications

Uyenyuswa Njani iNdlela yokuNxibelelana ngeMigca ukuze kuPhuculwe iNdlela yokuSebenza

Iindlela zokunqumla ngomgca ngamacandelo ayimfuneko kwizicelo ezahlukeneyo zemizi-mveliso, kubandakanywa oomatshini be-CNC, abashicileli be-3D, kunye nemigca yendibano ezenzekelayo. Ezi ndlela zinoxanduva lokuhambisa isixhobo okanye iworkpiece kwindlela ethe tye ngokuchaneka nokuchaneka. Ukuqinisekisa ukusebenza ngeyona ndlela iphezulu, kubalulekile ukunyusa umgangatho wendlela yokucanda ngokuqwalasela imiba efana nesantya, ukuchaneka, kunye nokuthembeka.

Enye yezinto eziphambili ekufuneka ziqwalaselwe xa kunyuswa umgca wokunqumla indlela sisantya. Isantya apho umatshini unokuhambisa isixhobo okanye i-workpiece ecaleni kwendlela yomgca ichaphazela ngokuthe ngqo ukusebenza kakuhle kwenkqubo. Ukuphucula isantya, kubalulekile ukunciphisa ukukhuhla kunye nokuchasana ngaphakathi kwesixhobo. Oku kunokufumaneka ngokusebenzisa iibheringi ezikumgangatho ophezulu, izithambiso, kunye nezinto ezinciphisa ukukhuhlana nokuguga. Ukongeza, ukulungelelanisa i-motor kunye nenkqubo yokuqhubela phambili kunokuncedisa ukwandisa isantya se-linear traverse mechanism.

Ukongeza kwisantya, ukuchaneka yenye into ebalulekileyo ekufuneka iqwalaselwe xa ulungiselela umgca wokunqumla umgca. Ukuchaneka kubalulekile kwizicelo apho unyamezelo olungqongqo lufuneka, njengokwenziwa kwezixhobo ze-elektroniki okanye izixhobo zonyango. Ukuphucula ukuchaneka, kubalulekile ukunciphisa umva kunye nokudlala ngaphakathi kwendlela. Oku kunokufezekiswa ngokusebenzisa amacandelo achanekileyo kunye nokuphumeza ukulinganisa okufanelekileyo kunye neenkqubo zokulungelelanisa. Ukongeza, ukubandakanya izivamvo zengxelo ezinjengeekhowudi okanye izikali zomgca zinganceda ukuqinisekisa ukuba umatshini uhamba ngokuchaneka okufunekayo.

Ukuthembeka kukwangumba obalulekileyo omawuqwalaselwe xa unyusela umgca wokucanda indlela. Indlela ethembekileyo ibalulekile ekuqinisekiseni ukusebenza okufanayo kunye nokunciphisa ixesha lokuphumla. Ukuphucula ukuthembeka, kubalulekile ukusebenzisa amacandelo aphezulu enzelwe ukuqina kunye nokuphila ixesha elide. Ukugcinwa rhoqo kunye nokuhlolwa komatshini kunganceda ukuchonga nokujongana nayo nayiphi na imiba enokubakho ngaphambi kokuba inyuke ibe yingxaki enkulu. Ukongeza, ukuphumeza amanyathelo okhuseleko afanelekileyo kunye neeprothokholi kunokunceda ukuthintela iingozi kunye nomonakalo kumatshini.

Ukwandisa ngakumbi umgca wokunqumla indlela, kubalulekile ukuqwalasela ukuyilwa kwenkqubo kunye nokudibanisa. Umtshini kufuneka udityaniswe ngokufanelekileyo namanye amacandelo afana neenjini, izilawuli, kunye nezinzwa zokuqinisekisa ukusebenza ngokungenamthungo. I-wiring efanelekileyo kunye nolawulo lwekhebula lunokunceda ukukhusela ukuphazamiseka kunye nokulahleka kweempawu, ezinokuchaphazela ukusebenza kwendlela. Ukongezelela, ukuphumeza inkqubo efanelekileyo kunye nokulawula i-algorithms kunokunceda ukwandisa iphrofayili eshukumayo kunye ne-trajectory yendlela yokusebenza ephuculweyo.

Ngokuqwalasela izinto ezifana nesantya, ukuchaneka, ukuthembeka, kunye nokudityaniswa kwenkqubo, kunokwenzeka ukwandisa ukusebenza kakuhle kunye nokusebenza kakuhle komatshini. Ngokulondolozwa okufanelekileyo, ulungelelwaniso, kunye nokuqwalaselwa koyilo, indlela enqamlezayo enqamlezayo inokubonelela ngentshukumo engaguqukiyo nechanekileyo ecaleni kwendlela ethe tye, inegalelo kwimpumelelo yonke yenkqubo.

How to Optimize Linear Traverse Mechanism for Improved Performance

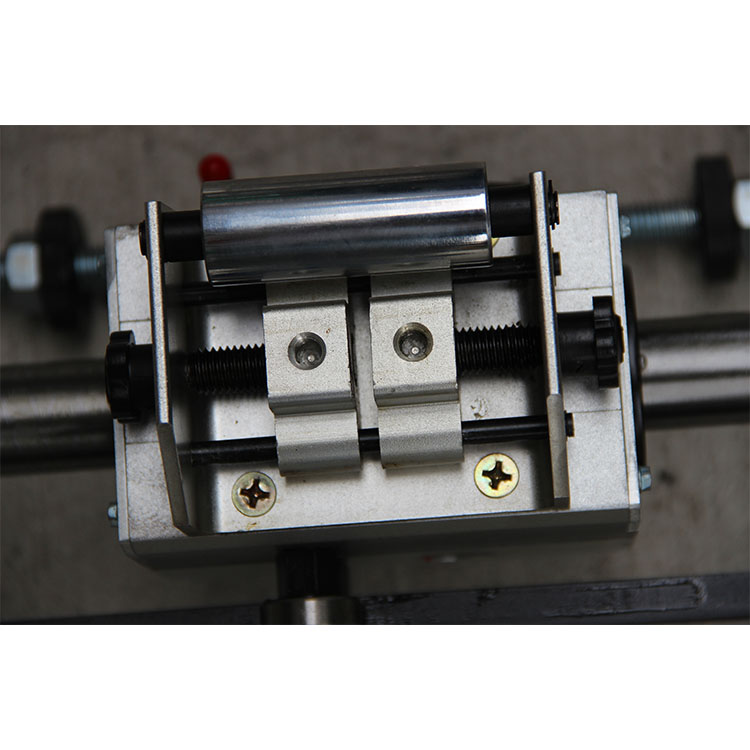

Linear traverse mechanisms are essential components in various industrial applications, including CNC machines, 3D printers, and automated assembly lines. These mechanisms are responsible for moving a tool or workpiece along a straight path with precision and accuracy. To ensure optimal performance, it is crucial to optimize the linear traverse mechanism by considering factors such as speed, accuracy, and reliability.

One of the key factors to consider when optimizing a linear traverse mechanism is speed. The speed at which the mechanism can move the tool or workpiece along the linear path directly impacts the overall efficiency of the system. To improve speed, it is essential to minimize friction and resistance within the mechanism. This can be achieved by using high-quality bearings, lubricants, and materials that reduce friction and wear. Additionally, optimizing the motor and drive system can help increase the speed of the linear traverse mechanism.

In addition to speed, accuracy is another critical factor to consider when optimizing a linear traverse mechanism. Precision is essential in applications where tight tolerances are required, such as in the manufacturing of electronic components or medical devices. To improve accuracy, it is important to minimize backlash and play within the mechanism. This can be achieved by using high-precision components and implementing proper calibration and alignment procedures. Additionally, incorporating feedback sensors such as encoders or linear scales can help ensure that the mechanism moves with the desired accuracy.

Reliability is also a crucial aspect to consider when optimizing a linear traverse mechanism. A reliable mechanism is essential for ensuring consistent performance and minimizing downtime. To improve reliability, it is important to use high-quality components that are designed for durability and longevity. Regular maintenance and inspection of the mechanism can help identify and address any potential issues before they escalate into major problems. Additionally, implementing proper safety measures and protocols can help prevent accidents and damage to the mechanism.

To further optimize a linear traverse mechanism, it is important to consider the overall system design and integration. The mechanism should be properly integrated with other components such as motors, controllers, and sensors to ensure seamless operation. Proper wiring and cable management can help prevent interference and signal loss, which can affect the performance of the mechanism. Additionally, implementing proper programming and control algorithms can help optimize the motion profile and trajectory of the mechanism for improved performance.

In conclusion, optimizing a linear traverse mechanism is essential for achieving optimal performance in various industrial applications. By considering factors such as speed, accuracy, reliability, and system integration, it is possible to enhance the efficiency and effectiveness of the mechanism. With proper maintenance, calibration, and design considerations, a linear traverse mechanism can provide consistent and precise motion along a straight path, contributing to the overall success of the system.