Ukubaluleka kweemela ezikwiMgangatho oPhezulu kumatshini wokwenza izikhonkwane we-Enkotec

Ekuqukunjelweni, ukubaluleka kweemela ezikumgangatho ophezulu kumatshini wokwenza izikhonkwane ze-Enkotec azikwazi ukugqithiswa. Ezi iimela ziyimfuneko ekuqinisekiseni ukusebenza kakuhle kunye nokusebenza kakuhle koomatshini, kunye nokuveliswa kwezikhonkwane eziphezulu. Ngokukhetha iimela ezenziwe ngezinto ezihlala ixesha elide, uyilo lobunjineli obuchanekileyo, kunye nemiphetho ebukhali yokusika, abavelisi banokuphucula ukusebenza kunye nokuphila ixesha elide koomatshini babo bokwenza izikhonkwane be-Enkotec. Ukugcinwa rhoqo kunye nokulolwa kweemela nako kubalulekile ekugcineni ukusebenza kakuhle kunye nokunciphisa iindleko zemveliso. Utyalo-mali kwiimela ezikumgangatho ophezulu zoomatshini bokwenza iinzipho be-Enkotec sisigqibo esilumkileyo esinokukhokelela ekuphuculweni kwemveliso, ukunciphisa ixesha lokuphumla, kunye nomgangatho ophezulu wemveliso yezikhonkwane.

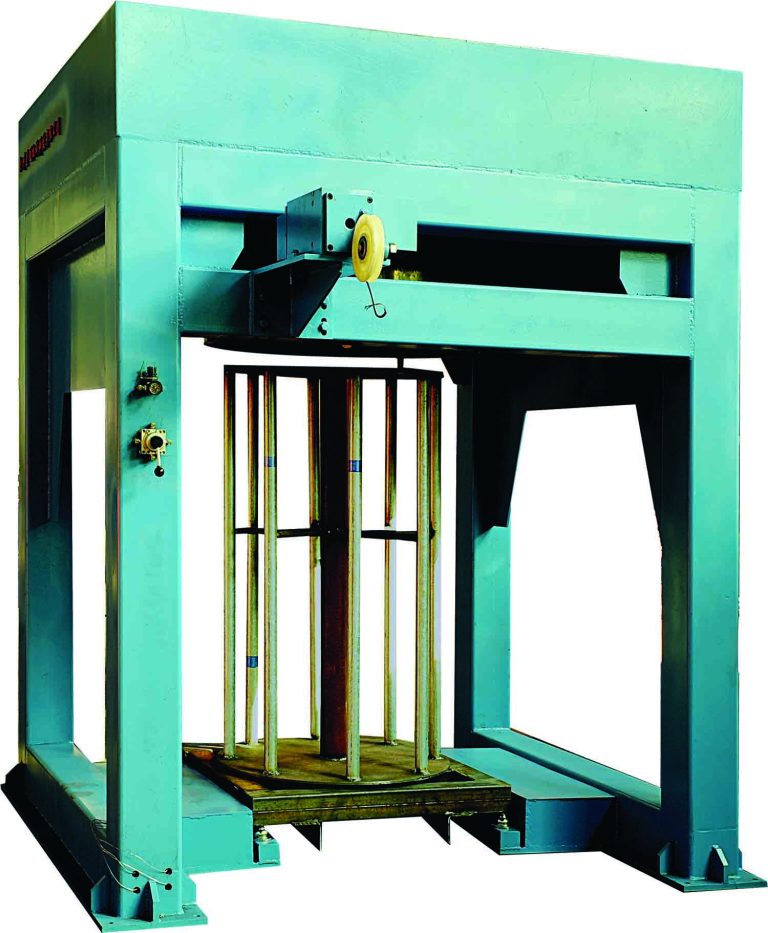

High-quality knives are essential for ensuring the smooth and precise cutting of wire into nails. The knives used in Enkotec Nail Making Machines must be durable, sharp, and able to withstand the high-speed cutting process. Inferior quality knives can result in uneven cuts, jagged edges, and frequent blade replacements, leading to production delays and increased costs.

One of the key factors to consider when selecting Carrie Block For Enkotec Nail Making Machine is the material used in their construction. Knives made from high-quality materials such as tool steel or carbide are more durable and resistant to wear and tear. These materials are able to maintain their sharpness over a longer period of time, resulting in consistent and precise cuts.

In addition to the material used, the design and manufacturing process of the knives also play a significant role in their performance. Knives that are precision-engineered and manufactured to tight tolerances ensure smooth cutting and minimal blade deflection. This is crucial for maintaining the integrity of the nails produced and preventing defects in the final product.

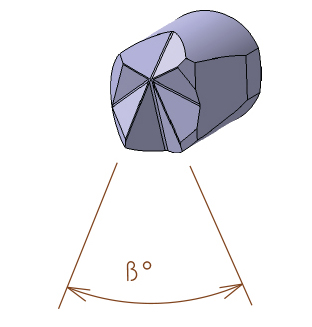

Another important consideration when selecting knives for Enkotec nail making machines is the type of cutting edge. Knives with a sharp, honed edge are able to cut through wire with ease, resulting in clean and precise cuts. Additionally, knives with a serrated edge can be used for cutting harder materials or for creating specific nail shapes.

Regular maintenance and sharpening of knives are also essential for ensuring optimal performance. Dull or damaged knives can result in poor cutting quality, increased energy consumption, and reduced machine efficiency. By regularly inspecting and sharpening the knives, manufacturers can prolong their lifespan and maintain the quality of the nails produced.

In conclusion, the importance of high-quality knives for Enkotec nail making machines cannot be overstated. These knives are essential for ensuring the smooth and efficient operation of the machines, as well as the production of high-quality nails. By selecting knives made from durable materials, precision-engineered designs, and sharp cutting edges, manufacturers can improve the performance and longevity of their Enkotec nail making machines. Regular maintenance and sharpening of knives are also crucial for maintaining optimal performance and reducing production costs. Investing in high-quality knives for Enkotec nail making machines is a wise decision that can lead to improved productivity, reduced downtime, and higher-quality nail production.