Table of Contents

Izinto eziluncedo zokuSebenzisa iimela kumatshini wokwenza izikhonkwane we-Enkotec

Iimela zidlala indima ebalulekileyo ekusebenzeni koomatshini bokwenza iinzipho bakwa-Enkotec. Aba matshini basetyenziswa ngokubanzi kwishishini lokuvelisa ukuvelisa izikhonkwane ezikumgangatho ophezulu ngokufanelekileyo nangempumelelo. Iimela yinxalenye ebalulekileyo yaba matshini, njengoko banoxanduva lokusika kunye nokubumba ucingo ngendlela efunwayo yesikhonkwane. Kweli nqaku, siza kuxubusha iingenelo zokusebenzisa iimela kumatshini wokwenza izikhonkwane we-Enkotec.

Iingcebiso zoLondolozo lweemela kumatshini wokwenza izikhonkwane wase-Enkotec

Indlela yokukhetha iimela eziLungileyo zoomatshini wokwenza izikhonkwane we-Enkotec

Xa kuziwa ekukhetheni iimela ezifanelekileyo kumatshini wakho wokwenza izikhonkwane we-Enkotec, kukho izinto ezininzi ekufuneka uziqwalasele ukuze uqinisekise ukusebenza kakuhle

kunye nexesha elide lomatshini. Iimela ziyinxalenye ebalulekileyo yenkqubo yokwenza izikhonkwane, njengoko zijongene nokusika kunye nokubumba ucingo kwi-nail shape oyifunayo. Ukukhetha iimela ezifanelekileyo kumatshini wakho we-Enkotec kunokwenza umahluko omkhulu kumgangatho kunye nokusebenza kakuhle kwemveliso yakho yezikhonkwane.

Enye yezinto zokuqala ekufuneka uziqwalasele xa ukhetha iimela zomatshini wakho wokwenza izikhonkwane we-Enkotec yimathiriyeli yeemela. Izinto eziphathekayo zeemela ziya kugqiba ukuqina kwazo kunye nokuchasana nokugqoka kunye nokukrazula. Kubalulekile ukukhetha iimela ezenziwe kwizinto eziphezulu ezifana nensimbi yensimbi okanye i-carbide, njengoko ezi zixhobo ziyaziwa ngokuba lukhuni kunye nokukwazi ukugcina umgca obukhali ixesha elide. Utyalo-mali kwiimela ezikumgangatho ophezulu kunokufuna iindleko eziphezulu zangaphambili, kodwa ekugqibeleni kunokukongela imali ekuhambeni kwexesha ngokunciphisa uphindaphindo lokutshintshwa kweemela kunye nexesha lokuphumla.

Enye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha iimela kumatshini wakho we-Enkotec uhlobo isikhonkwane uya kuvelisa. Iimilo ezahlukeneyo zezikhonkwane kunye nobukhulu zifuna iintlobo ezahlukeneyo zeemela ezineeprofayili zokusika ezikhethekileyo. Kubalulekile ukukhetha iimela ezenzelwe ukuvelisa imilo yesikhonkwane oyifunayo, nokuba zizikhonkwane eziqhelekileyo, izikhonkwane zokugqiba, okanye izikhonkwane ezikhethekileyo. Ukusebenzisa uhlobo olungalunganga lweemela kunokukhokelela kumgangatho ombi wezikhonkwane, ukwanda kwenkunkuma, kunye nomonakalo onokwenzeka kumatshini.

Ukongeza kwizinto kunye nohlobo, ubukhulu kunye nobukhulu beemela nazo zibalulekile xa ukhetha iimela zesikhonkwane sakho se-Enkotec. umatshini wokwenza. Ubungakanani beemela kufuneka buhambelane nomatshini kunye nobubanzi bocingo oza kusebenza ngalo. Ukusebenzisa iimela ezincinci okanye ezinkulu kakhulu kunokukhokelela ekusikeni okungafanelekanga kunye nokubunjwa kocingo, okubangela ukuba izikhonkwane ezineziphene kunye nomonakalo onokwenzeka kumatshini. Kubalulekile ukubonisana nencwadana yemigaqo yomatshini okanye umenzi wesikhokelo malunga nobungakanani obufanelekileyo bemela kunye nemilinganiselo yemodeli yakho ye-Enkotec. Iimela ezibuthuntu zinokukhokelela ekusikekeni okungalinganiyo, imiphetho ejijekileyo, kunye nokukhuhlana okwandisiweyo, okunokubangela ukufudumeza okugqithisileyo kunye nokunxiba kwangaphambi kwexesha kwamacandelo omatshini. Ukugcinwa rhoqo kunye nokulolwa kweemela kubalulekile ukuqinisekisa ukuveliswa okufanayo kunye nomgangatho ophezulu we-nail. Utyalo-mali kwinkqubo yokulola imela esemgangathweni okanye iinkonzo zokulola iimela ezingaphandle kunokunceda ukwandisa ubomi beemela zakho kwaye ugcine ukusebenza kakuhle komatshini wakho we-Enkotec.

Ekuqukumbeleni, ukukhetha iimela ezifanelekileyo kumatshini wakho wokwenza izikhonkwane we-Enkotec sisigqibo esibalulekileyo esinoku impembelelo kumgangatho, ukusebenza kakuhle, kunye nobomi obude bemveliso yakho yezikhonkwane. Ngokuqwalasela izinto ezifana nemathiriyeli, uhlobo, ubungakanani, imilinganiselo, kunye nokubukhali, unokuqinisekisa ukuba umatshini wakho usebenza ngokugqibeleleyo kwaye uvelisa izikhonkwane ezikumgangatho ophezulu rhoqo. Utyalo-mali kwiimela ezikumgangatho ophezulu kunye nokugcinwa okufanelekileyo kunokunceda ukwandisa ukusebenza komatshini wakho we-Enkotec kwaye ekugqibeleni ukonge ixesha kunye nemali ekuhambeni kwexesha.

When it comes to choosing the right knives for your Enkotec Nail Making Machine, there are several factors to consider in order to ensure optimal performance

and longevity of the machine. Knives are a critical component of the nail making process, as they are responsible for cutting and shaping the wire into the desired nail shape. Selecting the right knives for your Enkotec machine can make a significant difference in the quality and efficiency of your nail production.

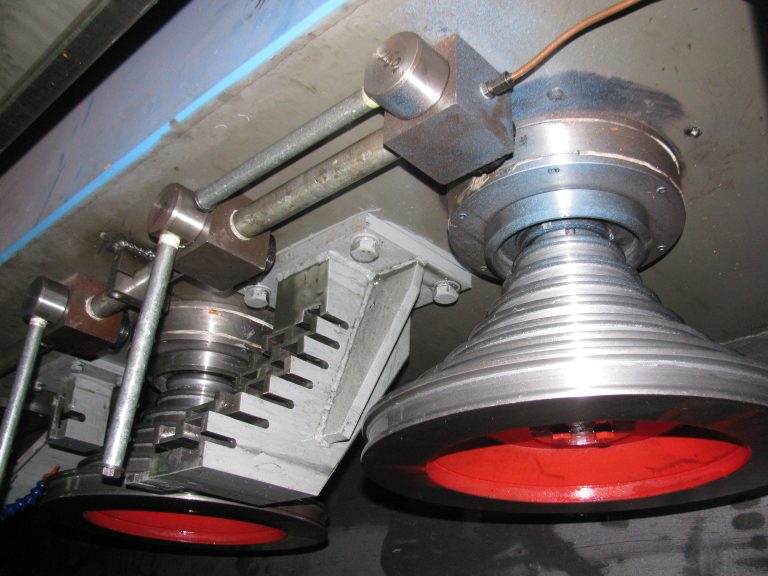

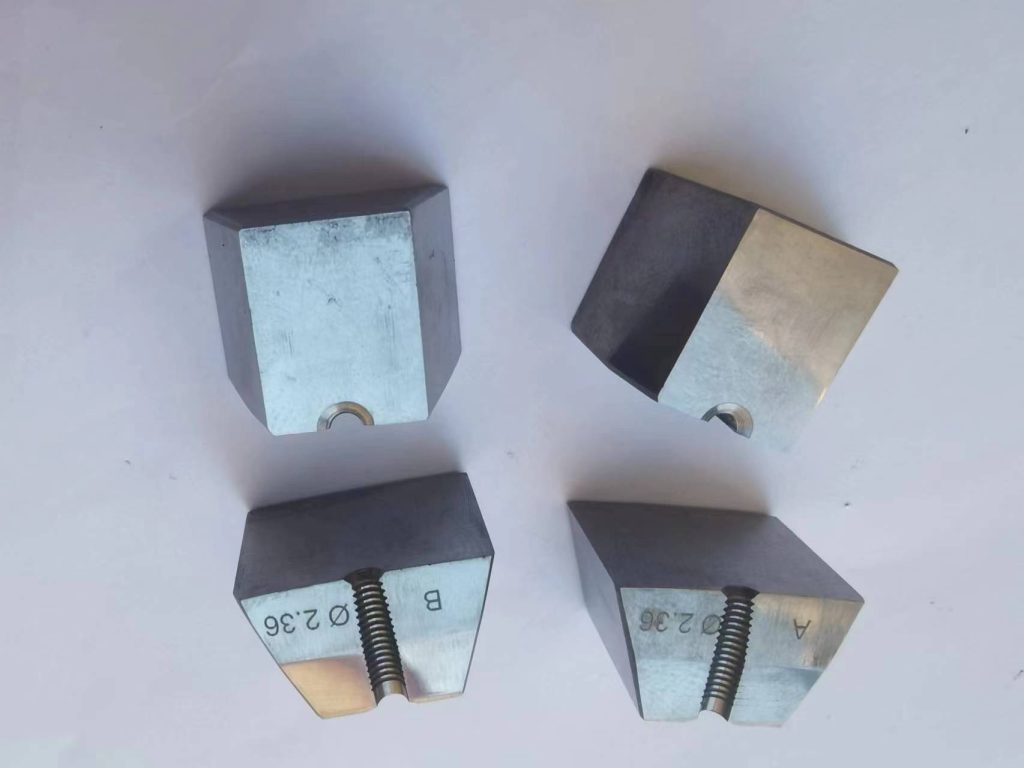

One of the first things to consider when choosing knives for your Enkotec nail making machine is the material of the knives. The material of the knives will determine their durability and resistance to wear and tear. It is important to choose knives made from high-quality materials such as tool steel or carbide, as these materials are known for their hardness and ability to maintain a sharp edge for a longer period of time. Investing in high-quality knives may require a higher upfront cost, but it can ultimately save you money in the long run by reducing the frequency of knife replacements and downtime.

Another important factor to consider when selecting knives for your Enkotec machine is the type of nail you will be producing. Different nail shapes and sizes require different types of knives with specific cutting profiles. It is essential to choose knives that are designed to produce the specific nail shape you need, whether it be common nails, finishing nails, or specialty nails. Using the wrong type of knives can result in poor nail quality, increased waste, and potential damage to the machine.

In addition to material and type, the size and dimensions of the knives are also crucial considerations when choosing knives for your Enkotec nail making machine. The size of the knives should be compatible with the machine and the wire diameter you will be working with. Using knives that are too small or too large can lead to improper cutting and shaping of the wire, resulting in defective nails and potential damage to the machine. It is important to consult the machine’s manual or manufacturer for guidance on the appropriate knife size and dimensions for your specific Enkotec model.

Furthermore, the sharpness of the knives is a key factor in the performance of your Enkotec nail making machine. Dull knives can lead to uneven cuts, jagged edges, and increased friction, which can cause overheating and premature wear of the machine components. Regular maintenance and sharpening of the knives are essential to ensure consistent and high-quality nail production. Investing in a quality knife sharpening system or outsourcing knife sharpening services can help prolong the life of your knives and maintain the efficiency of your Enkotec machine.

In conclusion, choosing the right knives for your Enkotec nail making machine is a critical decision that can impact the quality, efficiency, and longevity of your nail production. By considering factors such as material, type, size, dimensions, and sharpness, you can ensure that your machine operates at its best and produces high-quality nails consistently. Investing in high-quality knives and proper maintenance can help maximize the performance of your Enkotec machine and ultimately save you time and money in the long run.