Table of Contents

Izinto eziluncedo zokuSebenzisa uMatshini we-Horizontal Spooling kwi-Industrial Applications

Indlela yokuGcina ngokuchanekileyo kunye nokuJonga iNgxaki ngoomatshini othe tyaba wokuSpooling kwiSeti yokuVelisa

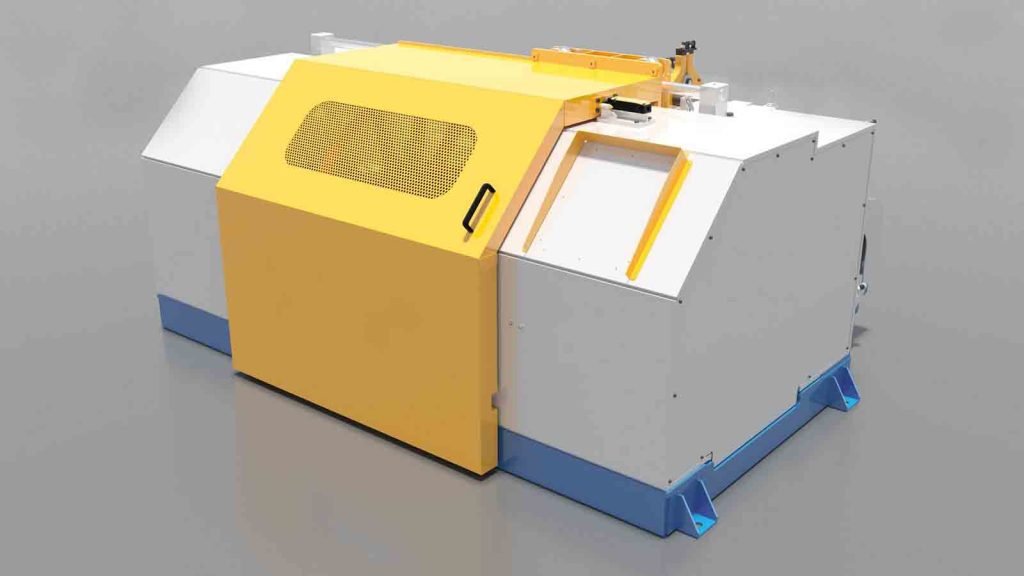

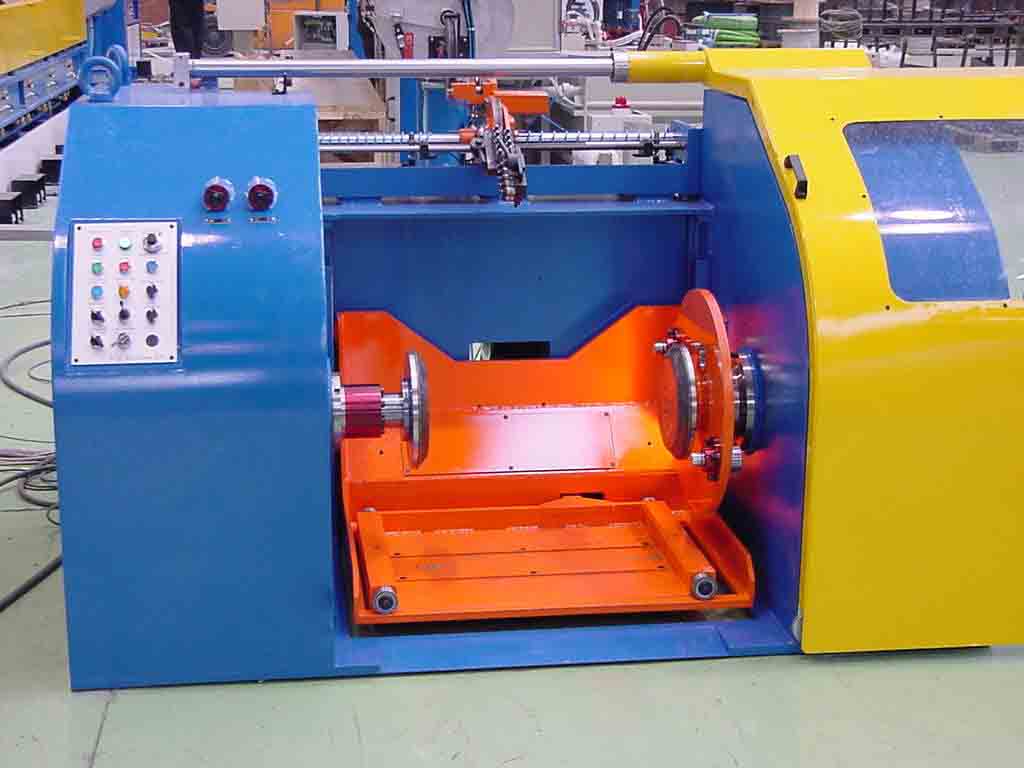

Oomatshini be-spooling abathe tyaba sisixhobo esiyimfuneko kwiindawo ezininzi zokuvelisa, ezisetyenziselwa izinto zokujija ezifana nocingo, intambo, intambo, okanye iityhubhu kwi-spool okanye i-reel. Ukugcinwa okufanelekileyo kunye nokusombulula ingxaki kwaba matshini kubalulekile ukuze kuqinisekiswe ukusebenza kakuhle kwaye kuthintelwe ukwehla kweendleko. Kweli nqaku, siza kuxoxa ngeengcebiso eziphambili malunga nokugcina ngokufanelekileyo kunye nokulungisa ingxaki kumatshini wokuhlamba othe tye kwindawo yokuvelisa.

Ukugcinwa rhoqo kubalulekile ukugcina umatshini we-bobbin othe tye osebenza ngokufanelekileyo. Omnye weyona misebenzi ibalulekileyo yolondolozo kukuhlola rhoqo nokucoca umatshini. Uthuli, inkunkuma, kunye nezinye izinto ezingcolisayo zinokwakhelana kumalungu omatshini, nto leyo ekhokelela kukungasebenzi kakuhle nokuncipha kokusebenza. Ukucocwa rhoqo ngebrashi ethambileyo okanye ilaphu kunokuncedisa ukuthintela le miba.

Ngaphezu kokucoca, kubalulekile ukuthambisa rhoqo iindawo ezihambayo zomatshini. Ukuthambisa okufanelekileyo kunokunceda ukunciphisa ukungqubana nokunxiba, ukwandisa ubomi bomatshini kunye nokuqinisekisa ukusebenza kakuhle. Qiniseka ukuba usebenzisa uhlobo oluchanekileyo lwesithambiso esicetyiswa ngumvelisi kwindawo nganye ethile yomatshini.

Omnye umsebenzi obalulekileyo wokulondoloza kukujonga rhoqo izicwangciso zoxinzelelo kumatshini. Uxinzelelo olufanelekileyo lubalulekile ekufumaneni iziphumo ezingaguqukiyo. Ukuba uxinzelelo luphezulu kakhulu okanye luphantsi kakhulu, lunokukhokelela kumoya ongalinganiyo, ama-snags, okanye eminye imiba. Qinisekisa ukuba ulungelelanisa izicwangciso zoxinzelelo njengoko kufuneka ukuze uqinisekise ukusebenza kakuhle.

Ngaphezu kokugcinwa rhoqo, kubalulekile ukulungisa ingxaki enokuthi ivele ngomatshini othe tye otyumzayo. Umba omnye oxhaphakileyo kukujika-jika kokungalingani, okunokubangelwa zizinto ezahlukeneyo ezifana nokusetha uxinezeleko olungafanelekanga, izinto ezigugileyo, okanye i-spools engahambi kakuhle. Ukucombulula lo mba, qala ngokujonga iisetingi zoxinzelelo kwaye uzilungise njengoko kufuneka. Ukuba ingxaki iyazingisa, hlola umatshini ukujonga naziphi na iindawo ezigugileyo okanye ezonakeleyo ezinokufuna ukutshintshwa.

Omnye umba oxhaphakileyo ngoomatshini bokuhlamba abathe tyaba kukuxinana. I-Jamming ingenzeka xa into efakwa kwi-spool ixinga okanye iphithene. Ukucombulula le ngxaki, okokuqala, misa umatshini kwaye ususe ngononophelo nayiphi na into ephothiweyo. Hlola umatshini ukuba kukho naziphi na izithintelo okanye izinto ezingalungelelanisiweyo ezinokubangela ukuxinana. Emva kokuba umba usonjululwe, qalisa ngokutsha umatshini kwaye uwubeke iliso ngokusondeleyo ukuze uqinisekise ukuba ingxaki ayiphindi.

Ekuqukunjelweni, ukugcinwa okufanelekileyo kunye nokusombulula ingxaki kubalulekile ekuqinisekiseni ukusebenza kakuhle komatshini wokuhlamba othe tye kwindawo yokuvelisa. Ngokuhlola rhoqo kunye nokucoca umatshini, ukuthambisa iindawo ezihambayo, ukujonga izicwangciso zokuxinana, kunye nokulungisa nayiphi na imiba evelayo, unokunceda ukuthintela ukuchithwa kweendleko kunye nokuqinisekisa ukuba umatshini uyaqhubeka nokusebenza ngokusemandleni awo. Khumbula ukulandela izikhokelo zomenzi zolungiso kunye nokusombulula ingxaki ukugcina umatshini wakho othe tyaba wokuspoola ukwimeko ephezulu.

Horizontal Spooling Machines are essential equipment in many manufacturing settings, used for winding materials such as wire, cable, rope, or tubing onto a spool or reel. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and prevent costly downtime. In this article, we will discuss some key tips on how to properly maintain and troubleshoot a horizontal spooling machine in a manufacturing setting.

Regular maintenance is essential to keep a horizontal Respooling Bobbin Machine running smoothly. One of the most important maintenance tasks is to regularly inspect and clean the machine. Dust, debris, and other contaminants can build up on the machine’s components, leading to malfunctions and decreased performance. Regular cleaning with a soft brush or cloth can help prevent these issues.

In addition to cleaning, it is important to regularly lubricate the moving parts of the machine. Proper lubrication can help reduce friction and wear, extending the life of the machine and ensuring smooth operation. Be sure to use the correct type of lubricant recommended by the manufacturer for each specific part of the machine.

Another important maintenance task is to regularly check the tension settings on the machine. Proper tension is crucial for achieving consistent winding results. If the tension is too high or too low, it can lead to uneven winding, snags, or other issues. Make sure to adjust the tension settings as needed to ensure optimal performance.

In addition to regular maintenance, it is important to troubleshoot any issues that may arise with the horizontal spooling machine. One common issue is uneven winding, which can be caused by a variety of factors such as improper tension settings, worn-out components, or misaligned spools. To troubleshoot this issue, start by checking the tension settings and adjusting them as needed. If the problem persists, inspect the machine for any worn or damaged parts that may need to be replaced.

Another common issue with horizontal spooling machines is jamming. Jamming can occur when the material being wound onto the spool gets stuck or tangled. To troubleshoot this issue, first, stop the machine and carefully remove any tangled material. Inspect the machine for any obstructions or misaligned components that may be causing the jamming. Once the issue is resolved, restart the machine and monitor it closely to ensure that the problem does not recur.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the smooth operation of a horizontal spooling machine in a manufacturing setting. By regularly inspecting and cleaning the machine, lubricating moving parts, checking tension settings, and troubleshooting any issues that arise, you can help prevent costly downtime and ensure that the machine continues to perform at its best. Remember to follow the manufacturer’s guidelines for maintenance and troubleshooting to keep your horizontal spooling machine in top condition.